Cable assemblies are useful for keeping your applications working smoothly and safely, whilst keeping cost and maintenance low. When working with wires and cables, it is nearly impossible to achieve the same efficiency without a well-designed cable assembly.

What is a cable assembly?

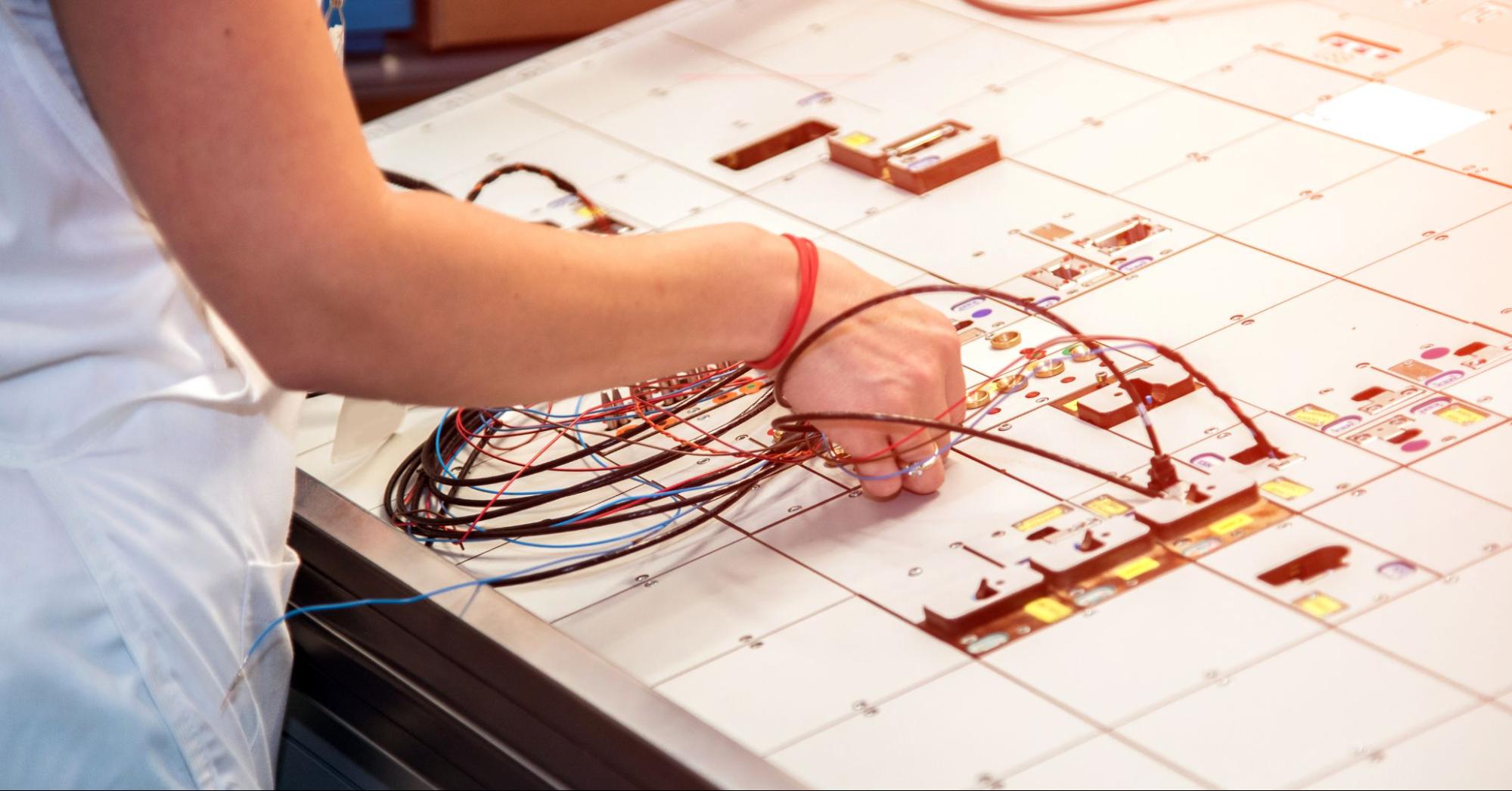

A cable is two or more conductors wrapped in a single jacket. Most cables consist of a positive wire (carries the electrical current), a neutral wire (completes the electrical loop) and a grounding wire (connects the system to the earth). A cable assembly, also called a cable harness or wiring loom, is a group of cables encased in a singular tube of material (rubber, vinyl or thermoplastic).

