In the fast-paced and highly competitive electronics market, selecting the right circuit board assembly partner is crucial. This decision can significantly influence product quality, innovation potential, and overall market success.

Circuit board assemblies are the backbone of various industries, including automotive, aerospace, and consumer electronics. This importance means that choosing a CBA partner is a strategic move that requires careful consideration.

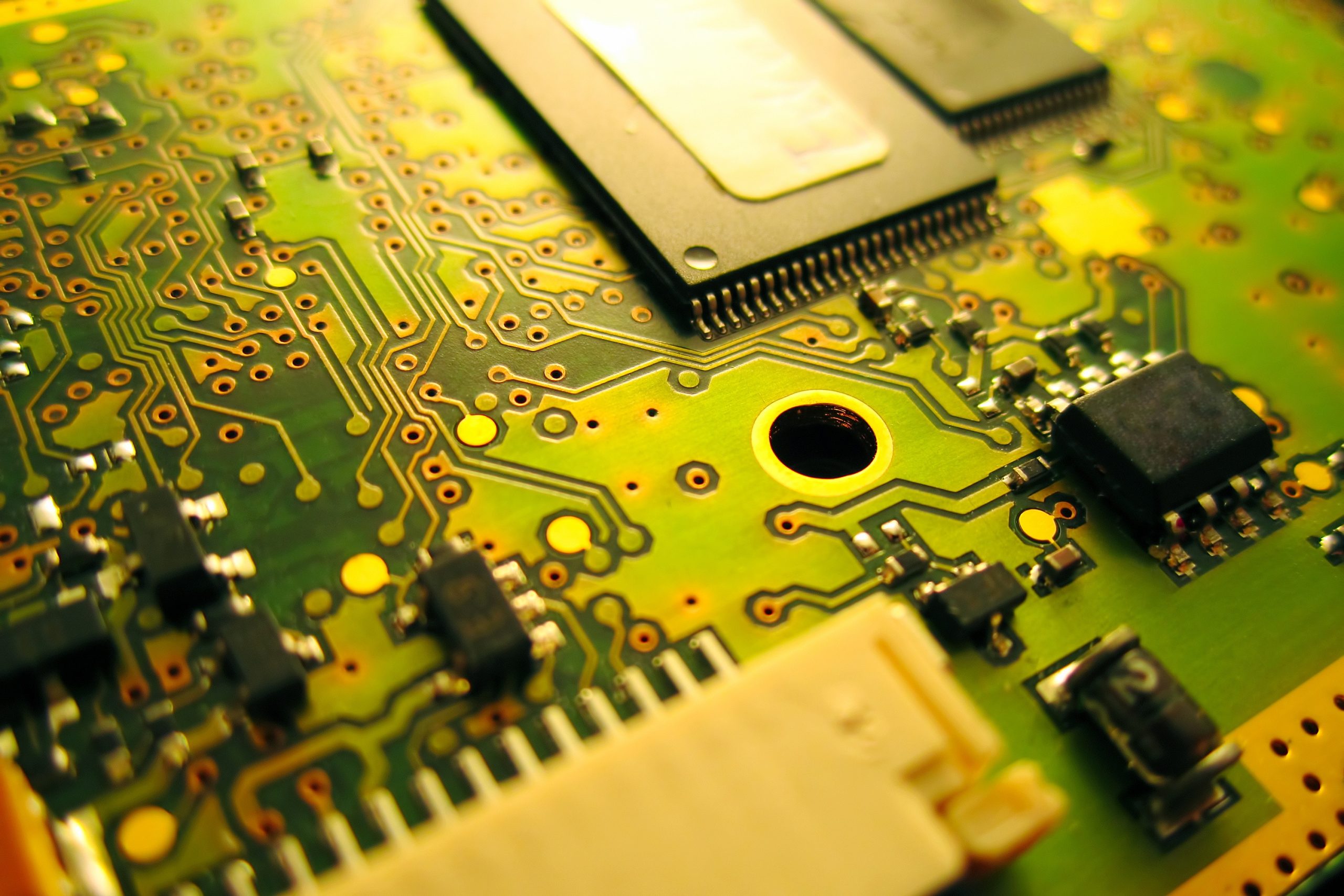

Understanding Circuit Board Assembly

Circuit board assembly involves attaching electronic components to a printed circuit board (PCB) to create a functional electronic assembly. This process is critical to producing a wide range of electronic devices, from simple consumer gadgets to complex industrial machinery.

