You’ve got your electronics design locked down, components sourced, and production timeline mapped out. Then reality hits: your PCB assembly partner doesn’t handle enclosures, your sheet metal fabricator can’t integrate electronics, and suddenly you’re managing three different vendors with three different timelines.

Sound familiar? This fragmented approach to electronic manufacturing services creates exactly the kind of delays, quality issues, and communication breakdowns that can derail even the most carefully planned projects.

There’s a better way. Integrated box build assembly brings your entire project under one roof, eliminating the hand-offs that create problems and the vendor management headaches that slow you down.

TL;DR

- One team, one schedule: Integrated box build means PCB assembly and enclosure fabrication happen in the same facility—no vendor hand-offs.

- Faster changes, fewer surprises: Mechanical and electronic teams solve fit/finish issues in hours, not weeks.

- Quality at the interfaces: Problems are caught where boards meet brackets, cables, and housings—before they become delays.

- Clear ownership: You get one build record, one contact, and predictable costs from prototype to production.

What Is Integrated Box Build—and Why It’s Different

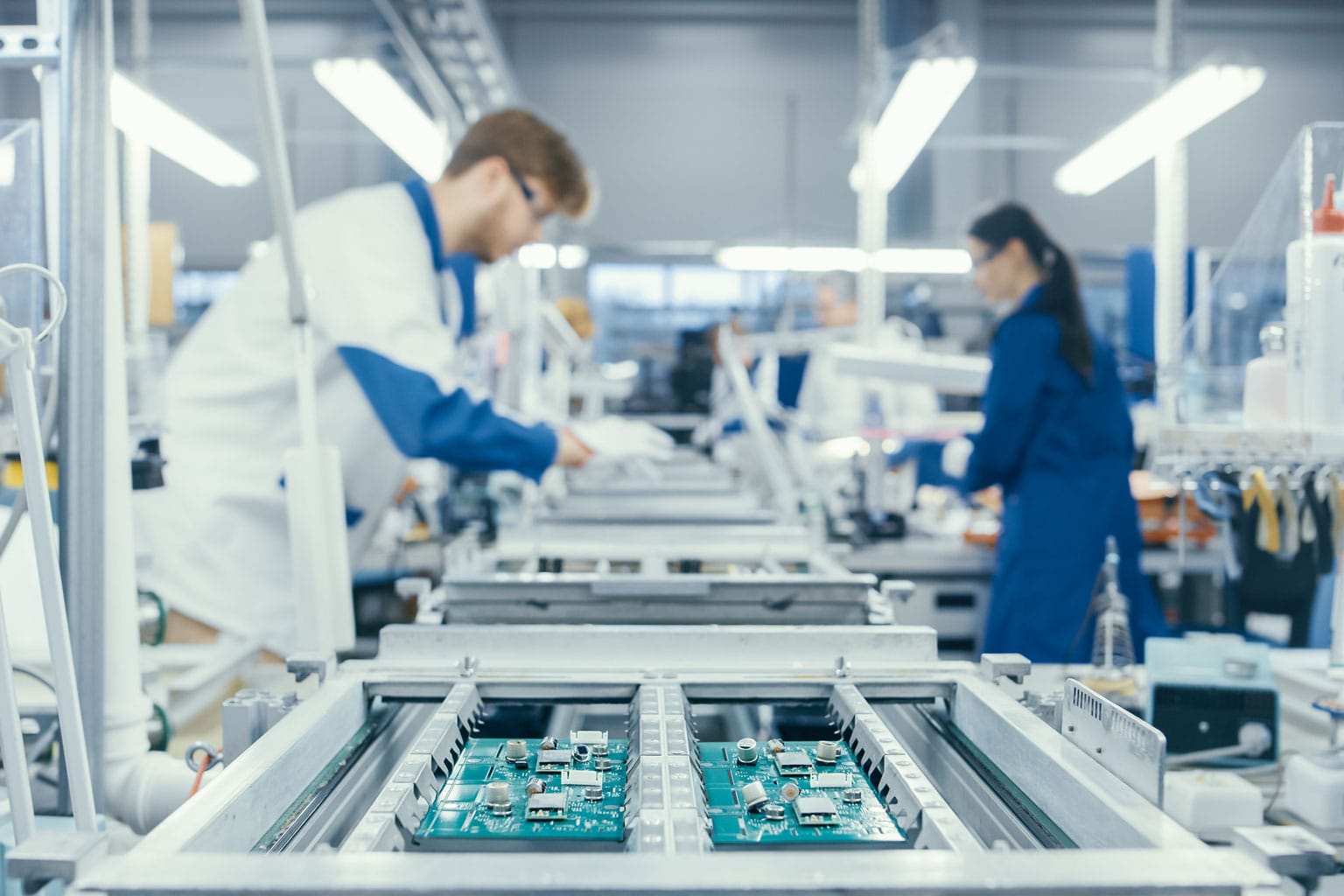

Box build assembly transforms individual components—PCBs, wiring, power supplies, and enclosures—into complete, market-ready products. But there’s a crucial difference between standard box build services and truly integrated electronic manufacturing services.

Standard box build (typical):

- PCBs assembled at one location

- Enclosures sourced from another supplier

- Final integration happening at a third facility

- Multiple vendors to coordinate and manage

Integrated box build (one roof):

- PCB assembly and testing

- Custom enclosure design and fabrication

- Complete system integration and final testing

- Single point of contact throughout the entire process

This integration eliminates the gaps where projects typically run into trouble: miscommunication between vendors, shipping delays between facilities, and quality issues that surface when components from different sources don’t work together as expected.

