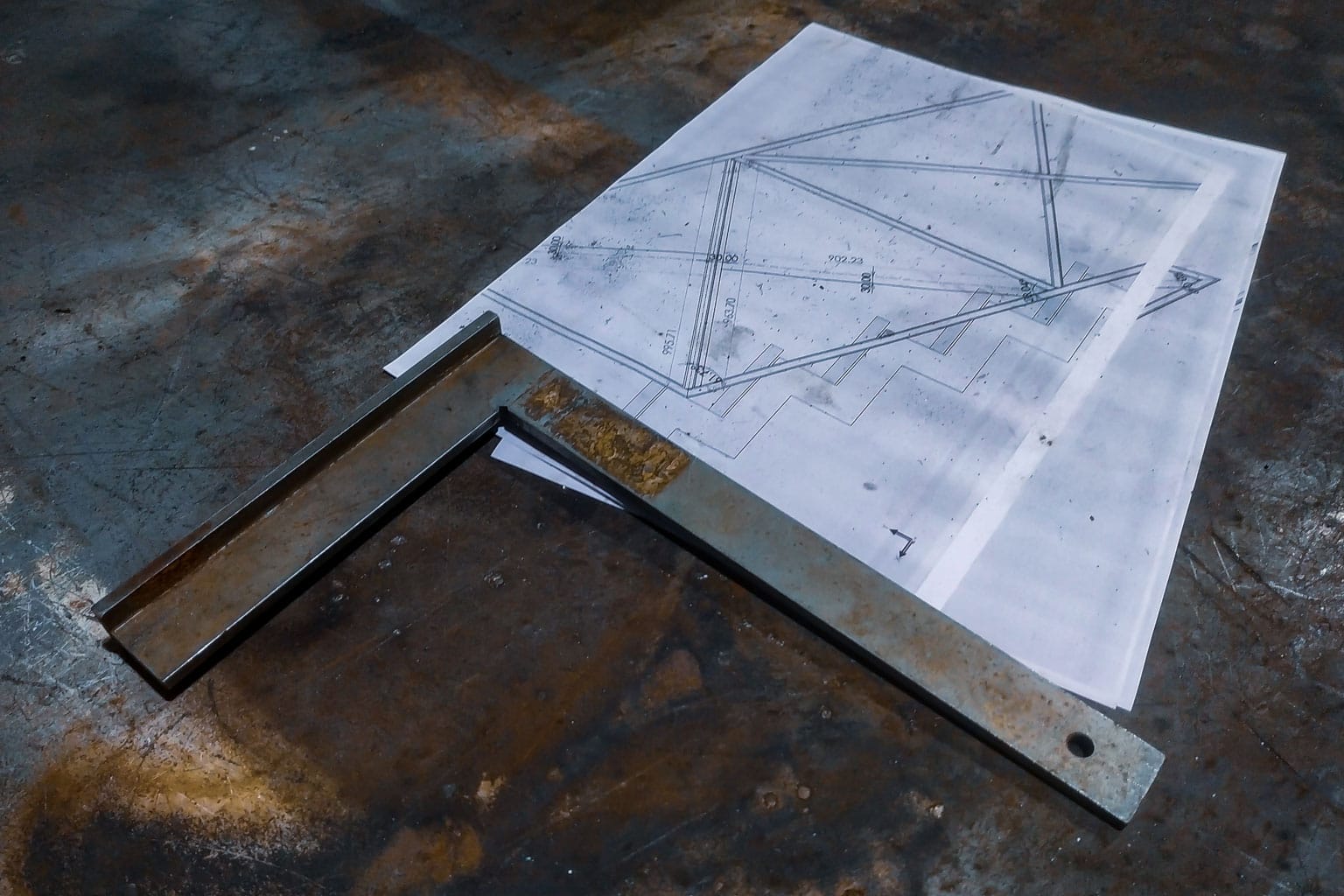

In sheet metal fabrication, small design choices have big consequences. A misplaced hole, an overlooked bend radius, or a tolerance that’s too tight can stall production or drive up costs.

Design for Manufacturability (DFM) focuses on how a part will actually be fabricated—helping teams make smart decisions around bend allowances, tolerances, and part geometry before production begins.

At IMS, we help clients refine their metal designs early—reducing rework and speeding up delivery. Here’s what smart DFM looks like in practice and where it pays off the most.

