Choosing the right enclosure manufacturing process affects more than just how your product looks. It impacts your project cost, production timeline, design flexibility, and ability to scale from prototype to volume production. Get it right, and your enclosure supports efficient assembly and reliable performance. Get it wrong, and you face expensive redesigns, delayed launches, or compromised product quality.

Many engineering teams default to a manufacturing process based on familiarity rather than fit. They choose CNC machining because it’s what they’ve always used, or they select sheet metal fabrication without fully understanding when each approach makes sense.

There’s no universal “right” answer. The best enclosure manufacturing choice depends on your specific project requirements, including production volume, budget constraints, timeline pressures, and how your enclosure integrates with your electronics assembly.

This guide breaks down the practical differences between sheet metal fabrication and CNC machining for electronics enclosures, helping you choose the process that supports your full project, not just the enclosure itself.

TL;DR

- Sheet metal fabrication creates enclosures from flat sheets through cutting, bending, and forming. It’s generally more cost-effective than CNC machining across most volume ranges.

- CNC machining removes material from solid blocks, making it better for low volumes (1-20 units), extremely tight tolerances, or highly complex geometries.

- Cost difference can be significant. Sheet metal typically costs less at volumes above 50-100 units; CNC typically stays more expensive regardless of quantity.

- Scalability matters. Sheet metal transitions smoothly from prototype to production; CNC-machined designs often require redesign when scaling.

- Choose based on your full project. Consider volume expectations, budget, timeline, and integration with electronics assembly, not just the enclosure in isolation.

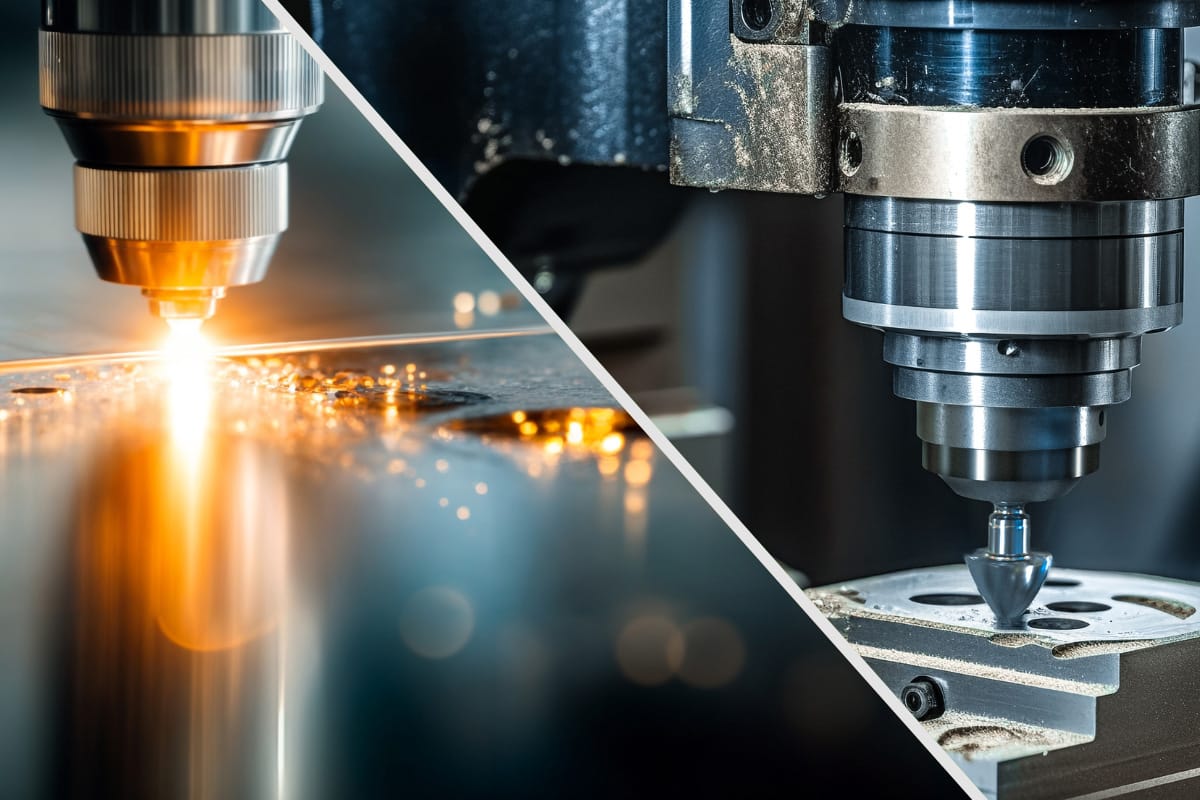

What Is Sheet Metal Fabrication?

Sheet metal fabrication transforms flat metal sheets into three-dimensional enclosures through cutting, bending, forming, and finishing processes. Starting with standardized sheet stock (typically aluminum, steel, or stainless steel), manufacturers create enclosures by:

→ Cutting the flat pattern using laser cutting, punching, or waterjet processes to create the basic shape.