The cables are grouped together in the required length and orientation, making them easier to install, replace, and maintain. A cable assembly may include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve or taped/bound with cable ties, grouping the cables together, protecting them and making them more compact. The assembly may be fitted with various terminations, including plug or socket arrangements. They are used to connect a machine to a power, data or networking signal.

These ready-to-install assemblies don’t require stripping or terminating to attach connectors, simplifying machine design. They reduce environmental damage and protect signal integrity from contamination from dirt and liquids, EMI and other electrical interference and impact or strain from pulling or tugging on the cables. This protection reduces the possibility of problems with the machinery due to issues such as shorts in the wiring.

Cable assemblies are used in a variety of applications (mobile machinery, industrial automation, military, aerospace, oil and gas, and medical devices). The specific design depends upon its use and the needs of the user.

What is a cable assembly used for?

Cable assemblies hold/organize electrical wires safely, making them useful for a variety of indoor and outdoor settings. They’re used in mass production to save time during the assembly of machines/equipment. Cable assemblies are used in aerospace equipment, the automotive industry, medical apparatus, telecommunications and information technology, construction, manufacturing, robotics and automation.

Benefits of Cable Assemblies:

There are many benefits to having a cable assembly as part of your system. The advantages of cable assemblies include:

- Saves time: Assemblies group cables, speeding installation for large or complex systems. This organization makes it easier to identify and locate the appropriate components. A cable assembly improves the time spent on investigation, should something need fixing.

- Safety: They provide insulation and shielding to protect against dangerous shorts and keep wires contained to avoid accidents in the workplace.

- Improved quality: A cable assembly can be customized to fit the requirements of an application. This includes labelling the different wires and cables together for simple installation and less confusing connectors. These assemblies are tested under extreme circumstances to ensure that they won’t be liable to fail. The quality of the system is greatly increased, ensuring efficient production.

- Organization: Cable assemblies are contained within one area, rather than being spread out and tangled. This is important in heavy-duty applications as the movement of the individual components is easier and there is less risk of damaging the cables. It also means the safety of employees isn’t jeopardized.

What are the variations of a cable assembly?

There are readily available cable assemblies on the market and customizable assembly solutions. Some of the most popular types of cable assembly are:

- Flat and ribbon cable assemblies: This refers to a wide selection of multi-purpose cable assemblies (split, multi-branch, non-PVC, etc.). The wires are laid parallel, making them perfect for application in tight spaces.

- High-speed data assemblies: These consist of multiple micro-coax and twinax cables that optimize high-speed data performance and fit into tight spaces.

- Shielded cable assemblies are used specifically to protect the assembly from electromagnetic interference through the help of shielding. The individual wires are placed inside an EMI braided sleeve and an additional sleeve that protects from abrasion.

- Sealed cable assemblies offer superior protection from moisture, humidity and dust.

- Jacketed cable assemblies may be needed in medical establishments because wires must follow specific sterilization rules.

- Custom cable assemblies are available with a specific goal in mind and can be grouped according to voltage and power.

A cable assembly is an important component of many systems. Choosing and designing the right one for your application can be a time-consuming process. An experienced team can help you design a cable assembly to suit your requirements and your applications.

