When people think about electronic manufacturing services (EMS), assembly is usually the first thing that comes to mind. But true full-service EMS offers much more, delivering end-to-end solutions that cover everything from design and sourcing to testing and post-production.

This comprehensive approach brings unparalleled quality and efficiency, streamlining complex projects and allowing manufacturers to focus on innovation without the burdens of handling each phase themselves.

For companies in industries like automotive, medical devices, aerospace, and consumer electronics, full-service EMS is a game-changer. This article explores what sets full-service electronic manufacturing apart from basic assembly, highlighting the value added at each stage.

What Makes Full-Service EMS Different?

While assembly is a core part of EMS, it’s only one component of the bigger picture. Full-service EMS providers offer complete, integrated solutions that reduce handoffs, ensure consistency, and ultimately result in higher-quality products. By managing every phase under one roof, they provide seamless communication and optimized workflows.

The Stages of Full-Service EMS

1. Design and Engineering Support

Full-service EMS providers start with design support, offering expertise that helps refine product concepts and prepare them for efficient manufacturing. They guide you through PCB layout, CAD modeling, and even prototyping, ensuring the design is ready for the production line. With their engineering insights, potential issues can be identified and corrected before full-scale production, saving both time and resources.

2. Material Sourcing and Supply Chain Management

Managing the supply chain for electronics can be complex and costly, especially for specialized components. Full-service EMS providers take on this responsibility, leveraging their relationships with suppliers to secure high-quality materials at competitive prices. They handle logistics, lead times, and quality control, so you receive reliable parts when and where you need them.

