Almost every electronic gadget you use—from your smartphone to your home appliances—owes its existence to Electronic Manufacturing Services (EMS). But what is electronic manufacturing services? And why is it so essential to the devices we use daily?

This guide explains the meaning of electronic manufacturing services in simple terms and walks you through some of the key services EMS providers offer. From assembling circuit boards to integrating entire systems, EMS partners like IMS Electronics Manufacturing are behind the scenes, turning innovative ideas into functional technology.

What Is Electronic Manufacturing Services?

Electronic Manufacturing Services (EMS) refer to a comprehensive range of services that manufacturers provide to bring electronic products to life. The meaning of electronic manufacturing services goes beyond just putting together circuit boards. It includes everything from designing prototypes and sourcing components to assembly, testing, and ensuring a finished product is ready for market.

Instead of companies manufacturing their own electronics from scratch, many rely on contract EMS providers to handle production. This partnership saves time, cuts costs, and allows companies to focus on their core business—innovation.

Main Services Offered by EMS Providers

EMS covers a wide range of specialized services supporting each stage of a product’s development and manufacturing process. Below, we explore the main services provided by companies like IMS Electronics Manufacturing.

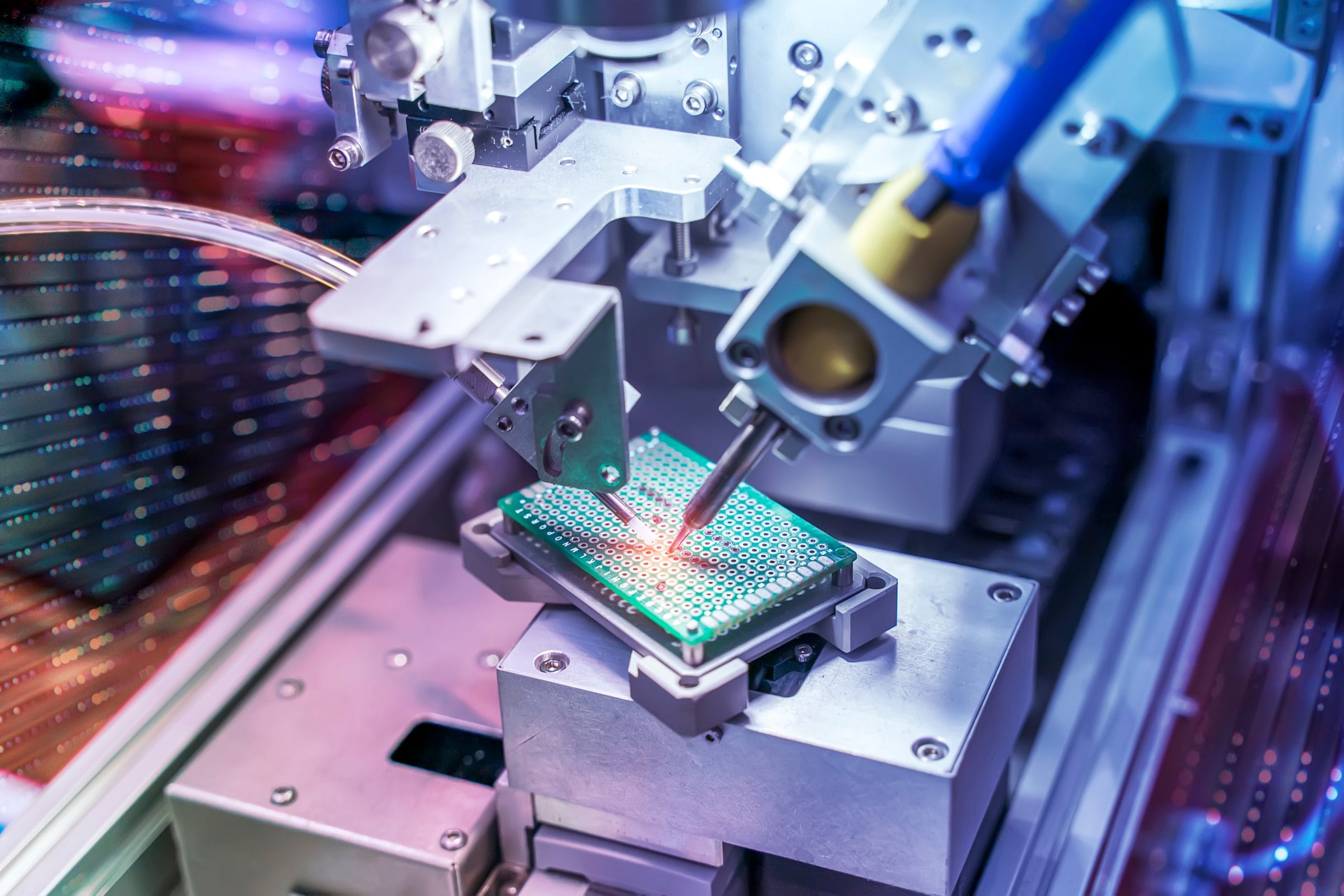

1. Circuit Board Assembly

Circuit board assembly is the process of attaching components—like resistors, capacitors, and integrated circuits—to a printed circuit board (PCB). The PCB is the “brain” that allows all the parts of an electronic device to work together. Without a properly assembled circuit board, there’s no smartphone, laptop, or home gadget.

