Box build assembly is the stage where a printed circuit board becomes a complete, production-ready system. A populated PCB provides electrical functionality, but it does not yet function as a deployable product.

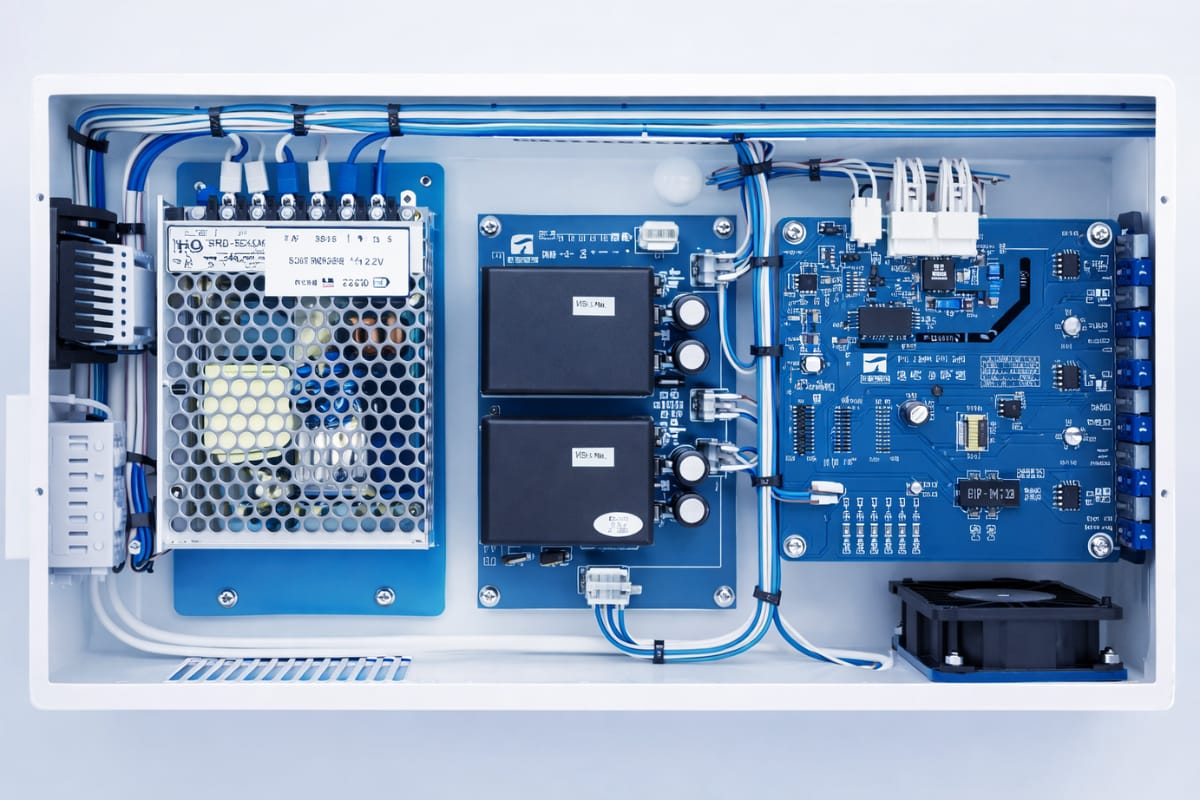

Once the board is installed into an enclosure and integrated with mechanical components, wiring, power systems, firmware, and system-level testing, it transitions into hardware that can operate in real-world conditions.

For manufacturers in industrial, medical, aerospace, and telecommunications markets, this stage determines whether a design performs reliably outside the lab.

What Box Build Assembly Includes

Box build assembly extends beyond placing a PCB into an enclosure. It requires coordination across mechanical fabrication, electrical integration, firmware configuration, and validation.

Tolerances between the enclosure, mounting hardware, and circuit boards must align precisely. Cable routing must support airflow and serviceability. Power distribution must remain stable under operational load. Each decision made during integration affects long-term reliability.

Depending on system complexity, box build may involve:

- Multi-board integration within a single enclosure

- Custom sheet metal or structural fabrication

- Firmware loading and revision control

- Functional and environmental testing

In higher-complexity systems, this stage determines whether a product can scale cleanly from prototype to production.