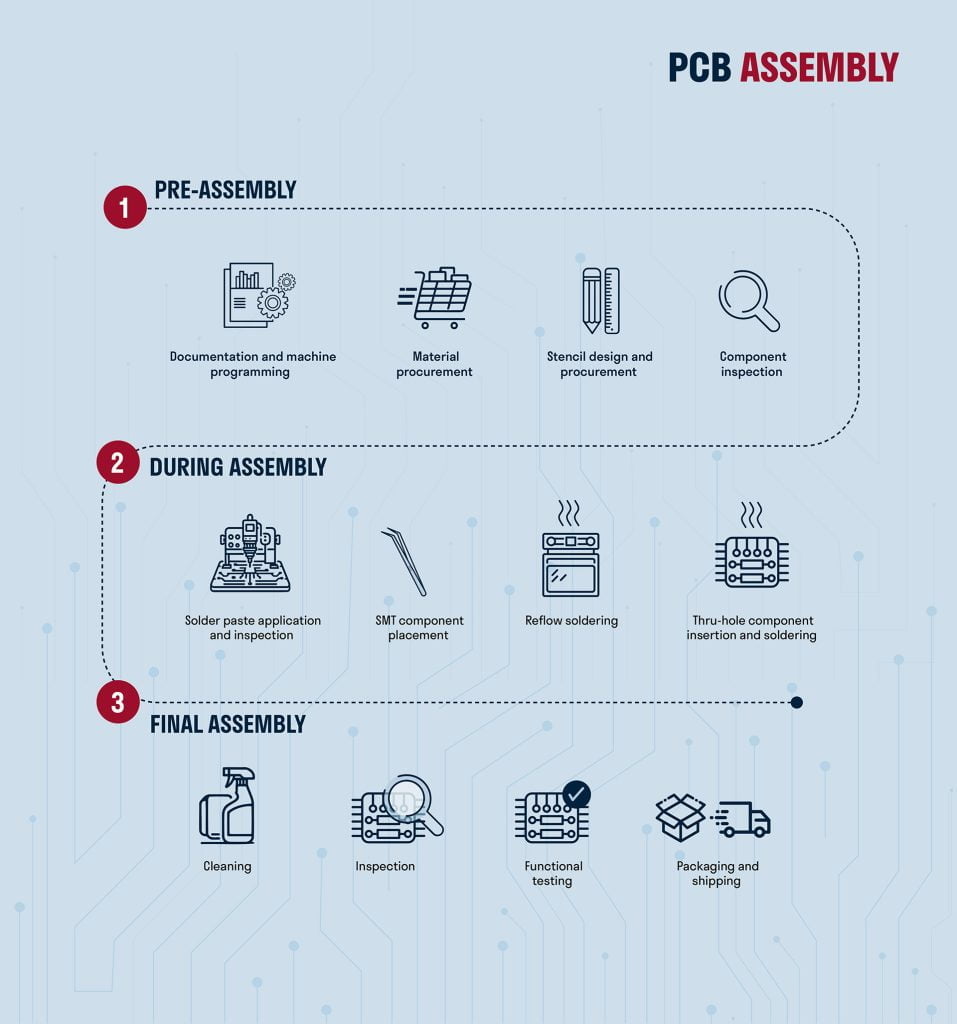

At IMS, the circuit board assembly process happens in three main stages:

Types of Circuit Board Assemblies

Understanding the different types of CBAs is essential for selecting the right partner. Each type offers unique advantages and is suited to specific applications:

Surface Mount Technology (SMT)

- Components are mounted directly onto the surface of the PCB.

- Enables high-density designs and automated production processes.

- Ideal for compact and complex electronics.

Through-Hole Technology (THT)

- Components are placed through holes drilled into the PCB and soldered on the opposite side.

- Provides stronger mechanical bonds and reliability.

- Suitable for products requiring durability and robustness.

Hybrid (Combination of SMT and THT)

- Combines the benefits of both SMT and THT.

- Allows for greater design flexibility and robustness.

- Used in applications where both high-density and strong mechanical bonds are needed.

Key Factors to Consider When Choosing a Circuit Board Assembly Partner

Quality Assurance

Quality assurance is a non-negotiable aspect of circuit board assembly. Your CBA partner must adhere to industry certifications such as ISO 9001:2015 and IPC standards. These certifications ensure rigorous quality control processes and comprehensive testing protocols, guaranteeing that every product meets high-quality standards. A partner committed to quality will embed these practices into every step of their production process, from sourcing raw materials to final testing and packaging.

Technical Capabilities

When evaluating potential CBA partners, it is crucial to consider their technical capabilities. Assess the range of services they offer, from prototyping to full-scale production. Examine their expertise in handling complex designs and advanced technologies, such as high-speed Surface Mount Technology (SMT) lines and sophisticated inspection equipment like Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI). A technically capable partner will be equipped to manage the intricacies of modern electronic assemblies with precision and efficiency.

Experience and Reputation

Track record and industry reputation are vital signs of reliability and expertise. Look for testimonials, case studies, and industry awards to gauge their standing. An experienced partner will have a proven history of successful projects and a deep understanding of industry trends and challenges. Their longevity in the market often reflects their ability to adapt and excel in a competitive landscape.

