Circuit Board Assembly

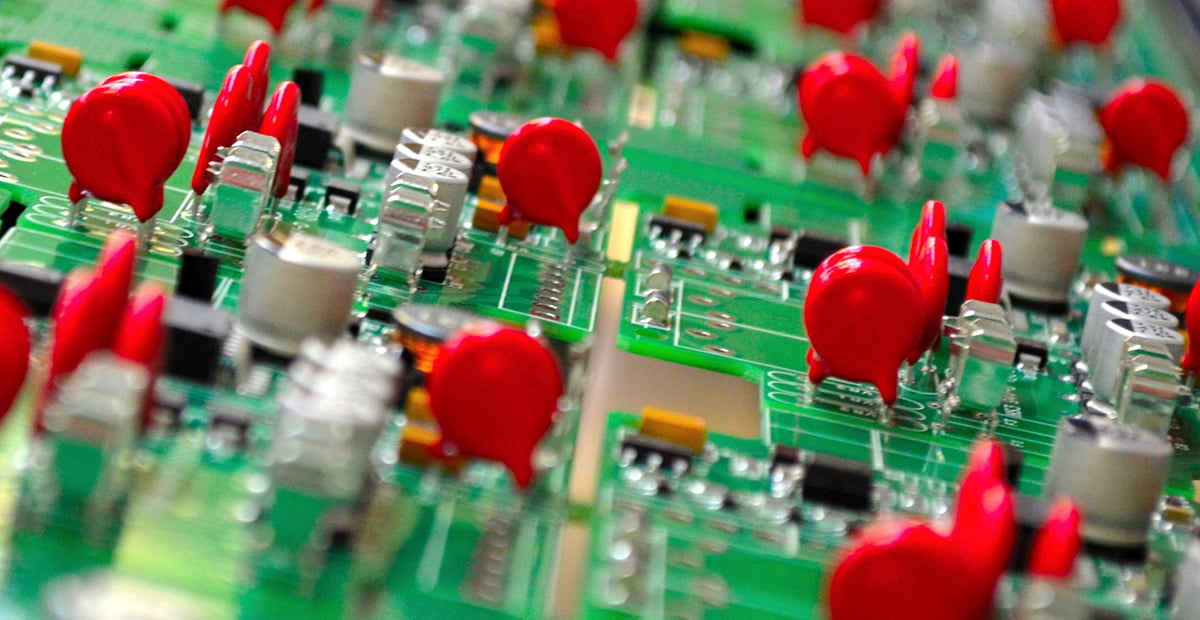

We specialize in assembling circuit boards that power sectors such as marine, military, petroleum, security, telecommunications, transportation, and more. Our expertise ensures your projects move smoothly from prototype to full production with an unmatched level of precision.

IMS combines decades of experience and a commitment to the latest technology to meet each customer’s unique needs, ensuring the highest quality in every build.