Learn more about the differences between Box Build and PCB Assembly here.

The Business Case for Integrated Electronic Manufacturing Services

1. Ship Faster

When your electronics manufacturer handles both PCB assembly and enclosure fabrication, there’s no waiting for components to ship between vendors. Design changes can be implemented immediately across both electronic and mechanical elements.

Instead of coordinating separate timelines from multiple suppliers, you get a single, realistic delivery date. What might take months when coordinating multiple vendors can often be delivered weeks faster through integrated manufacturing.

2. Catch Issues Earlier

Quality problems in box build assembly usually happen at the interfaces—where components from different vendors meet. Maybe the PCB mounting holes don’t align perfectly with the enclosure. Perhaps the cable lengths are wrong because the enclosure dimensions changed slightly during fabrication.

With integrated electronic manufacturing services, these interface issues are caught and resolved before they become problems. The same engineering team that designs your enclosure understands exactly how your PCBs will mount inside it. Quality control happens across the entire assembly, not just individual components.

3. Simplify Project Management

Managing multiple vendors means multiple project managers, different communication styles, and constant coordination to keep everything aligned. When your electronics manufacturer provides integrated box build assembly, you have one contact who understands the entire project.

Need to make a design change? One conversation handles both electronic and mechanical implications. Questions about timeline? You get answers that account for the complete manufacturing process, not just one piece of it.

4. Get Predictable Costs

Integrated manufacturing eliminates many of the hidden costs that surface in multi-vendor projects. No shipping costs between facilities. No markup from intermediary vendors. No rush charges when one vendor’s delay forces another to expedite their work.

You get transparent pricing for the complete project upfront, making budgeting simpler and reducing the financial surprises that can derail project approvals.

What Makes Integration Possible: The One-Roof Advantage

Not all electronics manufacturers can deliver truly integrated box build assembly. It requires specific capabilities that most electronic manufacturing services simply don’t have in-house.

🟡 Custom Enclosure Design and Fabrication

Many EMS providers source enclosures from outside suppliers. True integration requires in-house sheet metal fabrication capabilities—the ability to design, cut, form, and finish custom enclosures that perfectly match your electronic requirements.

🟡 Cross-Functional Engineering Teams

Successful integration demands engineers who understand both electronics and mechanical design. When the same team handles PCB layout and enclosure design, they can optimize both for manufacturing efficiency and final product performance.

🟡 Flexible Manufacturing Systems

Integrated box build assembly requires production systems that can handle both high-precision electronics work and robust mechanical assembly. This means specialized equipment, trained technicians, and quality systems that work across multiple manufacturing disciplines.

IMS: Where Electronics and Enclosures Come Together

At IMS, integrated box build assembly isn’t just a service we offer; it’s how we’re designed to operate. Our facility combines advanced electronics manufacturing with complete sheet metal fabrication capabilities, allowing us to handle your entire project from prototype to production.

✅ Electronics Manufacturing Expertise

Our electronics shop handles everything from PCB assembly using Surface Mount Technology (SMT) and Through-Hole Technology (THT) to complete system testing. We work with components ranging from simple control circuits to complex multi-layer assemblies for demanding applications.

✅ Custom Sheet Metal Fabrication

Our in-house metal shop designs and fabricates custom enclosures, brackets, and chassis tailored to your specific requirements. Whether you need a simple protective housing or a complex multi-compartment enclosure, we handle the complete fabrication process, including cutting, forming, welding, and finishing.

✅ Seamless Integration Process

When your PCB assembly team and enclosure fabrication team work in the same facility, collaboration happens naturally. Design reviews include both electronic and mechanical considerations. Testing protocols verify complete system performance, not just individual components.

This integration has helped customers in industries from industrial automation to renewable energy get their products to market faster and with fewer complications.

When Integration Matters Most

Integrated box build assembly delivers the biggest advantages in specific scenarios:

⭐ Custom Product Development

When you’re creating something new, standard enclosures rarely fit perfectly. Integrated electronic manufacturing services allow you to optimize both the electronics and enclosure design simultaneously, creating better products in less time.

⭐ Mid-Volume Production

Projects requiring 50 to 5,000 units often fall into a difficult space. Too large for prototype services, too small for high-volume offshore manufacturing. Integrated domestic manufacturing provides the flexibility and efficiency these projects need.

⭐ Quick-Turn Projects

When deadlines are tight, eliminating vendor coordination and shipping delays can mean the difference between hitting your launch date and missing your market window.

⭐ Complex Assembly Requirements

Products with demanding environmental requirements, custom mounting solutions, or specialized testing needs benefit from having all manufacturing expertise under one roof.

Making the Right Choice for Your Project

Electronic manufacturing services have evolved beyond simple PCB assembly. Today’s successful products require manufacturing partners who can handle complete system integration, bringing together electronics, mechanical components, and testing into a cohesive process.

The question isn’t whether you need box build assembly. The question is whether you want to manage multiple vendors and risk the delays and quality issues that come with fragmented manufacturing or work with an electronics manufacturer who can handle your complete project.

At IMS Electronics Manufacturing, we’ve built our capabilities specifically to eliminate the complications that slow down product development and manufacturing. Our integrated approach to box build assembly helps customers move from concept to market-ready product more efficiently.

Ready to simplify your next electronics project?

Our team can walk you through how integrated manufacturing works for your specific requirements. Contact IMS today to discuss your box build assembly needs.