The Structural Layers of Box Build Assembly

Box build assembly is best understood as a coordinated process across three layers: mechanical integration, electrical integration, and system configuration.

Mechanical Integration

Mechanical integration provides structural integrity, thermal management, and environmental protection. This may include custom or off-the-shelf enclosures, mounting brackets, heat sinks, EMI shielding, and connector interfaces.

Tolerance control is critical at this stage. Small dimensional variations can affect alignment, airflow, and cable routing. Over time, those issues can translate into mechanical stress or premature failures in the field.

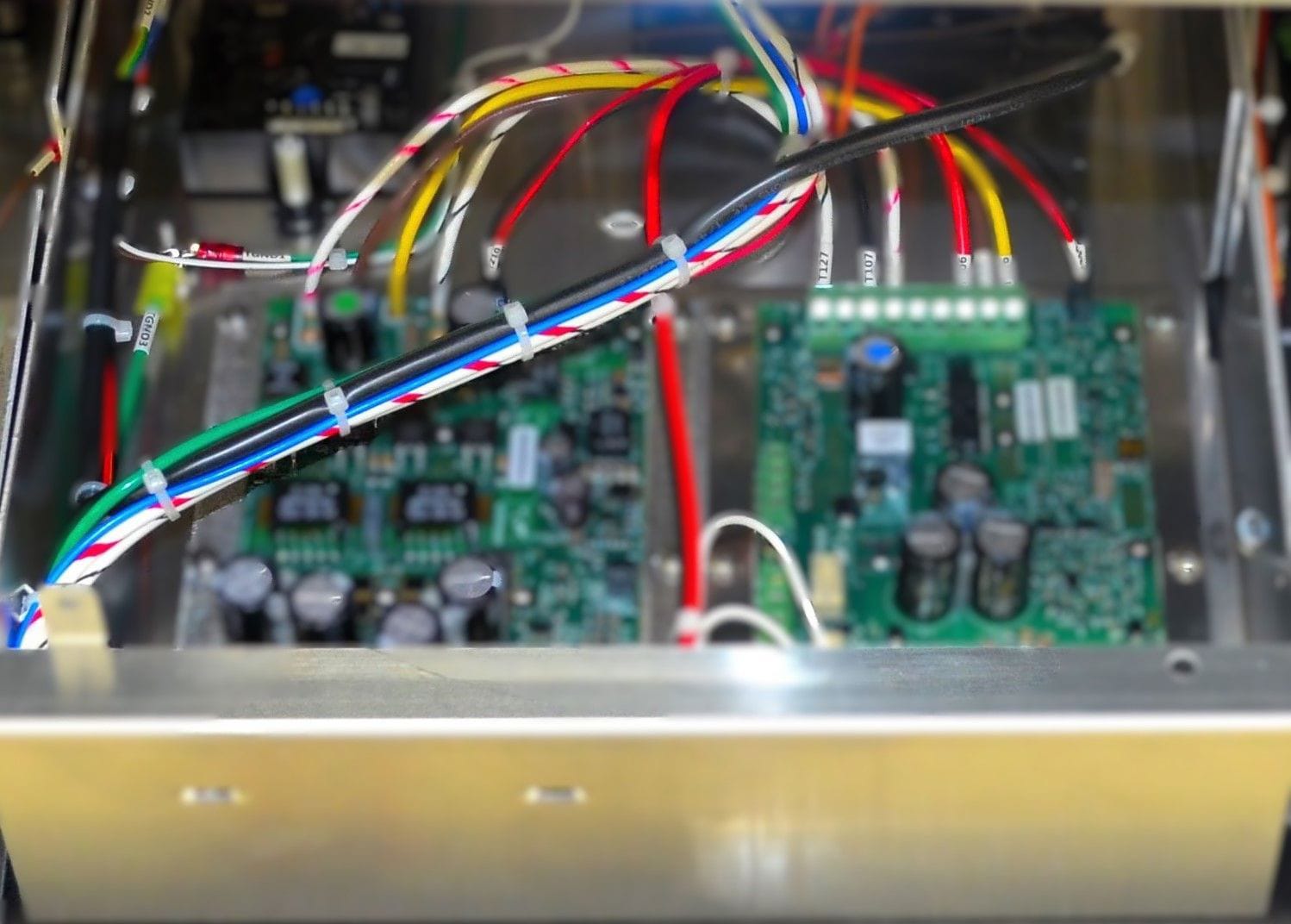

Proper cable routing and strain relief reduce congestion and long-term failure risk

Electrical Integration

Electrical integration connects and organizes all power and signal pathways inside the enclosure. This typically includes PCB mounting and grounding, custom cable assemblies, wire harness routing, power supply installation, and connector termination.