→ Bending and forming the flat pattern into three-dimensional geometry using press brakes and forming equipment.

→ Joining components through welding, riveting, or hardware fasteners when designs require multiple pieces.

→ Finishing with powder coating, anodizing, or other surface treatments for durability and appearance.

For electronics projects, common sheet metal fabrication materials include:

- Aluminum (lightweight, excellent electrical properties, easy to finish)

- Cold-rolled steel (cost-effective, strong, readily available)

- Stainless steel (corrosion-resistant, durable for harsh environments)

- Galvanized steel (outdoor applications requiring weather resistance)

Sheet metal fabrication excels for electronics enclosures requiring:

- Lightweight construction without sacrificing strength

- Cost-effective production at low to mid volumes

- Quick turnaround from design to finished parts

- Easy integration with electronic assemblies and mounting hardware

What Is CNC Machining?

CNC (Computer Numerical Control) machining creates enclosures by removing material from solid metal blocks using computer-controlled cutting tools. Mills, lathes, and multi-axis machining centers precisely cut away material to create the desired geometry.

The CNC machining process involves:

→ Starting with solid stock (aluminum billet, steel bar stock, or other solid material blocks).

→ Removing material through multiple machining operations (facing, drilling, milling, boring) to create the final geometry.

→ Achieving tight tolerances that sheet metal processes typically can’t match (often ±0.001″ or tighter).

→ Creating complex geometries, including undercuts, pockets, and features that would be impossible or impractical with sheet metal.

CNC machining works well for electronics enclosures when projects require:

- Extremely tight dimensional tolerances

- Solid, heavy-duty construction

- Complex three-dimensional geometries

- Very low volumes where tooling costs don’t make sense

- Specific material properties that sheet stock doesn’t provide

Sheet Metal Fabrication vs. CNC Machining: Key Differences

Understanding the practical differences helps you match the process to your project requirements.

1. Cost Considerations

Sheet metal fabrication typically offers lower per-unit costs at volumes above 50-100 units. Tooling costs (press brake dies, punches) are modest and amortize quickly. Material costs stay low since you’re buying sheet stock, not removing excess material.

CNC machining carries higher per-unit costs because:

- Machine time is expensive (cutting away material takes time)

- Material waste is significant (you’re removing 40-80% of the starting block)

- Programming and setup add costs for each unique geometry

For prototype quantities (1-10 units), CNC costs may be competitive. At volumes above 50 units, sheet metal fabrication almost always costs less per part.

2. Production Speed and Lead Times

Sheet metal fabrication generally delivers faster once tooling is established. Cutting and bending operations are quick—often minutes per part. Multiple parts can be nested on single sheets for efficient production.

CNC machining requires longer cycle times as tools gradually remove material. Complex geometries might require hours of machine time per part, and machine scheduling can extend lead times when facilities are busy.

For time-sensitive projects, sheet metal fabrication typically offers faster delivery, especially at volumes beyond prototypes.

3. Design Flexibility

Sheet metal fabrication works best for designs based on bends and flat patterns. Simple to moderately complex geometries are straightforward. Very complex three-dimensional curves or undercuts may be challenging or impossible.

CNC machining handles almost any geometry a designer can create, including pockets, undercuts, complex curves, and intricate details, all machined predictably.

However, designing for sheet metal fabrication from the start often results in simpler, more cost-effective enclosures that are easier to assemble and service.

4. Scalability from Prototype to Production

Sheet metal fabrication scales smoothly from prototype through production. The same process that produces 10 units works for 1,000 units with only minor setup changes. Transitioning from prototype to volume production is straightforward.

CNC machining doesn’t always scale cost-effectively beyond low volumes. What works for 10 prototypes becomes prohibitively expensive at 500 units. Many projects start with CNC-machined prototypes but transition to sheet metal fabrication for production, requiring design modifications and re-validation. Another option for volume production: Projects can transition to cast parts with CNC finish machining. Cavities and features are molded into the casting, with only tight-tolerance holes machined afterward. This approach maintains the precision of machining while greatly reducing per-unit costs at higher volumes.

5. Weight and Material Efficiency

Sheet metal fabrication creates lightweight enclosures using thin material (typically 0.040″ to 0.125″ thick). This is ideal for portable equipment, reducing shipping costs, and minimizing weight where it matters.

CNC machining starts with solid blocks, resulting in heavier enclosures even after material removal. While you can machine thin walls, the process is less efficient than sheet metal fabrication for creating lightweight structures.

6. Design Change Tolerance

Sheet metal fabrication accommodates design changes relatively easily. Modifying bend angles, adding holes, or adjusting dimensions typically requires minor tooling updates or reprogramming.

CNC machining handles design iteration well during prototyping since changes are just programming updates. However, if you’ve invested in custom fixturing or multi-part setups, changes become more complicated.

When Sheet Metal Fabrication Is the Better Choice

Sheet metal fabrication makes sense for electronics projects when:

✓ Volume expectations exceed 50-100 units. Cost advantages become significant as quantities increase. Even at 50 units, sheet metal fabrication often costs less per part than CNC machining.