From Concept to Completion

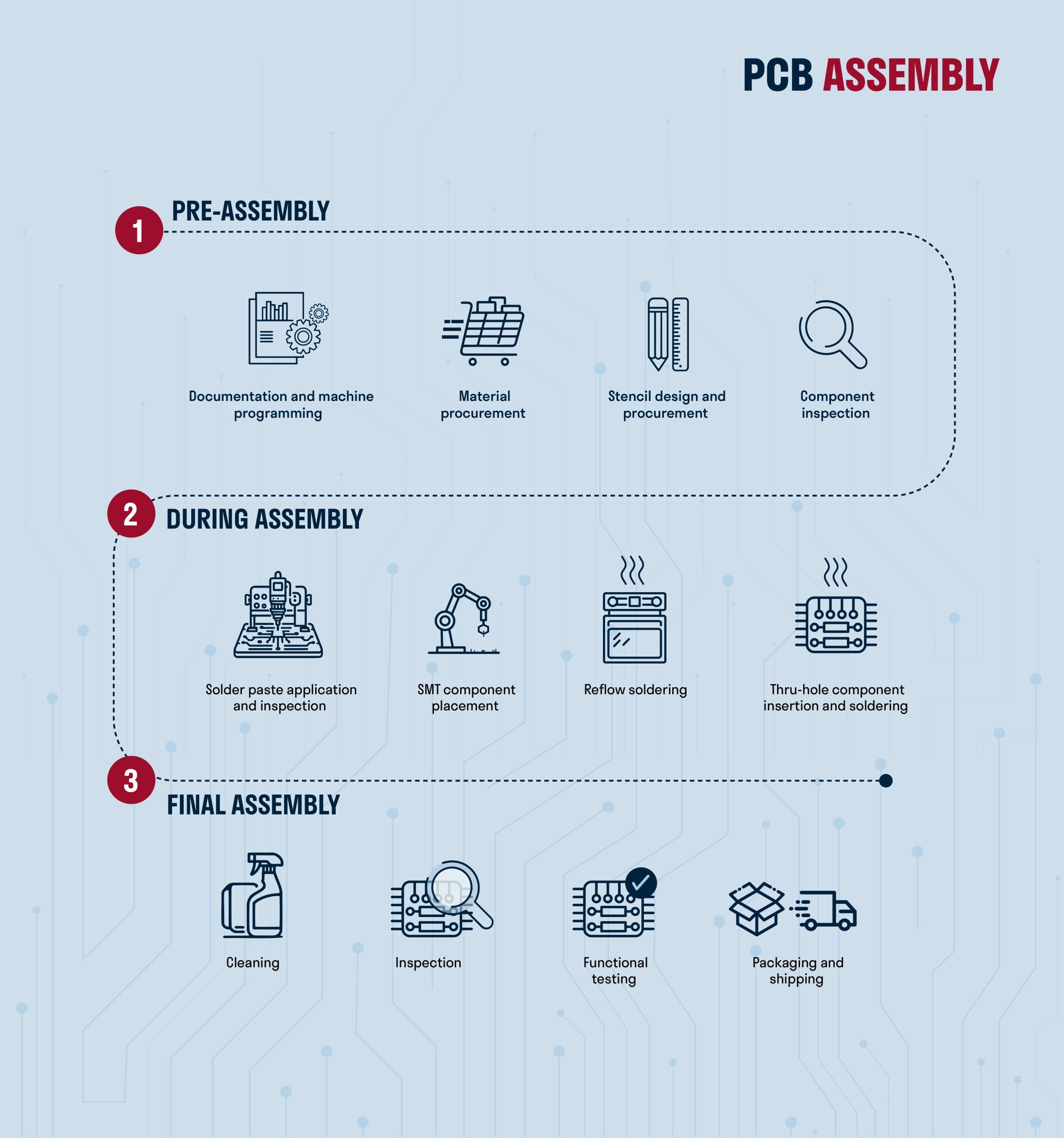

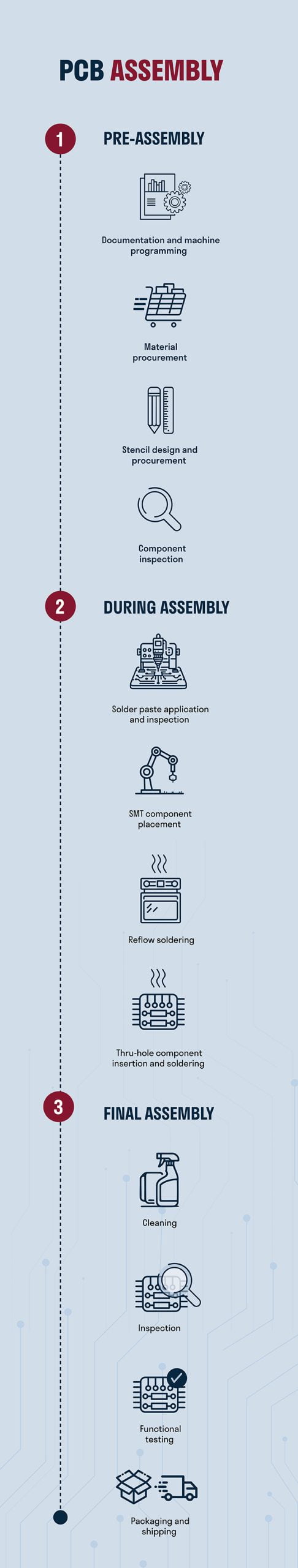

Building a circuit board is like putting together a puzzle of electronic parts. This process has three distinct stages:

IMS Is Where Precision Meets Possibility

We do more than just put together circuit boards – we fuel innovation with our expertise, cutting-edge tools, and a focus on precision. This dedication makes us a top choice for circuit board assembly in North America.