Cable routing is often underestimated. Congestion, inadequate strain relief, or poor spacing can lead to heat buildup, signal interference, or serviceability problems later on.

System Configuration and Testing

Beyond physical assembly, box build also includes configuration and validation. Firmware is loaded, calibration procedures are completed, and functional testing confirms expected behaviour.

At this stage, the product transitions from an assembled unit into a verified operating system. Documentation, labelling, and traceability support quality control and regulatory requirements.

The Box Build Assembly Process

A disciplined box build assembly process follows a structured workflow designed to reduce integration risk.

Design for Manufacturability Review

Before production begins, engineering teams review the design to identify mechanical, electrical, and compliance risks. This includes tolerance stack-ups, thermal requirements, service access, and regulatory constraints.

Resolving these issues early reduces rework and protects production timelines.

Supply Chain Coordination

Box build assembly often involves components from multiple suppliers, including enclosure fabricators, power supply vendors, and cable harness providers. Coordinated sourcing keeps revision levels, dimensions, and delivery schedules aligned.

Without centralized oversight, mismatches between components can delay assembly or introduce integration issues.

Kitting and Sub-Assembly Preparation

Before integration starts, materials are staged and verified. Structured kitting confirms correct revisions, complete component availability, and traceable part identification.

Where applicable, sub-assemblies such as harnesses or mechanical modules are prepared in advance. This approach reduces congestion during final assembly and improves inspection consistency.

Mechanical and Electrical Integration

During final integration, populated PCBs are installed into enclosures. Harnesses are routed and secured. Power systems and structural components are mounted and aligned.

Precision at this step affects grounding integrity, airflow, thermal performance, and long-term serviceability.

Firmware Loading and System Validation

Firmware is flashed, and configuration settings are verified. Hardware and software revisions must align exactly to prevent downstream troubleshooting issues.

Functional testing confirms that mechanical and electrical systems operate together under expected conditions. Environmental or burn-in testing may be performed when required.

Common Challenges in Box Build Assembly

Box build assembly introduces complexity that extends beyond PCB population. Mechanical, electrical, thermal, and supply chain variables intersect within a confined enclosure.

Tolerance Stack-Ups

Dimensional variation across enclosures, brackets, and circuit boards can accumulate. Even minor inconsistencies may result in misaligned connectors, mechanical strain, or inconsistent panel fitment.

Cable Routing Constraints

As systems become more compact, internal space becomes limited. Dense harness routing can restrict airflow, place strain on connectors, and reduce service accessibility.

Thermal Management

Enclosed systems must dissipate heat reliably. Poor airflow design or cable blockage can elevate internal temperatures and reduce component lifespan. Thermal performance must be validated during integration rather than assumed.

Scaling to Production

A configuration that performs well in a prototype run may not scale cleanly. Assembly time, inspection throughput, and documentation control become more critical as volumes increase.

Box Build vs. PCB Assembly

PCB assembly focuses on mounting and soldering electronic components onto a printed circuit board. It ensures electrical functionality at the board level but does not address enclosure integration, power distribution, or system validation.

Box build assembly extends beyond the PCB to include:

- Mechanical enclosure integration

- Cable harness installation and routing

- Power supply mounting and grounding

- Firmware configuration

- System-level testing and verification

While PCB assembly confirms that a board functions independently, box build assembly validates that the complete product operates as an integrated system.

For a detailed breakdown of how these processes differ, read our guide to Box Build vs. PCB Assembly.

When Should You Use Box Build Services?

Box build becomes essential when a product moves beyond board-level functionality and requires coordinated mechanical, electrical, and system-level integration.