Flexibility and Scalability

In today’s fast-paced market, flexibility and scalability are essential. Your CBA partner should be able to accommodate varying production volumes, from low-volume prototypes to high-volume production runs. They should also offer customization options and rapid response times to adapt to market changes or project-specific needs. A flexible and scalable partner ensures your production can ramp up or down as required without compromising quality or timelines.

Cost Efficiency

While cost is a significant factor, it’s essential to balance cost with quality and reliability. Understand the pricing structure of potential partners, including any hidden costs that may arise. A cost-effective CBA partner will offer competitive pricing without compromising on the quality of their services. They should provide a clear and transparent cost breakdown, allowing you to make informed decisions that align with your budget.

Communication and Support

Transparent and consistent communication is vital for a successful partnership. Ensure that your CBA partner provides clear and timely updates throughout the project lifecycle. Effective communication fosters a collaborative environment where potential issues can be addressed promptly. Additionally, post-production support is crucial to handle any challenges that may arise after delivery, ensuring long-term satisfaction and reliability.

Evaluating Potential CBA Partners

Initial Research

Start by identifying potential CBA partners through industry networks, trade shows, and online research. Create a shortlist based on their capabilities, reputation, and alignment with your project requirements. Leverage professional networks and industry associations to gather recommendations and insights about potential partners. This initial step is crucial for narrowing your options to those that best meet your needs.

Request for Proposal (RFP) Process

Craft a detailed Request for Proposal (RFP) to solicit bids from potential partners. Your RFP should include questions about their quality assurance processes, technical capabilities, experience, scalability, and pricing structure. Be specific about your project requirements and expectations to ensure you receive comprehensive and comparable responses. A well-crafted RFP allows you to assess potential partners on a standardized basis, making it easier to evaluate their suitability.

Site Visits and Audits

Conduct site visits to evaluate the facilities and processes of potential partners. Use a checklist to assess their equipment, quality control measures, and overall operational efficiency. During the visit, observe their production environment, speak with their team, and review their adherence to industry standards. This hands-on evaluation provides valuable insights into their operational capabilities and commitment to quality.

Benefits of Partnering with the Right CBA Provider

Enhanced Product Quality

A high-quality CBA partner ensures that every assembled circuit board meets stringent quality standards, directly impacting the performance and reliability of your products. By leveraging advanced technologies and robust quality control processes, a reliable partner guarantees that your products are built to last, reducing the risk of defects and failures.

Operational Efficiency

The right partner streamlines production processes, reducing time-to-market and increasing overall operational efficiency. This enables you to focus on core business activities while ensuring timely project completion. Efficient production workflows and effective resource management by your CBA partner contribute to smoother operations and faster turnaround times.

Innovation and Competitive Advantage

Access to cutting-edge technologies and innovative solutions provided by a top-tier CBA partner can give your products a significant competitive edge. This fosters continuous innovation and keeps your business ahead of industry trends. A forward-thinking partner will collaborate with you to explore new possibilities and implement state-of-the-art solutions that enhance your product offerings.

Risk Mitigation

Partnering with a reliable CBA provider reduces the risk of defects, recalls, and production delays. Their expertise in quality control and problem-solving ensures that potential issues are addressed proactively. A dependable partner will have contingency plans and risk management strategies in place to handle unforeseen challenges, safeguarding your production schedule and product quality.

About IMS Electronics Manufacturing

IMS Electronics Manufacturing stands out as a premier CBA partner, combining 20 years of experience with state-of-the-art technology to deliver exceptional results. Our advanced SMT lines, equipped with in-line Solder Paste Inspection (SPI) and Automated Optical Inspection (AOI), ensure ultimate accuracy and precision. We offer a comprehensive range of services, from low-volume prototypes to high-volume production runs, tailored to meet your unique needs.

Our commitment to quality is reflected in our adherence to rigorous QA standards, including ISO 9001:2015 and IPC Class 2 and 3. With continuous improvement at the core of our operations, we exceed industry standards and client expectations consistently. Learn more about our unmatched quality standards.

Your Ideal Circuit Board Assembly Partner

Choosing the right circuit board assembly partner is crucial for your business’s success. By focusing on quality assurance, technical capabilities, experience, flexibility, cost efficiency, and communication, you ensure a partnership that drives superior product quality and innovation.

At IMS Electronics Manufacturing, we exceed expectations with advanced technology, stringent quality standards, and innovative solutions. Our experience and dedication to excellence make us the ideal partner to help you navigate the complexities of circuit board assembly.

Contact IMS Electronics Manufacturing today to discuss your needs and discover how our tailored solutions can drive your business toward greater success. Let’s build the future together!