- How We Do It: IMS uses a combination of Surface Mount Technology (SMT), where components are placed directly onto the PCB, and Through-Hole Technology (THT), which threads components through the board for added durability. SMT works well for small, compact designs, while THT adds strength where it matters most.

- Benefits for Clients: By outsourcing circuit board assembly to an experienced EMS partner like IMS, companies ensure quality and consistency in every board, reducing errors and boosting product reliability.

2. Box Build Assembly

Box build assembly goes beyond assembling circuit boards. It involves integrating these boards into complete, functional products, including enclosures, cabling, and sub-assemblies.

- How We Do It: IMS handles everything from simple sub-assemblies to complete system integration, including rugged enclosures to protect components. This makes our products suitable for challenging environments, like oil rigs, military applications, or avionics.

- Benefits for Clients: Full system assembly ensures that all parts fit seamlessly, resulting in faster production, fewer errors, and a product built precisely to customer specifications.

3. Custom Cable Assembly

Cable assemblies are essential in almost every electronic system. They provide reliable connectivity, ensuring that every part of a product functions as intended.

- How We Do It: IMS produces custom cable assemblies tailored to each project’s needs. Whether it’s a simple wire harness or a multi-conductor cable, we ensure every connection is built to high standards using both automated and manual techniques.

- Benefits for Clients: By leveraging custom cable assembly, businesses get dependable, high-quality connectivity solutions that integrate perfectly into their products, improving performance.

4. Mechanical Assembly

Mechanical assembly focuses on connecting various physical components together to build more robust sub-systems.

- How We Do It: IMS specializes in integrating various mechanical components, such as fasteners, brackets, and connectors, to provide full or partial assemblies. Mechanical assembly ensures that these parts fit together seamlessly and are ready to integrate into larger systems.

- Benefits for Clients: Outsourcing mechanical assembly means clients receive sub-systems that are fully tested for both fit and functionality, reducing the time and complexity involved in the final product integration.

5. Coating and Encapsulation

a. Protective Coating (Conformal Coating)

Protective coating, also known as conformal coating, is a thin layer of specialized material applied over a PCB to safeguard it from harsh environmental conditions, such as moisture, dust, or chemical contaminants.

- How We Do It: IMS uses automated conformal coating systems to precisely apply a protective coating layer over circuit boards. We use high-quality silicone and UV-cure acrylic materials that are designed to withstand the challenges posed by different operating environments.

- Benefits for Clients: Protective coatings help prolong the life of electronic products, particularly those used in environments prone to dust, moisture, and other contaminants. It ultimately boosts the reliability and performance of products for our clients.

b. Encapsulation (Potting)

Encapsulation, often referred to as potting, involves surrounding electronic components with a thick layer of resin to provide additional protection from physical damage, shock, and environmental exposure.

- How We Do It: IMS offers potting services using a variety of materials, such as silicone, epoxy, and urethane, to ensure robust protection. Potting shields components from vibration, extreme temperatures, and physical impact.

- Benefits for Clients: Encapsulation helps to reinforce and protect sensitive electronic components, extending their lifespan and ensuring stable operation even in challenging conditions.

Why Should You Consider an EMS Partner for Your Next Project?

✓ Scalability

EMS providers offer the flexibility to scale production up or down based on demand—ideal for new product launches or changes in the market.

✓ Expertise and Focus

By outsourcing production to an EMS provider, businesses can focus on their core strengths like innovation, while EMS handles the complexities of manufacturing.

✓ Quality and Reliability

EMS providers like IMS follow strict quality control processes, ensuring high standards are met in every project. Certifications like ISO 9001 back up our commitment to quality.

✓ Cost-Efficiency

By working with an EMS provider, companies avoid the overhead of running their own production facilities while also benefiting from efficient supply chain management.

✓ Speed to Market

EMS partners have the infrastructure and know-how to get your product to market faster. From prototyping to advanced manufacturing capabilities, they keep the timeline efficient.

Idea to Implementation: Let IMS Lead the Way

If you’ve ever wondered what is electronic manufacturing services? the answer lies in these comprehensive solutions that power innovative projects from start to finish. Whether it’s precise circuit board assembly, box build integration, or custom cable manufacturing, EMS partners like IMS Electronics Manufacturing have the expertise to bring your ideas to life.

Explore what’s possible! If you’re ready to bring your next big idea to life, let IMS be your innovation partner. Contact us today to discover how our EMS solutions can take your project from concept to reality.