What keeps the oil and gas industry running smoothly? Beyond the visible operations of rigs, pipelines, and refineries lies a critical enabler—technology. At the core of this technology is Electronic Manufacturing Services (EMS), which transforms advanced electronic components into field-ready tools built to endure the toughest environments.

EMS providers play an essential role by designing and manufacturing sensors, monitoring systems, and safety tools that keep everything running smoothly, safely, and efficiently. They transform advanced electronic components into rugged, field-ready tools that make a difference where and when it counts. But how exactly do electronic manufacturing services for oil and gas power these advancements, and why is it indispensable to the future of O&G?

Why EMS Matters in Oil & Gas Operations

The oil and gas sector operates under incredibly challenging conditions and climates where precision and reliability are absolute necessities. Contract EMS partners step up to meet these challenges, providing the technology needed to operate effectively under harsh conditions while adhering to strict regulatory standards.

Tough Tech for Tough Conditions

The oil and gas industry pushes equipment to its limits—drilling in deep-sea environments, enduring extreme heat in desert rigs, or braving freezing temperatures in remote extraction zones. EMS partners design and manufacture components that meet these challenges head-on. Whether it’s drilling sensors capable of withstanding intense pressure or monitoring tools that function flawlessly under fluctuating temperatures, EMS technology is built to be as rugged as the environment it serves.

Compliance Means Safety, Not Just Rules

With operations often conducted in volatile environments, stringent regulations demand high-quality equipment. EMS providers help meet certifications like ATEX for explosive environments, ensuring that every component meets strict safety and reliability standards. This level of compliance is critical for reducing risks and protecting both personnel and the environment.

Unmatched Precision Drives Efficiency

When drilling far below the Earth’s surface or moving fuel through pipelines that stretch for thousands of miles, precision is critical. EMS partners deliver advanced engineering, from high-tech sensors that collect real-time data to automation technologies that enhance process efficiency. This level of precision minimizes downtime, optimizes performance, and significantly reduces operational risks, ensuring smoother, safer operations.

EMS Services That Propel Oil & Gas

Electronic manufacturing services for oil and gas offer a suite of advanced technical solutions that keep the oil and gas industry moving forward. Here’s how:

1. Custom Design and Rapid Prototyping

No two oil and gas projects are alike. EMS partners collaborate closely with clients to design custom solutions that fit these specific requirements. Rapid prototyping speeds up the development process, turning concepts into working models quickly, so projects stay on track.

