Your PCB quality determines your product’s success—or failure. A single weak solder joint, misaligned component, or undetected defect can lead to downtime, safety hazards, or costly recalls.

At IMS Electronics Manufacturing, we know that high-reliability PCBs demand precision engineering, top-tier materials, and rigorous quality control. Whether your circuit boards power medical devices, industrial automation, or aerospace systems, ensuring long-term durability starts with the right manufacturing partner.

1. High-Quality PCB Materials

The materials used in a PCB directly impact its thermal resistance, conductivity, and long-term reliability. High-performance applications such as aerospace, automotive, and medical devices require robust materials that withstand stress and environmental factors.

Important Material Considerations:

- Substrate Material: FR4 (fiberglass-reinforced epoxy laminate) is the industry standard, but high-frequency applications may require PTFE (Teflon), ceramic, or metal-core PCBs.

- Copper Thickness: A thicker copper layer improves current-carrying capacity and durability in power electronics.

- Surface Finish: ENIG (Electroless Nickel Immersion Gold) and HASL (Hot Air Solder Leveling) provide better solderability and corrosion resistance.

- Heat Dissipation: Proper thermal management materials prevent overheating and premature board failure.

PCBs used in extreme conditions, such as aerospace, industrial automation, and outdoor applications, must be engineered for resilience. From specialized substrates to advanced coatings, the right materials make all the difference. Learn more about best practices for PCB assembly in harsh environments here.

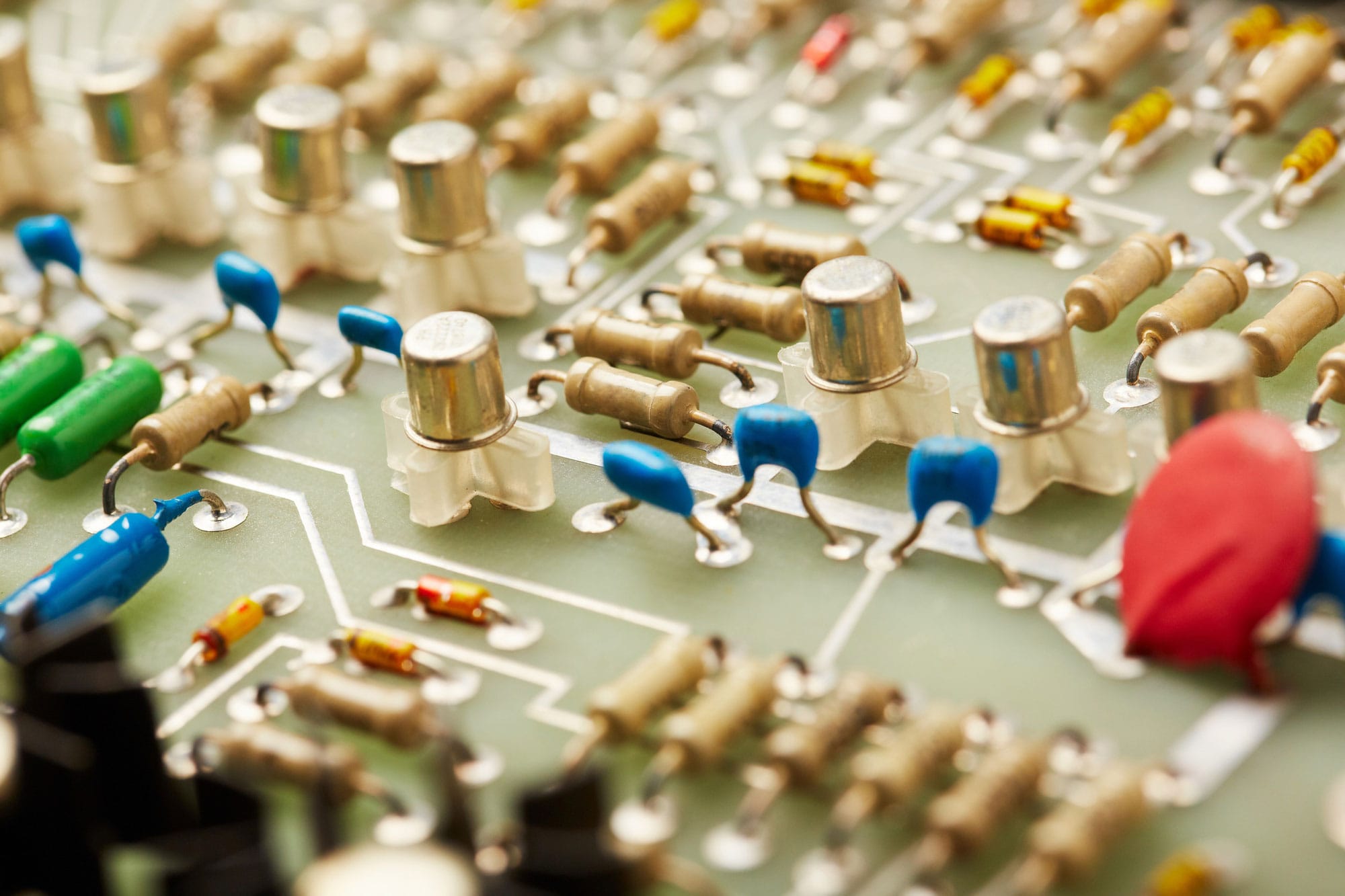

2. Precision Soldering & Component Placement

A high-quality PCB assembly relies on accurate soldering and precise component placement to ensure electrical continuity and performance. Poorly soldered joints or misaligned components can lead to short circuits, cold solder joints, and long-term reliability issues.

