Many companies enter Q1 reacting to challenges instead of planning around them. Timelines compress, component availability surprises become problems, and manufacturing partnerships that could have been proactive turn reactive.

The decisions you make early in 2026 about design finalization, component selection, and electronic manufacturing services partnerships shape your cost structure, lead times, and flexibility for the entire year. While 2026 won’t be defined by a single disruptive event, it will be shaped by compounding pressures: supply chain evolution, labor availability, timeline realities, and increasing product complexity.

In this article we discuss what businesses planning electronics projects in 2026 should keep on their radar so they can plan proactively rather than react constantly. Whether you’re evaluating EMS providers or finalizing product roadmaps, understanding these trends helps you make better decisions.

Here’s what decision-makers should be prepared for.

TL;DR

- Component supply is stable but strategic. Long-tail and specialized parts still carry risks; early BOM validation prevents costly late-stage substitutions.

- Early EMS partnerships are becoming standard. Manufacturers prioritize collaborative relationships; waiting until designs are “final” compresses timelines unnecessarily.

- Enclosures aren’t afterthoughts. Integrated electronics and sheet metal manufacturing eliminate coordination delays that plague multi-vendor builds.

- Lead times depend on planning, not just capacity. Realistic timelines, clear documentation, and proactive communication matter more than raw production speed.

- 2026 success is built now. Early conversations about component availability, manufacturing approaches, and realistic schedules prevent Q1 firefighting.

Component Supply in 2026: More Stable, Still Strategic

Component availability has stabilized significantly compared to the extreme shortages of recent years. The days of 52-week lead times on standard parts have largely passed. However, “more stable” doesn’t mean frictionless, and strategic component planning remains essential.

Legacy parts, specialized components, and redesign-driven substitutions continue to affect project timelines. The risks have shifted from broad shortages to specific, hard-to-predict component availability challenges. Long-tail components (niche parts used in specific applications with lower production volumes) can still carry extended lead times or face obsolescence without warning.

What matters most in 2026 isn’t stockpiling components or panic buying. It’s forecast accuracy and early Bill of Materials (BOM) validation. Late-stage BOM changes remain one of the most expensive timeline killers. When a component becomes unavailable after design finalization, the scramble to find alternates, revalidate designs, and update documentation compresses schedules and inflates costs.

Working with electronic manufacturing services partners who have sourcing visibility helps reduce these surprises. Early component review (before designs are locked) identifies potential availability issues while there’s still time to make informed decisions rather than emergency substitutions.

The message for 2026: Component supply is manageable, but only with proactive planning. Reactive fixes cost more in both time and money.

Locking in Electronic Manufacturing Services Partners Earlier Is Becoming the Norm

The biggest manufacturing risk in 2026 won’t be lack of production capacity. It will be a lack of alignment between what you need and what your manufacturing partner can deliver within your timeline.

Manufacturers are increasingly prioritizing predictable, collaborative partnerships over transactional project-to-project builds. This shift reflects a broader industry reality: production planning requires visibility, and visibility requires commitment from both parties.

Early electronic manufacturing services involvement provides several advantages that waiting until designs are “final” simply can’t match:

Design feedback during development catches manufacturability issues before they become production problems. A quick review during the design phase can identify component placement challenges, tolerance issues, or assembly constraints that would otherwise surface during first article inspection, when changes are expensive and time-consuming.

Timeline realism from the start means your schedules reflect actual component availability and production capacity, not optimistic assumptions. When your circuit board assembly partner checks component lead times during quoting rather than after you’ve committed, you avoid the frustrating scenario of discovering a 12-week component delay after promising delivery in 8 weeks.

Cost predictability improves when manufacturers understand your volume expectations, quality requirements, and timeline constraints upfront. Late engagement often leads to rushed quotes based on incomplete information, creating budget surprises during production.

The companies that will navigate 2026 most smoothly are already having these conversations—not because they have finalized designs, but because they understand that waiting until designs are “complete” often compresses schedules unnecessarily.

Manufacturing partnerships built on early collaboration consistently outperform relationships that start with a finished design file and a demand for a quick quote.