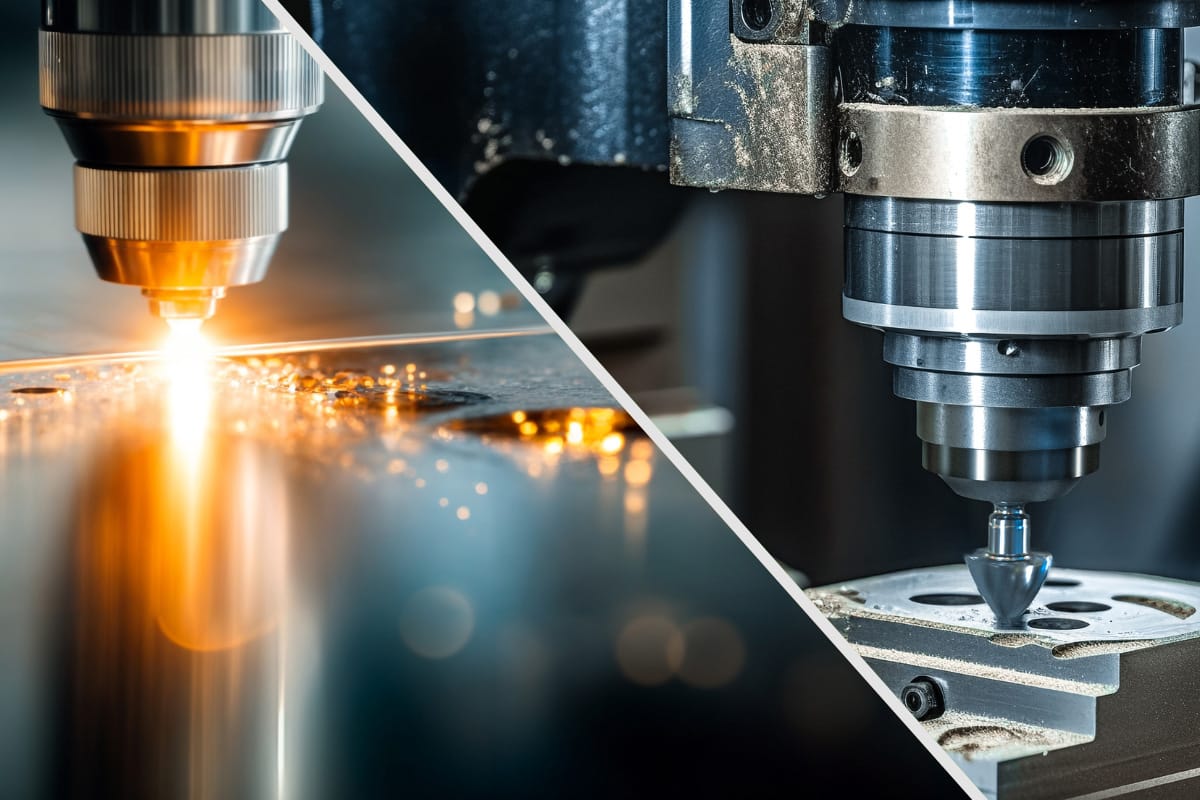

2. Precision Manufacturing and Assembly

Whether it’s lightweight, compact sensors, or durable safety systems, precision manufacturing is essential. EMS providers utilize advanced manufacturing techniques—like Surface Mount Technology (SMT) for efficiency and Through-Hole Technology (THT) for durability—to create components that perform reliably under demanding conditions.

3. Testing and Quality Assurance

In the high-stakes oil and gas sector, reliability is everything. EMS partners use extensive testing protocols—from burn-in testing to environmental stress screening—to ensure that each component can perform under extreme conditions, reducing the risk of failure in the field.

4. Supply Chain Management and Scalability

The O&G industry often operates in remote and challenging environments, where the logistics of obtaining the right materials can be complex. EMS providers help manage the complexities of procurement, ensuring that materials arrive when needed, reducing downtime, and keeping operations running smoothly.

5. Lifecycle Management and Ongoing Support

Components used in oil and gas operations need to be reliable for years. EMS partners provide long-term support, including maintenance, upgrades, and redesigns, ensuring that electronic systems continue to meet industry demands over time without requiring costly replacements.

Pioneering Innovations in Oil & Gas Technology

The role of EMS in the oil and gas industry extends far beyond the production of electronic components. Manufacturers like IMS Electronics actively drive innovation, helping oil and gas companies push the boundaries of what’s possible. Some areas where electronic manufacturing services for oil and gas are making a substantial impact:

✓ Smarter Drilling Sensors and Exploration Tools

Modern drilling relies heavily on advanced sensors that deliver real-time data. EMS providers enhance these sensors by integrating the latest technologies, allowing for more detailed data collection, remote operation, and real-time adjustments. The result? Drilling becomes smarter, faster, and safer, leading to fewer errors and less waste.

✓ Intelligent Monitoring of Pipelines

Pipeline health is a critical aspect of O&G operations. Leaks, corrosion, or damage can have serious consequences. EMS solutions integrate IoT (Internet of Things) technology and data-driven analytics into monitoring systems, providing unparalleled pipeline oversight. These smart solutions offer continuous, real-time insights into pipeline integrity. They can identify problems before they escalate and keep environmental and operational risks in check.

