As 2024 comes to a close, IMS reflects on a year of transformation, innovation, and success. This year marked significant milestones, including the unveiling of a redesigned logo that embodies the company’s mission and vision, the implementation of new initiatives, and remarkable progress toward future goals. Celebrations and achievements from the company’s 20th anniversary event highlight the collective efforts that have propelled IMS forward.

Redesigned Logo

In 2024, IMS unveiled a redesigned logo as part of its rebranding effort to reflect its core mission and vision. This new identity symbolizes IMS’s growth and commitment to being the premier partner and provider of Electronics Manufacturing Services. The logo features a dynamic blue globe, representing IMS’s global reach, with electronic circuits encircling the globe, highlighting the company’s expertise and emphasizing that technology connects us around the world.

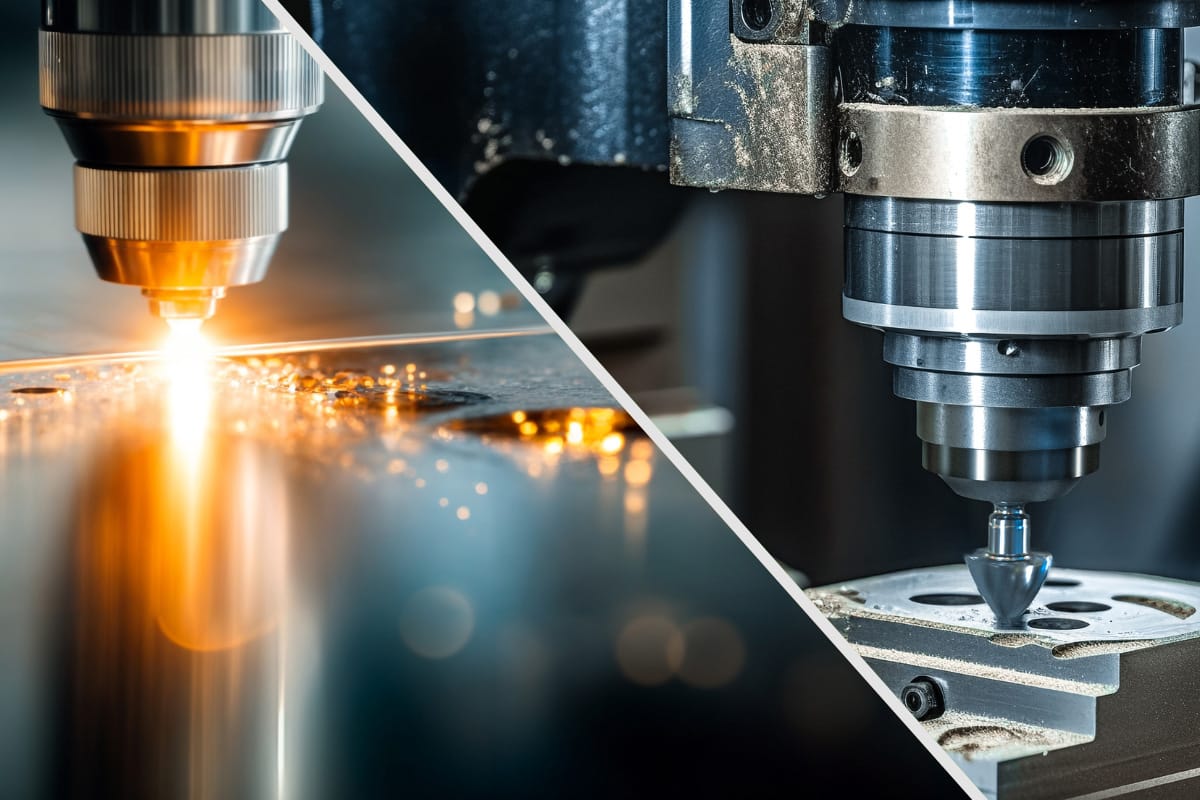

IMS Metal Fabrication Services: Supporting Full Box Build Assemblies and Metal Work

At IMS, we offer a comprehensive range of Metal Fabrication services designed to meet the diverse needs of our customers. Whether you require full box build assemblies or specialized metal work, our expertise and advanced technology ensure precise and high-quality results. Our sheet metal fabrication services cater to everything from simple parts to highly detailed components.

Our capabilities include advanced metal forming, laser cutting, punching, and various welding techniques such as MIG, TIG, and spot welding. We work with a wide array of materials, including aluminum, copper, stainless steel, cold-roll, and satin coat steel, ensuring that each project is executed with precision.