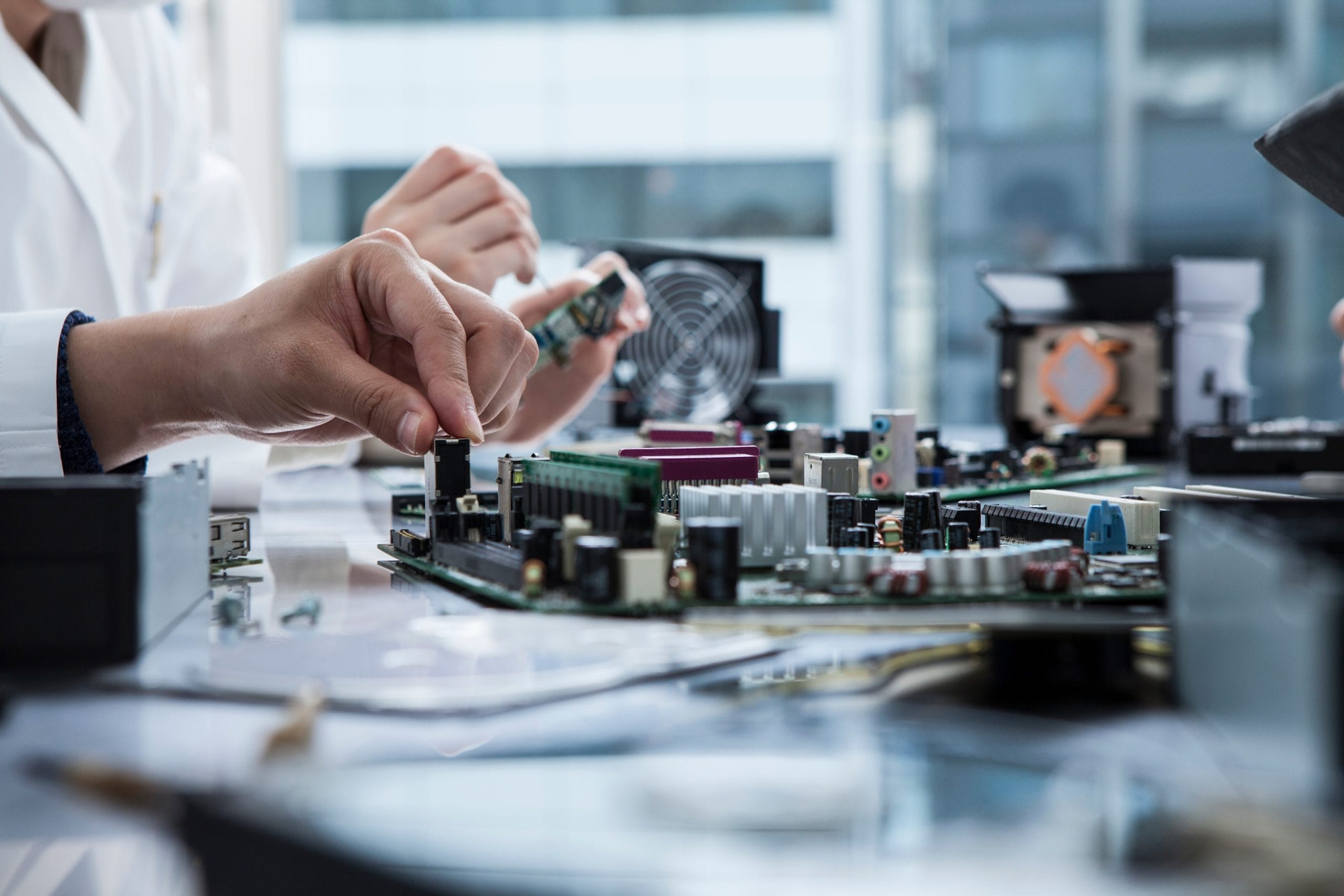

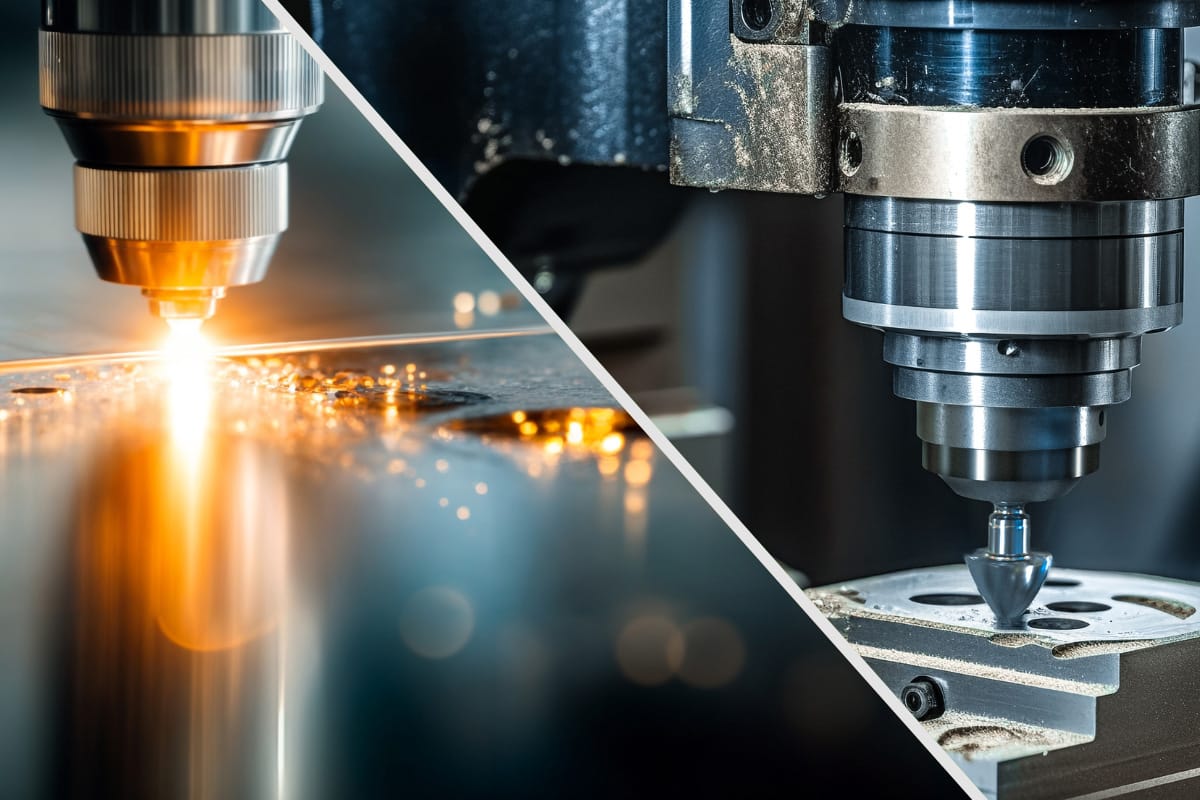

3. Precision Assembly and Production

Assembly is where the magic of turning designs into tangible products happens, and full-service EMS providers bring advanced capabilities to this stage. From Surface Mount Technology (SMT) and Through-Hole Assembly to cable assemblies, full box build assemblies, and metal fabrication of enclosures, they deliver precision and consistency that ensure your products meet high standards. The depth of experience in various assembly techniques results in reliability and long-lasting performance in every piece.

4. Testing and Quality Assurance

Testing is a critical component of quality control in EMS, and full-service providers take this stage seriously. They offer functional testing, in-circuit testing, and environmental stress screening, ensuring your product can withstand real-world conditions. By catching potential issues early, they prevent costly errors and build confidence in the product’s performance and durability.

5. Post-Production and Lifecycle Support

The journey doesn’t end when assembly is complete. Full-service EMS providers go beyond production with post-production support services, including packaging, warehousing, and logistics. Many also offer repair and warranty support, giving you peace of mind that your products are cared for throughout their lifecycle.

Industry-Specific EMS Capabilities

Full-service electronic manufacturing services (EMS) offer tailored solutions to meet the unique demands of various industries. By providing comprehensive support from design to post-production, full-service EMS providers ensure that products meet your industry’s standards while also excelling in performance and reliability.

✓ Renewable Energy

In the renewable energy sector, full-service EMS providers develop and manufacture solar panel controllers and wind turbine electronics. These components are designed to withstand harsh environmental conditions, ensuring efficient energy conversion and long-term reliability.

✓ Marine and Ocean Engineering

For marine applications, EMS providers create navigational control systems and subsea sensor assemblies. These devices are engineered to operate under high pressure and corrosive environments, ensuring safety and accuracy in maritime operations.