✓ Enhanced Safety System Controls

EMS providers are making significant strides by developing technologies that support operational safety. This includes automated safety systems such as emergency shutdown mechanisms, pressure management systems, and predictive diagnostics for equipment health. By making safety systems smarter, EMS partners help protect both people and infrastructure.

✓ Innovations in Sustainability

Sustainability is a growing priority in oil and gas. EMS partners contribute by designing eco-friendly technologies and incorporating greener practices into manufacturing processes. From minimizing energy use to choosing materials with lower environmental impact, a knowledgeable EMS partner will help their O&G clients move toward a more sustainable future.

✓ Scalable, Modular Solutions

Flexibility is a must in oil and gas operations. EMS partners develop modular systems that can be scaled and customized to fit changing project needs, allowing for efficient technology integration and faster market adaptation.

Addressing O&G Industry Challenges

The oil and gas industry is no stranger to obstacles. Harsh environments, regulatory hurdles, and complex logistical needs are part of everyday operations. That’s where a strong EMS partner comes in, offering targeted solutions to these challenges through expert services. Here’s how we help tackle these challenges:

1. Seamless Integration

Whether it’s drilling equipment or monitoring systems, seamless integration is vital to the productivity of oil and gas operations. An oil and gas electronic manufacturing partner can design and assemble components that work effortlessly together, reducing the burden on engineering teams.

2. Resilient Supply Chains

Working in remote locations is a logistical challenge for oil and gas companies—whether on an offshore platform or a remote land rig. EMS providers help build resilient supply chains by managing complex procurement processes, establishing global networks, and leveraging strategic partnerships. The goal is to ensure that materials and components are available when needed, reducing the risk of costly downtimes and delays.

3. Meeting Regulatory Standards

Oil and gas operations are heavily regulated to ensure safety and minimize environmental impact. EMS partners help companies navigate these regulations by providing components that comply with industry standards. By integrating compliance into the design and production stages, EMS providers allow O&G companies to focus on their core tasks without worrying about meeting safety benchmarks.

4. Staying Ahead With Technology

The push for smarter, automated systems requires continuous innovation. Reputable EMS partners invest in research and capabilities to help oil and gas companies adopt the latest technologies, keeping them competitive in an evolving industry.

The Future of EMS in Oil & Gas: A Look Ahead

The oil and gas industry is undergoing a transformative era. As the sector shifts towards greater efficiency, smart automation, and sustainability, Electronic Manufacturing Service providers are helping lead the charge.

→ Digital Twins for Smarter Maintenance

Think of a digital twin as a virtual version of your drilling rig. EMS is making this a reality by crafting sensors that provide real-time data, enabling predictive maintenance. It means fewer surprise breakdowns and more planned efficiency.

→ Robotics and Remote Exploration

Picture a remotely operated vehicle inspecting a deep-sea pipeline. EMS is behind the tech that powers these robots—helping oil and gas companies explore extreme environments safely and efficiently, all without putting human workers at risk.

→ Hybrid Power for Greener Platforms

Offshore rigs are going green by incorporating solar panels and wind turbines alongside conventional power systems. EMS supports this shift by building hybrid power solutions, helping reduce carbon footprints while ensuring uninterrupted energy flow.

→ Edge Computing for Real-Time Decisions

Imagine an offshore platform analyzing equipment data instantly, on-site. EMS is advancing rugged edge computing devices that allow real-time decision-making without relying on distant data centers—crucial for maintaining efficiency in remote locations.

Powering the Future of Oil & Gas

From drilling sensors that deliver precise data to smart monitoring systems that prevent costly setbacks, EMS solutions are reshaping the way we approach energy production. IMS Electronics Manufacturing is at the forefront of this transformation, providing durable, advanced electronics that drive the oil and gas sector forward.

Harness the power of EMS to elevate your O&G operations. Reach out to IMS today and discover how we can develop tailored solutions for your unique challenges. It’s time to advance your technology, enhance safety, boost productivity, and lead in your field.