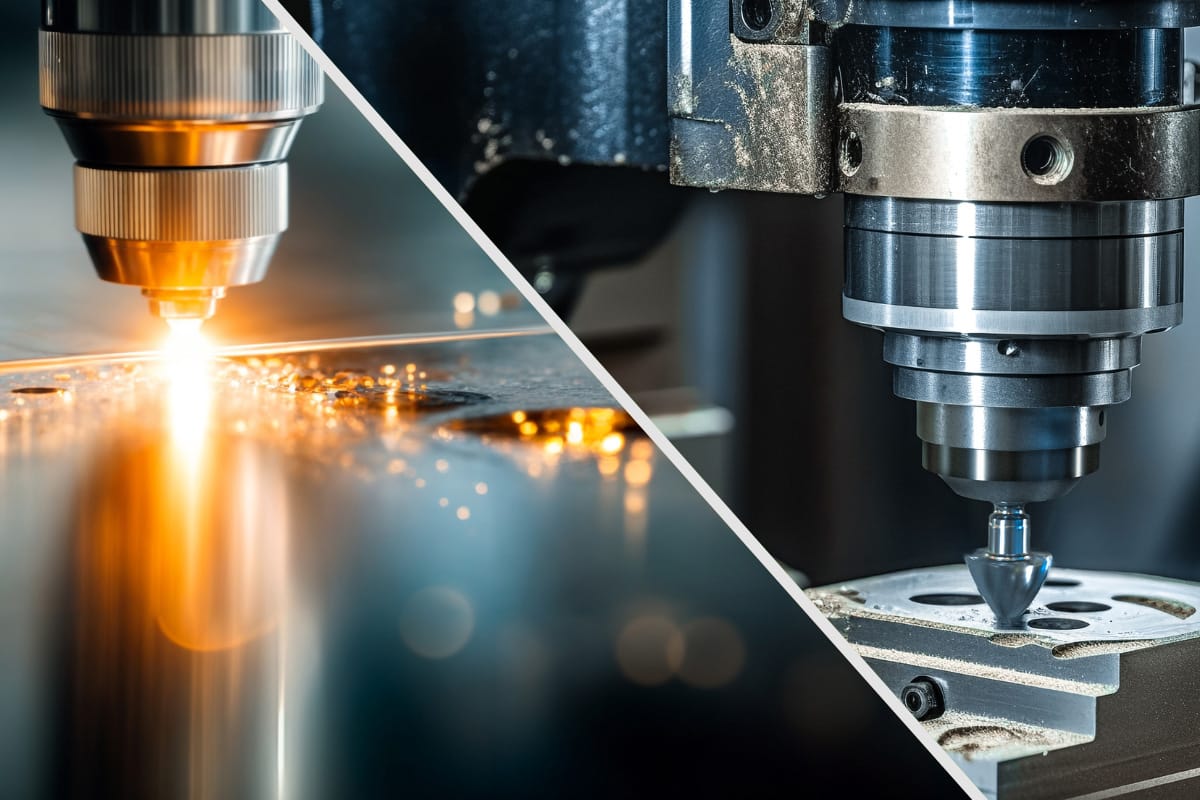

Sheet Metal and Enclosure Decisions Affecting Electronics Projects

Enclosures and mechanical integration are no longer afterthoughts in electronics projects. In 2026, the companies that treat electronics and enclosures as separate, sequential decisions will face timeline challenges that integrated approaches avoid.

Demand continues growing for integrated electronics and enclosure manufacturing under one roof. When PCB assembly and sheet metal fabrication happen at the same facility with unified project management, coordination delays disappear. Components don’t ship between vendors, schedules don’t require alignment across multiple companies, and design changes don’t require updates to multiple partners.

Sheet metal fabrication remains cost-effective for many electronics housings, particularly for:

- Industrial equipment enclosures requiring durability

- Control panels and junction boxes

- Custom mounting brackets and chassis

- Mid-volume production where tooling costs need to stay reasonable

However, design-for-manufacturing (DFM) decisions matter more than ever. The enclosure design choices you make (material selection, bend radii, hole placements, finishing requirements) directly affect both cost and lead time. An enclosure designed without manufacturing input often requires expensive modifications during production or creates assembly challenges that slow the entire build.

CNC machining still plays an important role, particularly for:

- Prototypes requiring quick turnaround before committing to production tooling

- Lower volumes where complex custom tooling would be required for sheet metal fabrication

- Complex geometries that benefit from machining capabilities

The pattern companies should watch for? Poor enclosure decisions often delay otherwise-ready electronics builds. Your boards might be perfect, but if the enclosure fabrication isn’t coordinated with the same attention, the entire project waits.

The takeaway for 2026: Treat your electronics and mechanical integration as one system from the start, not two separate projects that need to eventually work together.