✓ Military and Defence

In the defense industry, full-service EMS providers produce ruggedized communication equipment and electronic control systems for vehicles. These products are built to endure extreme conditions and meet stringent military standards for reliability and security.

✓ Medical Device

EMS providers in the medical field develop portable diagnostic equipment and patient monitoring systems. These devices require precision manufacturing and compliance with healthcare regulations to ensure patient safety and accurate diagnostics.

✓ Automotive

In the automotive industry, full-service EMS providers manufacture engine control units (ECUs) and in-vehicle networking systems. These components are essential for vehicle performance, safety, and connectivity, requiring high reliability and compliance with automotive standards.

✓ Industrial Automation

For industrial automation, EMS providers create programmable logic controllers (PLCs) and control electronics for industrial robots. These systems enhance manufacturing efficiency and precision, necessitating robust design and durability.

✓ Aerospace and Aviation

In aerospace, full-service EMS providers develop avionics control systems and flight data recorders. These critical components must meet rigorous safety and performance standards to ensure the safety and efficiency of aircraft operations.

✓ Telecommunications

EMS providers in telecommunications produce network routers, switches, and wireless communication modules. These devices are vital for reliable and fast communication networks, requiring high-quality manufacturing and testing.

✓ Oil and Gas

In the oil and gas industry, full-service EMS providers manufacture drilling and exploration sensors and pipeline monitoring systems. These products are designed to operate in hazardous environments, ensuring safety and efficiency in energy extraction and transportation.

✓ Consumer Electronics

For consumer electronics, EMS providers develop smart home devices and wearable gadgets. These products require sleek designs, user-friendly interfaces, and reliable performance to meet consumer expectations.

By offering specialized services tailored to each industry’s requirements, full-service EMS providers like IMS ensure that products are manufactured to the highest standards and optimized for their specific applications.

