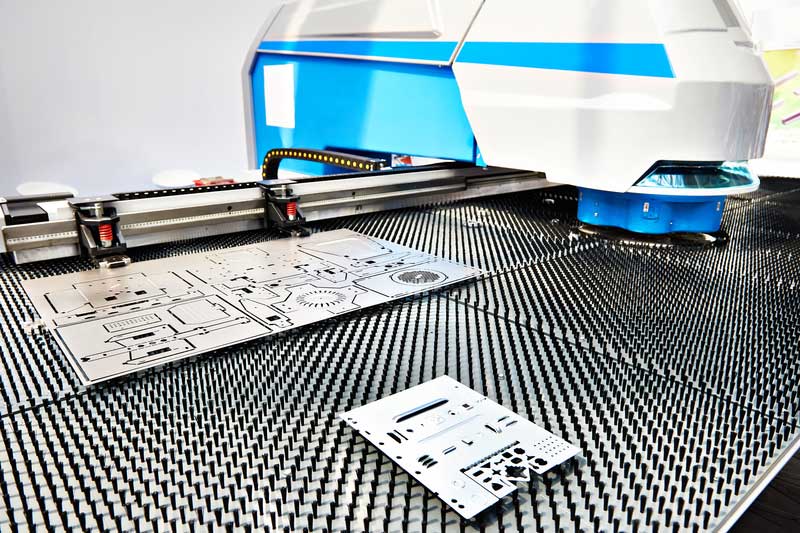

At IMS, sheet metal fabrication is our specialty! We take pride in our superior customer service and commitment to excellence. Our business is built on integrity, honesty and hard work. Sheet metal fabrication requires specialized machinery and technology. We use the Precision Trumpf CNC Punch Press.

What is a punch press?

A punch or punching press uses pre-formed dies and punches to transform sheet metal blanks into formed products and parts. The punches pass through the sheet metal, while the dies are located on the opposite side of the metal sheet. As the punch moves downwards into the die, the sheet metal beneath the punch is sheared from the surrounding material. The scrap pieces of metal that are sheared off (slugs) are collected and recycled.

What are the benefits of using a punch press?

The punching process:

- creates cost-effective holes in sheet metal during medium and high-volume manufacturing processes.

- easily create holes in various shapes and eliminates the need for secondary forming operations.

- creates precise shapes to the highest level of quality, free from needle holes, spatter, waves and/or scratches.

- completes many processing steps; punching, slitting, forming, countersinking, tapping, rolling, marking and deburring.

- allows various parts to be processed in the machine, saving setup and programming time.

- can be automated, saving time and increasing precision.

- outperforms all other technologies in speed and cost-effectiveness.

- makes processes fluid and safe.

- allows all tools to be positioned in any tool station regardless of their size.

How does a punch press work?

A programmer enters a 2D flat pattern into the software. They select tools from a library to produce the flat part, using a combination of metal hole-punching techniques. This creates the G-Code (or CNC code). The uploaded code determines which tools the CNC punch press will use at which locations. The operator loads the correct tooling and calibrates the machine. Then the punch press reads the code at an extremely high rate of speed to create the part.

Why use the Trumpf TruPunch 1000 CNC press?

At IMS we use the Trumpf TruPunch 1000 as it offers flexible processing of a diverse range of parts. It provides the option of reforming metal parts or tapping. It holds up to 15 different tools with various shapes while the punching head rotates tools in any angular position, minimizing set-up time and increasing productivity. An active and retractable die ensures optimum part quality. Intelligent automation options create ease for the operator and increase output. Complete metal components can be manufactured on a TRUMPF punching machine via metal punching, slitting, forming, countersinking, rolling, marking, deburring and tapping. Sorting and removal are easier than ever before. The Trumpf TruPunch is a time-saving technology for many applications.

Using the Precision Trumpf CNC Punch Press enables IMS to offer precision, speed and affordable sheet metal fabrication services. We produce complex shapes, repeatedly, accurately, quickly and at a great price.

Contact IMS to discuss options available for your sheet metal fabrication needs.