Critical Factors for Soldering & Placement:

- Automated SMT & Through-Hole Assembly: Surface mount technology (SMT) and through-hole soldering require automated precision to prevent misalignment and defects.

- IPC Standards Compliance: High-quality PCBs adhere to IPC Class II & III standards, ensuring solder joints are clean, uniform, and defect-free.

- Solder Paste Application: Proper solder paste deposition is crucial for avoiding bridging, insufficient solder, or excessive flux residue.

- Component Lead Integrity: Ensuring strong, durable connections prevents failures under mechanical or thermal stress.

IMS utilizes high-precision pick-and-place machines for SMT assembly, ensuring exact component placement. Our reflow ovens and wave soldering systems guarantee strong, reliable solder joints, minimizing the risk of defects in high-performance applications. Check out our state-of-the-art-machinery.

3. Rigorous Testing & Quality Control Measures

Even the best-designed PCB assemblies can fail if not thoroughly tested. Comprehensive inspection and validation ensure that every assembled circuit board meets strict performance and reliability criteria.

PCB Testing Methods for Reliability:

- Automated Optical Inspection (AOI): Detects solder joint defects, component misalignment, and missing parts using high-resolution imaging.

- X-ray Inspection: Ensures quality control of hidden solder joints, especially for BGA (Ball Grid Array) and QFN (Quad Flat No-Lead) components.

- In-Circuit Testing (ICT): Verifies electrical performance, continuity, and resistance values to catch manufacturing defects early.

- Functional Testing: Simulates real-world conditions to validate board performance under operating loads.

- Burn-In Testing: Stress tests PCBs at elevated temperatures and voltages to identify potential early failures.

IMS deploys multi-step testing protocols to guarantee that each assembled circuit board leaving our facility meets the highest quality standards for performance and longevity. We stand by our craftsmanship with a one-year warranty, ensuring your product is backed by industry-leading quality assurance.

4. Clean & Contaminant-Free Manufacturing Environment

Microscopic contaminants, such as dust, moisture, or flux residue, can compromise PCB performance over time. A controlled cleanroom environment is critical to prevent contamination during assembly.

How Clean Manufacturing Impacts PCB Reliability:

- Prevents Oxidation & Corrosion: Proper handling minimizes exposure to moisture and contaminants that degrade board lifespan.

- Reduces Electrostatic Discharge (ESD) Damage: Static discharge can permanently damage sensitive components if not properly managed.

- Eliminates Flux Residue Risks: Residual flux left behind after soldering can cause short circuits or dendritic growth over time.

At IMS, our ESD-safe assembly areas and controlled cleanroom environments protect sensitive electronic components from contamination, ensuring longevity and reliability in every PCB assembly.

5. Supply Chain Integrity & Traceability

The reliability of a high-quality assembled circuit board also depends on the integrity of its components. Counterfeit or substandard parts can compromise electrical performance, durability, and safety.

Essential Supply Chain Considerations:

- Authorized Component Sourcing: Partnering with trusted distributors ensures genuine, high-quality parts.

- Lot Traceability & Documentation: Maintaining detailed records for every component used allows for efficient troubleshooting and compliance tracking.

- Supply Chain Resilience: Having backup suppliers and contingency plans prevents production delays and material shortages. Read our guide on building resilient supply chains in electronics manufacturing.

Our robust supply chain management guarantees that only authentic, high-quality components are used in our PCB assemblies, ensuring performance and reliability.

Choose IMS for High-Reliability PCB Assembly in Canada

Since 2004, IMS Electronics Manufacturing has specialized in high-precision electronic manufacturing services for industries that demand reliability, efficiency, and superior quality. Our deep knowledge of PCB assembly, advanced testing, and supply chain management ensures that every assembled circuit board we craft meets the highest standards of durability and performance.

Why Partner with IMS?

✓ ISO-certified processes for consistent quality control.

✓ State-of-the-art SMT and through-hole assembly for precision manufacturing.

✓ Comprehensive testing protocols to eliminate defects before shipping.

✓ Strict material traceability and counterfeit prevention for quality assurance.

Are you getting what you expect from your manufacturing partner? We set new industry benchmarks by offering expansive PCB manufacturing options and superior care. We’re not an average contract electronics manufacturer; we’re your strategic partner.

Get Reliable PCB Assembly with IMS

Stop risking PCB failures that lead to downtime and lost revenue. When failure isn’t an option, trust IMS Electronics Manufacturing for high-quality assembled circuit boards built to your industry’s highest standards.

If you’re seeking a reliable manufacturing partner, let’s talk today. Contact IMS to discuss your next PCB assembly project and experience manufacturing done right.