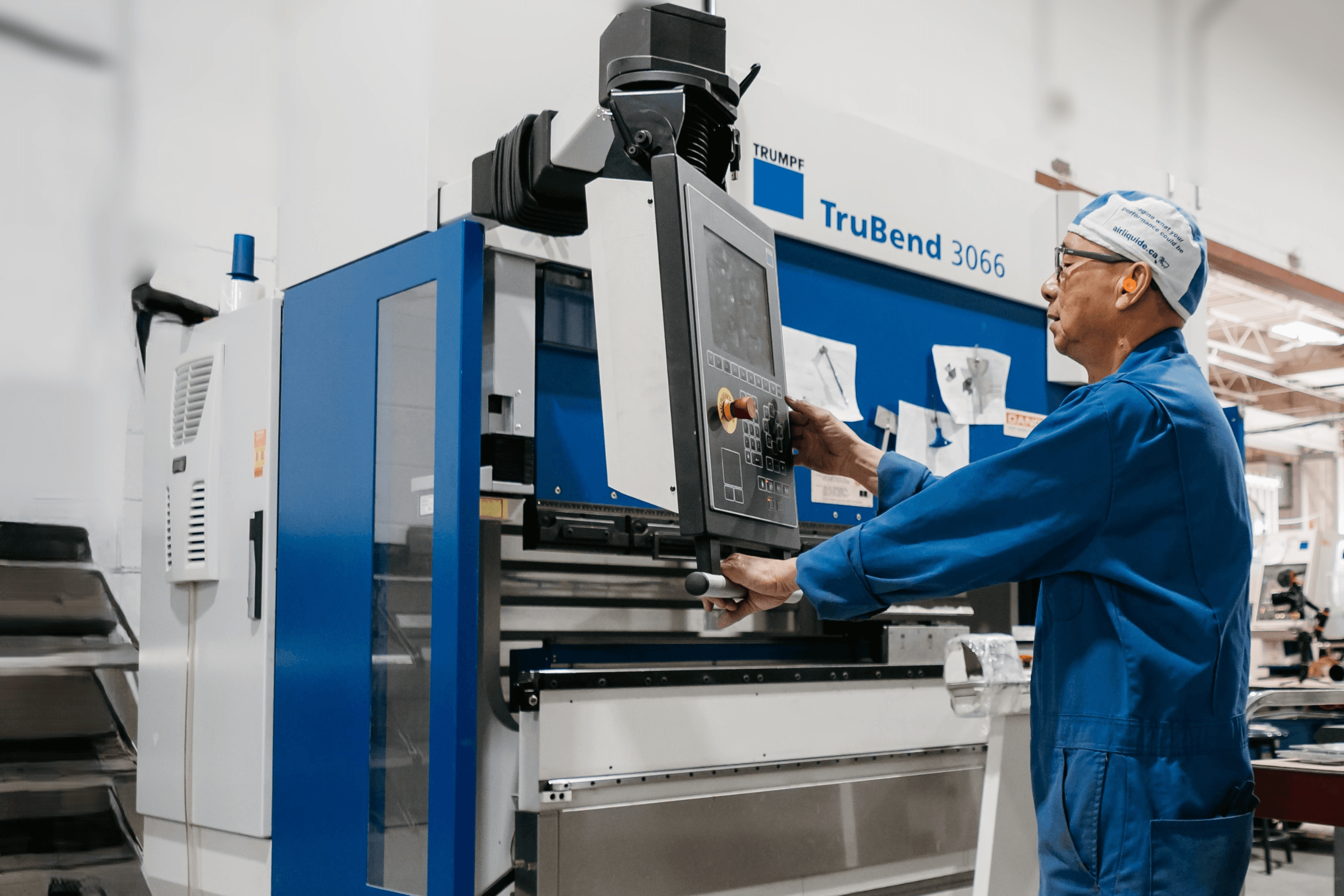

Need a custom cable assembly? Contact Calgary-based Innovative Manufacturing Source (IMS). Our team of knowledgeable, skilled, dedicated people offer unsurpassed service and product. We serve you through in-house manufacturing capabilities completed on state-of-the-art equipment. Call us at 403.279.7702 for all your cable assembly needs.