We emphasize efficiency by minimizing waste and maximizing material usage, keeping production costs low while maintaining exceptional quality. Our team is dedicated to delivering durable, functional metal solutions tailored to your specific needs—whether you require complete assemblies or custom metal components.

IMS’s Metal Fabrication services are ideal for both large-scale projects and smaller, specialized orders, offering the flexibility and precision needed to support your business’s unique requirements.

For more detailed information on the types of metals we work with, the scope of our services, and how we support sustainability, visit our sheet metal fabrication and forming page.

Enhanced Website and Social Media Presence

In addition, IMS launched a redesigned website that offers a more informative and interactive user experience. Featuring videos and photos of the staff and production facility, the site showcases IMS’s capabilities in electronics and metal shops. It also hosts weekly and monthly blogs on contract electronics manufacturing, covering topics like production processes and the benefits of partnering with IMS, reinforcing the company’s industry leadership.

IMS has expanded its social media presence in 2024, establishing a stronger presence on platforms such as LinkedIn, Facebook, and Google Ads. The company has been posting a variety of informative and thought-provoking articles that highlight IMS’s service offerings, industry processes, and manufacturing standards. By sharing valuable insights and updates, IMS aims to foster deeper connections with current and potential customers while reinforcing its commitment to excellence in the industry.

Looking ahead, IMS will expand its digital footprint with a YouTube presence in 2025.

IMS will share engaging behind-the-scenes content, including visuals of product development, tech spotlights on advanced equipment, leadership insights and more.

Industry Engagement and Operational Excellence

IMS further strengthened its industry presence in 2024 by participating in the Vancouver and Calgary Eptech Electronics shows. These events provided an opportunity to showcase both IMS Electronics and IMS Metal services, highlighting the company’s comprehensive contract manufacturing capabilities. The shows allowed IMS to forge valuable connections, promote its services, and demonstrate the expertise of its talented and knowledgeable staff, emphasizing the skills they bring to every customer’s product build.

In February 2024, a group of IMS representatives attended the Apex Show in Anaheim, California, with the goal of evaluating the latest electronics manufacturing equipment and software. This initiative reflects IMS’s commitment to staying at the forefront of technology and expanding its service offerings to better meet the evolving needs of its customers.

IMS continued its focus on Lean Manufacturing throughout 2024, implementing strategies across all areas of the company to eliminate waste and enhance efficiency and productivity.

Additionally, senior members of IMS’s accounting team traveled to Atlanta for a weeklong conference to learn about new features and enhancements of the company’s ERP system, ensuring the full utilization of its capabilities.

In February 2024, IMS also successfully achieved recertification of ISO 9001:2015, reinforcing its ongoing commitment to maintaining the highest quality standards.

Implementation of New Initiatives

IMS has continued to lead in the industry by embracing cutting-edge technologies and sustainable practices. Highlights of 2024 include:

Advancing Automation and AI: IMS has integrated advanced automation and AI algorithms to optimize production processes, improve quality control, and predict maintenance needs.

Sustainability Commitments: The Company continues to incorporate eco-friendly manufacturing and recycling processes, reinforcing its dedication to environmental responsibility.

Enhanced Customization and Flexibility: IMS’s manufacturing systems have been upgraded to meet evolving customer demands, delivering bespoke products with rapid turnaround times.

Cybersecurity Measures: As the industry grows more interconnected, IMS has strengthened its focus on safeguarding operations and intellectual property.

Company’s Progress and Future Plan

In 2024, IMS celebrated significant growth and reaffirmed its commitment to innovation. The company now operates with over 120 team members in a state-of-the-art 77,000-square-foot facility, a testament to its two-decade-long journey from a small start-up. Looking ahead, IMS plans to:

● Further integrate machine learning to drive predictive analytics and operational excellence.

● Expand its global reach while maintaining its focus on quality and customer satisfaction.

Celebrating 20 Years of Excellence

A significant milestone in 2024 was IMS’s 20th anniversary celebration. Since its inception, IMS has empowered over 250 customers, providing comprehensive support across procurement, production, assembly, testing, and sheet metal fabrication. On September 5, IMS hosted a memorable event for over 250 guests. The celebration featured BBQ delights, a chocolate fountain, giveaways, and facility tours led by Dave, Brenden, Caitlyn, Martina, Neil, and Nikhil, showcasing IMS’s diverse services and cutting-edge machinery. The event was a testament to IMS’s journey and the partnerships that have fueled its growth.