Lead Times, Labor, and Automation: What to Expect in 2026

When companies ask about lead times in 2026, they’re usually thinking about machines and production capacity. But manufacturing timelines aren’t just about equipment availability. They’re also about the people, processes, and planning that keep production flowing.

Lead times are influenced by several factors that won’t dramatically change in 2026:

Labor availability continues to shape production scheduling. Skilled technicians, quality inspectors, and assembly operators remain essential even in highly automated facilities. Manufacturers who have invested in training and retention programs offer more reliable scheduling than those constantly dealing with workforce turnover.

Production sequencing and scheduling bottlenecks affect how quickly your project moves through the facility. A manufacturer with efficient scheduling and balanced workloads can often deliver faster than one with more equipment but poor planning.

Automation continues expanding, particularly in repetitive, high-volume processes like component placement and solder paste application. However, automation doesn’t eliminate the need for skilled technicians. Human expertise remains critical for quality control, complex assembly operations, troubleshooting, and handling the variations that automated systems can’t manage.

The reality is that “fast” still depends on preparation, documentation, and coordination more than raw production speed. A manufacturer with automated pick-and-place equipment still needs complete BOMs, clear assembly instructions, and readily available components to deliver quickly.

This is why realistic timelines beat optimistic promises. A manufacturer who tells you exactly where time is spent demonstrates process understanding. Vague timelines or promises that sound too good often reflect wishful thinking rather than actual production planning.

Communication and planning matter more than speed claims. The manufacturers who consistently deliver on schedule are those who identify potential delays early, communicate proactively, and build schedules based on what’s actually achievable rather than what sounds impressive.

What This Means for Companies Planning 2026 Electronics Projects

If you’re mapping electronics projects for 2026, here’s what matters most:

Plan earlier than feels necessary. The gap between “we should start thinking about manufacturing” and “we need quotes now” should be months, not weeks. Early conversations don’t lock you into commitments, but they do provide the visibility needed to make better decisions.

Validate designs before schedules tighten. Design for manufacturability (DFM) reviews during development prevent expensive changes during production. A $500 design consultation can prevent $5,000 in rework and schedule delays.

Choose partners who communicate clearly. Manufacturing relationships built on transparency and proactive updates consistently outperform those where you’re chasing status information. If your manufacturer only tells you about problems when you ask, you’re always behind.

Treat electronics and enclosures as one system. Sequential decisions (finish the boards, then figure out the housing) add coordination time and complexity. Integrated approaches eliminate handoffs and reduce total project timelines.

Build flexibility into timelines and sourcing. The most resilient plans account for component availability changes, design iterations, and testing requirements. Buffer time isn’t pessimism…it’s realistic planning.

Verify component availability early. Don’t assume parts are readily available just because they’re specified in your design. Component verification during design prevents timeline surprises during production.

Document clearly and completely. Incomplete documentation creates delays while manufacturers wait for clarifications. Clear BOMs, assembly instructions, and testing requirements speed every phase of production.

These are practices that separate projects that proceed smoothly from those that face constant firefighting.

Planning 2026 Projects Starts With Better Conversations

Success in manufacturing isn’t about predicting the future. It’s about building relationships, processes, and timelines that can handle the challenges that inevitably arise.

The companies that navigate 2026 most effectively won’t be those who waited for perfect information before engaging with electronic manufacturing services partners. They’ll be the ones who started conversations early, validated assumptions before committing to timelines, and built partnerships based on collaboration rather than transactions.

Early discussions don’t lock you into commitments, but they do protect you from avoidable problems. A conversation in December or January about component availability, realistic timelines, and manufacturing approaches provides visibility that rushing into production in March simply can’t match.

At IMS, we help teams plan realistically, not reactively. Whether you’re finalizing 2026 product roadmaps, evaluating electronic manufacturing services partnerships, or mapping electronics projects that need to deliver on schedule, early conversations create better outcomes.

Our integrated approach—handling both circuit board assembly and sheet metal fabrication under one roof—eliminates the coordination challenges that multi-vendor builds create. Our established quality systems, component sourcing relationships, and process expertise help projects move from design to delivery without the surprises that derail schedules.

If you’re mapping electronics projects for 2026, a conversation now can save months later. Our team can provide realistic timeline estimates, component availability insights, and manufacturing approach recommendations based on your specific requirements.

Contact IMS today to discuss your 2026 planning and learn how we can support your projects.