TL;DR

Design for Manufacturability (DFM) plays a critical role in sheet metal fabrication, where small decisions can affect cost, quality, and lead time. This article outlines common issues like sharp internal corners and tight tolerances, shares key DFM principles for better part performance, and explains how early collaboration with your fabrication partner improves outcomes.

Why DFM Matters in Sheet Metal Fabrication

Designing for sheet metal isn’t like designing for plastic, castings, or 3D printing. It comes with its own set of constraints, like bend allowances, grain direction, tool clearances, and flat pattern geometry. All of these considerations directly affect how a part is formed, cut, and assembled.

Ignoring these details can lead to production slowdowns, material waste, or quality issues. That’s why DFM is so important in metal fabrication: it’s how you design parts that not only function as intended but also work seamlessly with the fabrication process.

At IMS, we help our clients adjust their designs to fit the realities of the shop floor so production runs smoother, parts stay consistent, and lead times stay on track.

Common Design Mistakes That Cost You

Some of the most common production issues start with design decisions. Here are some of the most frequent issues we see and how they impact cost, quality, or lead time:

🚫 Sharp internal corners.

Tight corners can lead to stress points, cracking, or require special tooling. A small radius adjustment often solves the issue and speeds up production.

🚫 Holes too close to bends or edges.

If a hole is placed too close to a bend line, distortion is almost guaranteed. This can lead to part rejection or rework.

🚫 Unrealistic tolerances.

Over-tolerancing a non-critical feature increases inspection time and slows down production unnecessarily.

🚫 Overcomplicated part geometry.

Complex cutouts, overlapping bends, or excessive flange variation can reduce yield and increase machine time.

🚫 Specifying uncommon or difficult-to-source materials.

Choosing a material that’s not regularly stocked can delay production by days—or even weeks.

By flagging these issues early, IMS helps clients simplify their part designs and avoid unnecessary production risks.

🧩 Planning a custom metal project? Check out our Design Tips for Custom Sheet Metal

Fabrication Projects for practical guidance on getting the most from your next build.

Key DFM Principles for Sheet Metal

The best sheet metal designs balance function with fabricability. Here are a few proven DFM guidelines that help ensure consistent, cost-effective parts:

🟢 Use appropriate bend radii.

A good rule of thumb: match the inside bend radius to the material thickness. Tighter bends may require special tooling or cause cracking.

🟢 Respect minimum hole-to-edge and hole-to-bend distances.

Placing holes too close to edges or bends can lead to deformation during forming. Allow for material stretch and tool clearance.

🟢 Standardize features where possible.

Using consistent flange sizes, hole patterns, or tab-and-slot systems simplifies fabrication and reduces set-up time.

🟢 Optimize the flat pattern.

Reducing unnecessary cutouts or complex contours lowers laser or punch time and improves material yield.

🟢 Design for assembly.

Think beyond the individual part. Consider fastener access, part alignment, and whether the design allows for easy installation or stacking.

When these DFM principles are applied early, the result is a design that moves through the shop faster with fewer slowdowns, better repeatability, and cleaner final assemblies.

DFM in Action: How IMS Adds Value

Design for Manufacturability (DFM) is built into how we work with every client. Before any metal part goes to the floor, our team reviews the design to catch potential issues that could slow down production or affect part quality.

We regularly help clients:

- Adjust bend reliefs and radii to reduce tooling wear.

- Improve flat pattern layouts to maximize material use.

- Shift hole placements to avoid distortion during forming.

- Simplify features that don’t impact performance but increase cost.

Because we fabricate parts in-house, we know exactly how they’ll behave on our machines. That means our recommendations are based on real-world outcomes, not theoretical guidelines.

This proactive approach helps reduce rework, shortens lead times, and ensures a smoother transition from design to finished part.

🛠️ Designing a custom bracket or enclosure? Our team can help

review your flat pattern before you commit to production. Talk to us →

When to Bring in Your Fabrication Partner

The best time to think about Design for Manufacturability is before your design is locked in.

Bringing your fabrication partner into the process early (especially during prototyping or design finalization) can help avoid costly changes later. A short design review can flag avoidable production issues, streamline assembly, and reduce back-and-forth between engineering and the shop floor.

We often work directly with product teams to refine designs before production begins. Whether it’s a one-off bracket or a full enclosure assembly, early collaboration helps ensure your part is functional, efficient, and ready for fabrication from day one.

Need a second set of eyes on your metal design?

IMS can help you catch costly issues early—saving time, material, and rework. Connect with our fabrication team to review your next project.