Choosing the Right Full-Service EMS Partner

Selecting the right electronic manufacturing services (EMS) partner is a crucial decision that impacts every stage of your project. When choosing a full-service EMS provider, it’s essential to ensure they have the expertise, resources, and flexibility to meet your needs from concept to completion. Here’s what to look for in a full-service EMS partner:

- → Comprehensive Capabilities Across All Stages

- End-to-End Expertise: A strong full-service EMS provider should offer support across the entire production lifecycle, from initial design and engineering to material sourcing, assembly, testing, and post-production. This ensures a seamless transition between stages and minimizes the risk of miscommunication.

- Advanced Equipment and Technologies: Look for a partner with access to cutting-edge equipment, such as advanced PCB assembly machinery, precision testing facilities, and design software. These resources improve accuracy and help deliver high-quality results.

- → Industry-Specific Experience

- Understanding of Your Industry Standards: Different industries, such as medical, aerospace, automotive, and consumer electronics, come with unique regulations and requirements. An EMS provider with experience in your industry will understand these standards and know how to meet compliance needs efficiently.

- Adaptability to Complex Requirements: Industries like military, oil and gas, and telecommunications often require specialized materials, ruggedized designs, or strict reliability standards. Make sure your EMS partner has a track record of meeting these complex demands.

- → Commitment to Quality and Compliance

- Certifications and Quality Assurance: Verify that the provider holds relevant certifications, such as ISO 9001 for quality management or ISO 13485 for medical devices, which demonstrate a commitment to maintaining strict quality standards.

- Robust Testing Capabilities: Quality control in EMS goes beyond initial assembly. Look for a partner with a full suite of testing services, including functional, environmental, and in-circuit testing. This ensures every product is rigorously checked for reliability and performance before it reaches the market.

- → Transparent and Collaborative Communication

- Clear Project Management: A reliable EMS partner should provide a dedicated project manager or account manager who keeps you informed at every step, from initial design consultations to final delivery. This single point of contact can streamline communication and simplify the production process.

- Open Feedback Loops: Collaborative EMS providers encourage feedback and proactively involve you in key decisions, such as design adjustments or sourcing options. This level of transparency helps you stay engaged with the process and align the final product with your vision.

- → Scalability and Flexibility

- Capacity to Handle Your Volume: Whether you’re producing a limited batch or scaling up to large-volume production, ensure the EMS provider can adjust their capacity to meet your needs. They should also be able to ramp up production efficiently if demand grows.

- Flexibility for Design Adjustments: Projects evolve, and an ideal EMS partner can adapt to design changes without sacrificing timelines or quality. Look for a provider who offers flexible design-for-manufacturability (DFM) support to accommodate adjustments as needed.

- → Strong Supply Chain and Material Management

- Supplier Network: A full-service EMS provider with established relationships in the supply chain can secure high-quality, cost-effective components quickly, even for specialized parts. This minimizes delays and ensures steady production flow.

- Inventory and Lead Time Management: Ask about the provider’s approach to inventory management and their ability to handle lead times efficiently. An organized, well-managed supply chain can make a big difference in meeting deadlines.

- → Post-Production and Lifecycle Support

- End-of-Life and Repair Services: An ideal EMS partner offers support that extends beyond initial production. Services such as product lifecycle management, repair, and warranty management ensure you’re supported throughout the product’s lifespan.

- Logistics and Distribution: Full-service providers often handle packaging, warehousing, and distribution to ensure your products reach their destinations smoothly. This level of support is especially valuable if you’re shipping to multiple regions or managing high-volume orders.

By choosing an EMS partner with these capabilities, you’re setting your project up for success from the start. A full-service provider like IMS not only streamlines the production process but also adds value at each stage, ensuring a high-quality final product that meets your industry’s standards and your customers’ expectations.

Why Full-Service EMS is Essential for Today’s Manufacturers

Partnering with a full-service electronic manufacturing provider offers more than just convenience—it delivers a streamlined, high-quality approach that supports every stage of product development.

By choosing a full-service EMS partner like IMS, you gain a team of experts dedicated to optimizing design, ensuring supply chain efficiency, and delivering precision assembly backed by rigorous testing and post-production support. This level of collaboration allows you to focus on what matters most: innovation and growth.

Ready to unlock new possibilities? Contact IMS today to discover how our contract electronic manufacturing services can transform your business.