Our Facility

Tech at Work: The Machinery Making It Happen

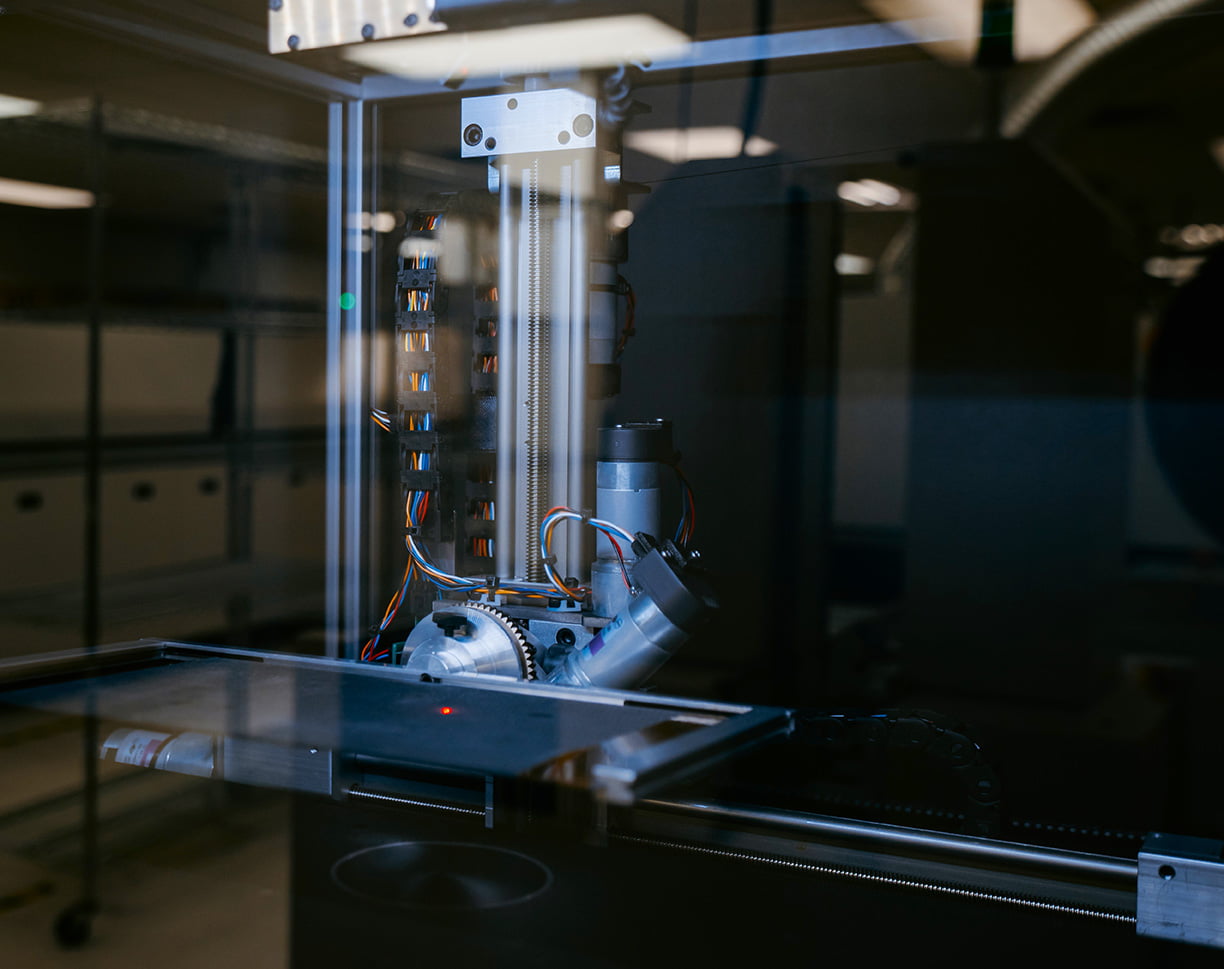

From precision engineering tools to state-of-the-art robotics, each piece of equipment in the IMS facility plays a pivotal role in delivering products that meet our high standards. Combined with our team’s expertise, this machinery ensures efficiency and accuracy with every project, making your concepts a tangible reality.

Precision Inspection and Assembly

Vi Technology Pi Primo

Measures the height, volume, and area of solder paste deposits, preventing defects early and ensuring higher-quality PCBs.

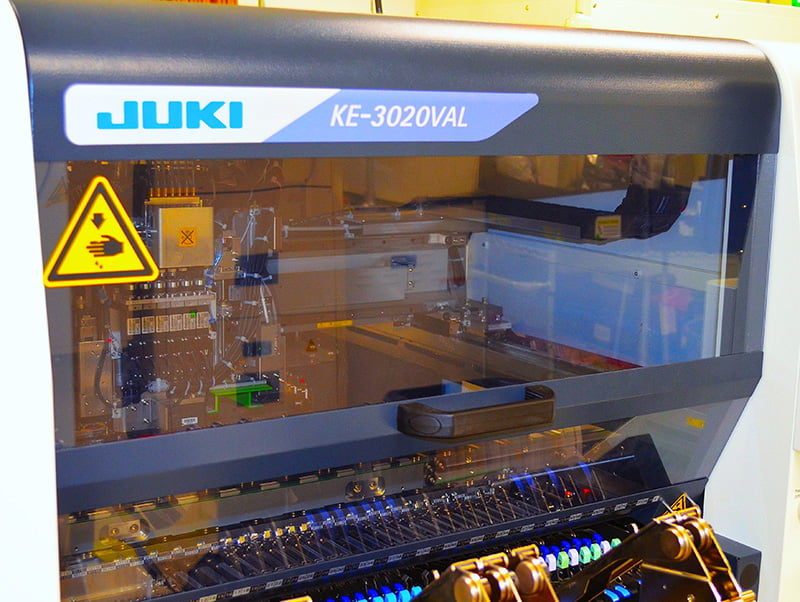

Surface Mount Pick and Place Systems (P&P)

Juki RS1 and Juki KE3020VAL

Precise placement of SMT parts, handling components from the smallest to the largest with an accuracy of +/- 0.03mm at a speed of approximately 46,000 parts per hour.

Automated Optical Inspection (AOI)

Advanced Testing and Quality Assurance

X-ray Inspection System

Glenbrook Technology Jewelbox

Inspects hidden solder joints (BGAs and other leadless devices) to confirm they meet specifications, ensuring structural integrity.

Innovative Molding and Processing

Low Pressure Molding Machine

Accurate and Efficient Storage Solutions

“I have been working with IMS for a few years now, and I cannot express enough how impressed I am with their exceptional service every time. From the initial project consultation to the final delivery, the team is professional, attentive, and dedicated to meeting my needs. I highly recommend IMS to anyone seeking high quality manufacturing solutions. Thank you for a fantastic experience!” – GC

“I have been working with IMS for a few years now, and I cannot express enough how impressed I am with their exceptional service every time. From the initial project consultation to the final delivery, the team is professional, attentive, and dedicated to meeting my needs. I highly recommend IMS to anyone seeking high quality manufacturing solutions. Thank you for a fantastic experience!” – GC