✓ Budget sensitivity matters. Projects with tight cost targets benefit from sheet metal fabrication’s material efficiency and fast production cycles.

✓ Weight is a consideration. Portable equipment, handheld devices, or applications where shipping costs matter favour lightweight sheet metal enclosures.

✓ Timelines are aggressive. Fast turnaround from order to delivery often points toward sheet metal fabrication, especially when volumes justify the process.

✓ Design may evolve. Products still being refined or expecting updates benefit from sheet metal fabrication’s flexibility for changes.

✓ Integration with electronics assembly matters. When enclosures need to accommodate circuit board assembly, mounting brackets, cable routing, and grounding considerations, sheet metal fabrication offers practical advantages for creating mounting features, access panels, and assembly-friendly designs.

When CNC Machining May Be the Better Fit

CNC machining serves electronics enclosure projects best when:

✓ Volumes are very low (1-20 units). At prototype or small pilot run quantities, CNC machining can be cost-competitive, especially for simple geometries.

✓ Tolerances are extremely tight. Applications requiring ±0.001″ tolerances or better, precise mating surfaces, or critical dimensional control may need CNC machining’s accuracy.

✓ Geometry is highly complex. Designs with deep pockets, complex curves, integrated mounting features, or undercuts that sheet metal fabrication can’t achieve may require machining.

✓ Material requirements are specific. When you need specific alloys, solid block construction, or material properties that sheet stock doesn’t provide, CNC machining offers more material options.

✓ Prototype validation before production tooling. Some teams machine prototypes to validate fit and function before committing to sheet metal fabrication tooling for production, though this requires design for both processes.

How Electronics Project Teams Should Decide

Choosing between sheet metal fabrication and CNC machining requires considering multiple factors together, not in isolation.

Start with volume expectations.

If you’re planning more than 50 units, sheet metal fabrication likely offers better economics. Below 20 units, CNC machining may be competitive.

Consider your budget realistically.

Calculate cost per unit at your expected volumes, not just prototype pricing. Sheet metal fabrication costs decrease with volume; CNC costs stay relatively flat.

Factor in timeline pressures.

Aggressive delivery schedules often favour sheet metal fabrication’s faster production cycles.

Think about future scaling.

If your prototype might become a product, choosing sheet metal fabrication from the start avoids redesign when scaling to production.

Evaluate enclosure integration needs.

How does your enclosure work with your electronics assembly? Consider mounting points, cable routing, access for assembly, and serviceability. Sheet metal fabrication often provides more practical solutions for these integration challenges.

Consider manufacturing consolidation.

Working with a partner who handles both enclosure fabrication and electronics assembly under one roof simplifies coordination, reduces handoffs, and typically speeds overall project delivery.

A quick conversation with your manufacturing partner during design can clarify which process best suits your specific requirements before you’ve committed to a direction that might not scale well.

Why Process Choice Impacts More Than the Enclosure

Your enclosure manufacturing decision affects your entire electronics project, not just the housing:

Assembly efficiency depends on how easily your enclosure accommodates board mounting, cable routing, and component access. Sheet metal fabrication makes it straightforward to add mounting features, cutouts, and access panels that support efficient assembly.

Grounding and shielding rely on proper enclosure design. Metal enclosures provide excellent EMI shielding, but implementation details matter. Sheet metal fabrication allows for integrated grounding features and conductive paths that CNC machining can match but may require additional operations to achieve.

System reliability benefits from enclosures designed for proper heat dissipation, vibration resistance, and environmental protection. Both processes can deliver these characteristics, but sheet metal fabrication often does so more cost-effectively.

Service and maintenance considerations include how easily technicians can access components for troubleshooting or replacement. Removable panels, hinged doors, and access plates are typically easier to implement with sheet metal fabrication.

This is why experienced electronic manufacturing services partners consider enclosures as part of the complete system, not as isolated components. Design decisions that seem minor for the enclosure can significantly impact assembly costs, product reliability, and field serviceability.

Choose the Process That Supports the Full Project

There’s no universal “right” answer to sheet metal fabrication vs. CNC machining. The best choice depends on your specific project: volume, budget, timeline, design requirements, and how your enclosure integrates with your electronics.

What matters most is planning early and working with partners who understand electronics as a complete system, not just individual components manufactured in isolation.

At IMS, we handle both sheet metal fabrication and circuit board assembly under one roof. This integrated approach means we can recommend the enclosure process that actually supports your full project requirements, not just optimize one piece independently.

Whether your project calls for sheet metal fabrication, CNC machining, or a combination approach (machined prototypes transitioning to sheet metal production), we help teams make decisions that support successful products—from initial prototypes through volume manufacturing.

Need guidance on enclosure manufacturing for your electronics project? Our team can review your requirements and recommend the approach that balances cost, timeline, and performance for your specific application.

Contact IMS today to discuss your project and learn how our integrated manufacturing simplifies your path from design to delivery.