If you’ve ever worked with a manufacturer who took your designs, disappeared into silence, and then returned weeks later with unexpected costs, delays, or quality issues—you’ve experienced the “black box.”

Poor communication in manufacturing isn’t just frustrating. It’s expensive. Projects stall. Budgets overrun. Trust erodes.

But it doesn’t have to be that way. When you find an EMS partner that understands the meaning of true partnership, it becomes clear: good communication is as critical to success as technical capability. The best EMS providers offer visibility, transparency, and collaboration throughout the project lifecycle.

TL;DR

- Poor communication in manufacturing creates “black box” projects leading to delays, hidden costs, and frustrated customers.

- A good EMS partner will provide milestone reporting, accessible contacts, real-time visibility, and open pricing communication.

- Best practices include setting expectations upfront, scheduling check-ins, defining escalation paths, and reviewing performance post-project.

- IMS eliminates the “black box” with approachable, responsive communication, direct access to decision-makers, and integrated updates across electronics and sheet metal teams.

Why Communication Often Breaks Down in EMS

Many companies come to us after experiencing communication headaches with previous vendors.

Common issues include:

⚠️ Information silos: Engineering, production, and customer service teams aren’t aligned, leaving customers with inconsistent or incomplete updates.

⚠️ Technical complexity: Customers are flooded with jargon instead of clear, actionable information.

⚠️ Volume focus vs. relationship focus: Some manufacturers prioritize throughput at the expense of personal communication.

⚠️ Lack of proactive updates: Instead of hearing about issues early, customers only learn about problems once deadlines slip.

The impact is real: misaligned expectations, production delays, quality rework, and stressed relationships. For growing companies, poor communication from an electronics manufacturer can mean missed market windows or lost contracts.

What Good EMS Communication Looks Like

If you’re evaluating electronic manufacturing services, here’s what to look for in a communication-focused partner:

1. Regular project updates

Weekly or milestone-based reporting keeps everyone on the same page, eliminating last-minute surprises.

2. Proactive issue management

Instead of waiting for problems to escalate, strong EMS providers flag risks early and suggest practical solutions.

3. Clear documentation

From design changes to approvals, every adjustment should be documented and accessible—reducing confusion and rework.

4. Accessible points of contact

You shouldn’t have to chase answers. A responsive account manager or project lead should always be within reach.

5. Transparent pricing and timelines

Clarity upfront about costs, schedules, and scope changes builds trust and helps you budget accurately.

6. Real-time visibility

Dashboards, shared tools, or even simple progress summaries give you confidence that your project is moving as planned.

When these practices are in place, the “black box” disappears. Instead, you gain a collaborative experience where progress and expectations are always visible.

Learn more: What to Look for When Choosing Manufacturing Companies in Canada

Communication Best Practices for Your Projects

Here’s how to set communication expectations and keep them strong throughout your electronics manufacturing projects:

💡 Set expectations early: Agree on communication frequency, preferred channels, and reporting formats.

💡 Schedule regular check-ins: Standing updates (weekly or milestone-based) prevent drift and maintain accountability.

💡 Define escalation paths: Know who to call if issues arise, and set clear response times.

💡 Document design changes: Even small adjustments should be recorded to avoid miscommunication.

💡 Share quality results: Testing and inspection results should be reported openly, not hidden until the end.

💡 Review post-project: A debrief helps both sides improve processes and strengthens the partnership long term.

These best practices apply across industries—from medical devices to industrial controls—and ensure your electronics manufacturing partnership supports growth instead of creating barriers.

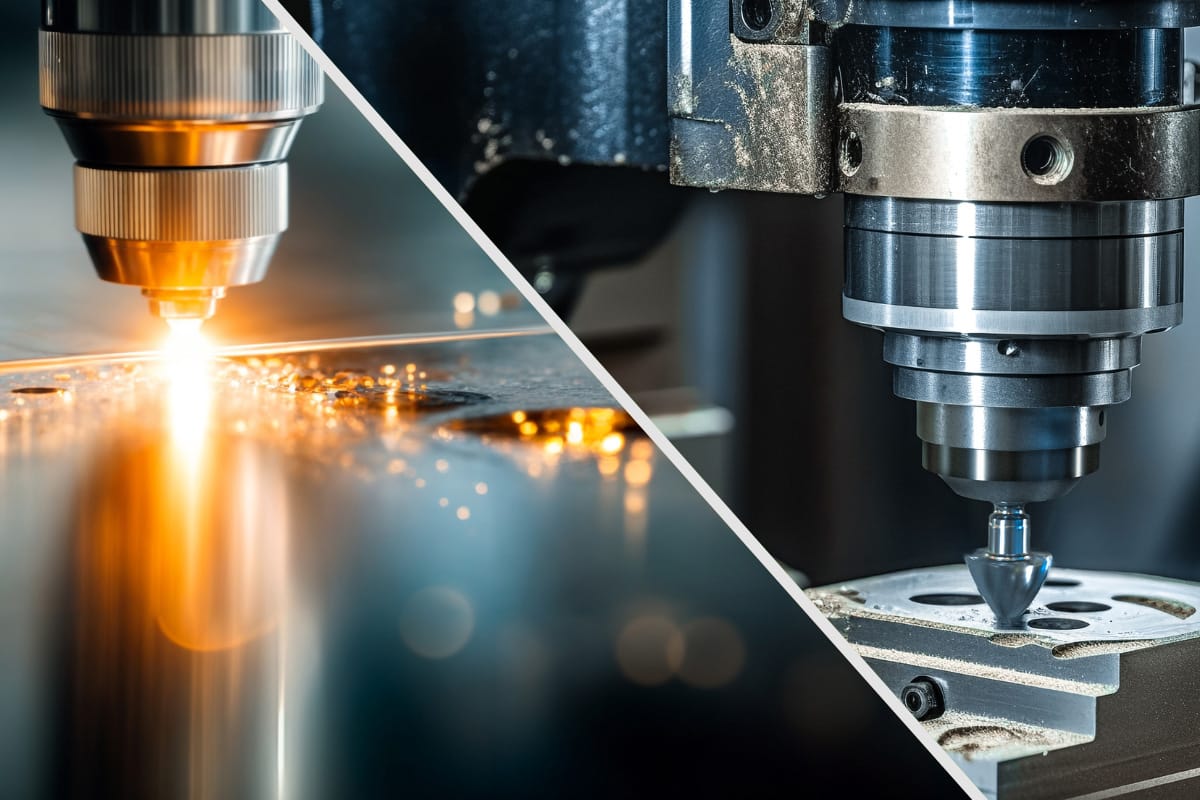

The IMS Communication Advantage

At IMS, we believe good manufacturing partnerships are built on people, not just processes.

Customers consistently tell us they appreciate our:

✓ Friendly, approachable, responsive culture

✓ Direct access to decision-makers and technical teams

✓ Integrated communication between electronics and sheet metal teams

✓ Canadian time zone advantage, making collaboration seamless for North American customers

✓ Personal relationship focus instead of corporate bureaucracy

✓ Proactive communication style that ensures no surprises

When you work with IMS, you’re never left in the dark. You know where your project stands, what’s next, and who to call. That’s what an EMS partnership should be: a true collaboration where transparency drives success.

Partner With an EMS Provider That Keeps You Informed

Communication makes or breaks electronics manufacturing projects. You deserve a partner who values transparency as much as quality.

Contact us today to talk about your project. We’ll show you what responsive communication feels like from day one.

With IMS, you get an EMS partner who keeps you informed and confident at every project stage.