It is typically the right approach when:

- The product requires custom enclosure fabrication or structural integration

- Multiple PCBs or sub-assemblies must operate within a single housing

- Firmware configuration and version control are part of production

- Compliance standards demand full system validation and traceability

- Production volumes are expected to increase beyond prototype levels

In these scenarios, integration is not optional. It determines how reliably the product can be manufactured, validated, and supported over time.

Industries Where Box Build Is Critical

Industries that frequently rely on box build assembly include:

- Medical device manufacturers

- Industrial automation and control systems

- Aerospace and defence platforms

- Telecommunications infrastructure

- Power and energy equipment

In these sectors, system reliability, documentation control, and production consistency are non-negotiable. Box build assembly ensures that mechanical and electrical systems are validated together before deployment.

Why Integrated Box Build Reduces Risk

Separating PCB assembly, enclosure fabrication, and final system integration across multiple vendors increases coordination overhead and weakens accountability.

When issues surface, responsibility fragments quickly. Revision updates must move across organizations, tolerances stack without shared ownership, and integration problems often appear late, when changes are harder and more expensive to correct.

An integrated box build model keeps mechanical, electrical, and system-level decisions within a single workflow. Design changes, sourcing decisions, and production constraints remain visible across teams instead of being managed in isolation.

Main outcomes of this approach include:

- Single-source accountability for design changes and production outcomes

- Controlled revision alignment across mechanical and electrical components

- Tighter coordination between fabrication and final assembly tolerances

- Fewer freight transfers between vendors

- Earlier identification and resolution of integration issues

- Consistent documentation and traceability

When engineering, sourcing, fabrication, assembly, and testing operate within one coordinated system, integration risks surface earlier and remain easier to manage. Over time, this alignment improves production stability, reduces rework, and supports scalable manufacturing.

Integrated Box Build Assembly at IMS

IMS manages box build assembly as a system integration discipline rather than a downstream extension of PCB assembly. Mechanical, electrical, and software considerations are addressed together instead of being handed off between stages.

Integration starts during design review. Mechanical tolerances, enclosure fabrication methods, wiring architecture, and firmware requirements are evaluated as a single system to limit late-stage adjustments during production.

IMS engineering and production teams collaborating during box build integration

Box build programs are structured around:

- Early design-for-manufacturability collaboration

- Coordination between precision sheet metal fabrication and PCB integration

- Revision control across electrical and mechanical components

- Controlled kitting and material traceability

- Repeatable production workflows that support volume scaling

- System-level validation before shipment

Keeping engineering, sourcing, fabrication, assembly, and testing within one coordinated framework reduces integration variability and improves production consistency.

This structure supports both prototype development and ongoing production.

Frequently Asked Questions

PCB assembly focuses on mounting and soldering components onto a printed circuit board. Box build assembly extends beyond the board to include enclosure integration, cable harness installation, power distribution, firmware configuration, and full system validation.

While PCB assembly confirms electrical functionality at the board level, box build verifies that the complete product operates as an integrated system.

In many projects, yes. Firmware flashing, configuration, and version control are integrated into the box build process to ensure hardware and software alignment.

Managing firmware during assembly reduces the risk of mismatches between hardware revisions and software builds during production.

Industries with performance, compliance, or reliability requirements commonly rely on box build services, including medical device manufacturing, aerospace and defence, industrial automation, telecommunications infrastructure, and energy and power systems. In these sectors, system-level validation and documentation control are essential.

Timelines vary depending on product complexity, enclosure fabrication requirements, supply chain conditions, and testing protocols.

Projects involving custom sheet metal fabrication or multi-board integration typically require additional coordination compared to simpler assemblies. Early engineering review and integrated sourcing help maintain predictable schedules.

From PCB to Production-Ready System

Box build assembly defines the transition from board-level electronics to fully integrated, validated hardware.

Achieving that transition requires coordination across mechanical fabrication, electrical integration, firmware control, and system-level testing. When these disciplines operate within a unified process, production becomes more predictable and scalable.

If you are planning a box build project, connect with the IMS team to review your design files, enclosure requirements, and production targets. Early collaboration helps reduce integration risk and supports a smoother path from prototype to volume manufacturing.