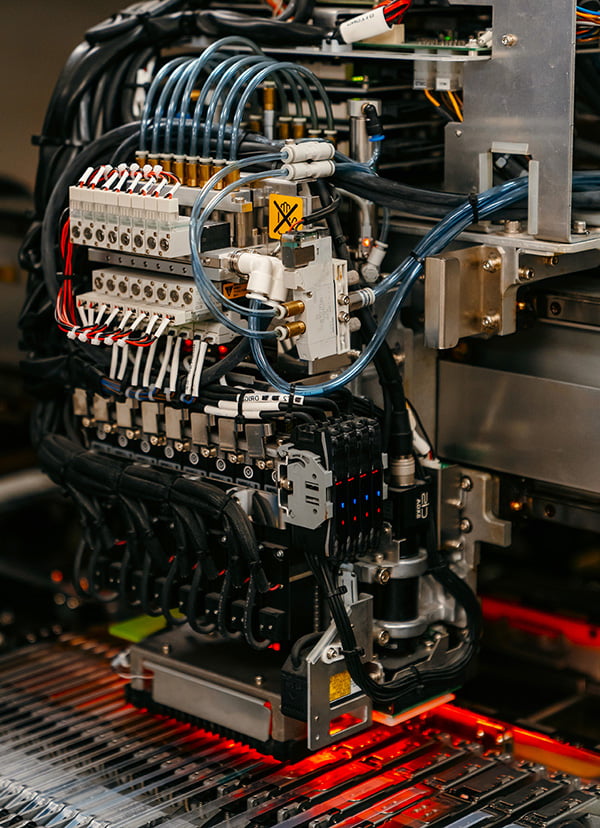

Surface Mount Technology

Our high-speed, fully automated SMT lines are fast and precise, placing up to 120,000 parts per hour with ultimate accuracy.

Equipped with in-line Solder Paste Inspection (SPI) and Automated Optical Inspection (AOI) machines, alongside Glenbrook X-Ray and Vi-5K 3D AOI technology, we ensure every board meets our ultimate standards.

IMS’s sophisticated approach gives your project a significant edge, enabling solutions that are innovative and built to last.

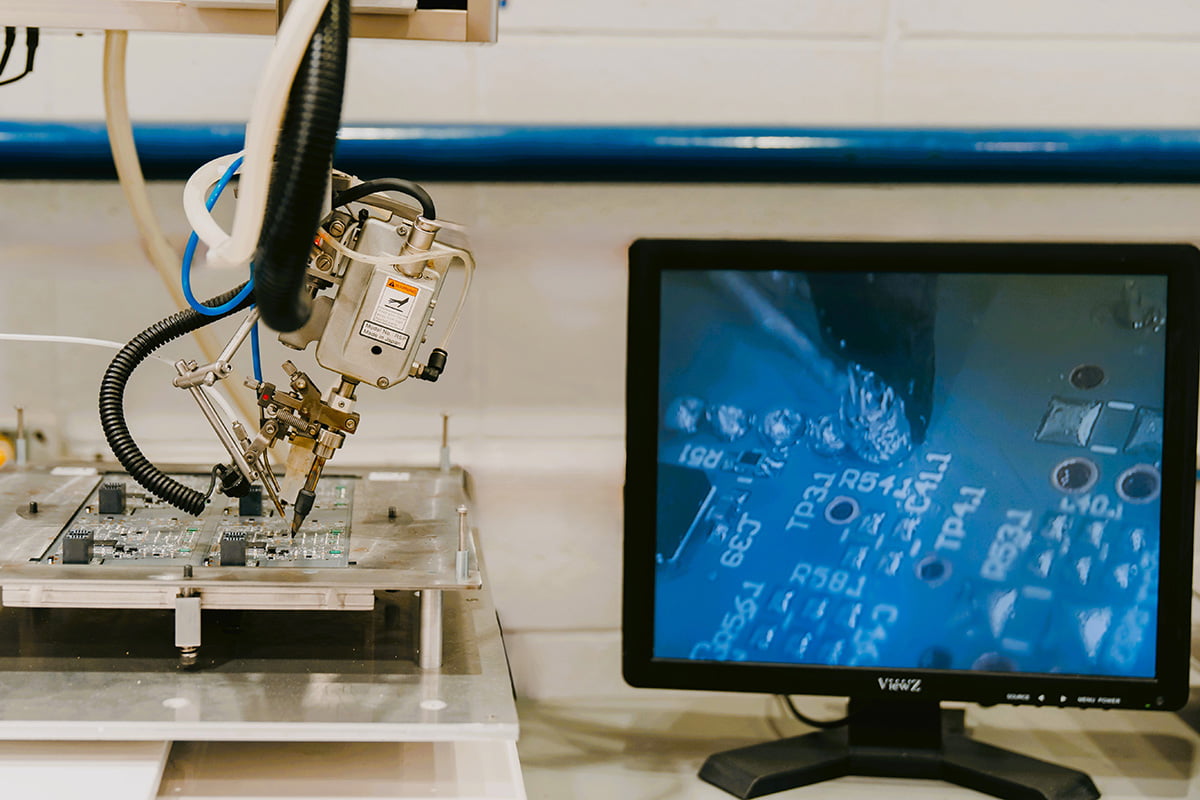

Thru-Hole and Final Assembly

When it comes to final assembly, we focus on detail and durability with careful hand soldering, precise de-panelization, and pemming to prepare the boards. Then, our Applo Seiko Robotic Arms take over for pinpoint soldering accuracy. Our 450 Ecoselect Wave applies fine-point selective soldering for even more detailed work.

To ensure cleanliness, the Aqueous Technology Board washer removes any contaminants. Finally, for any necessary rework, our Ersa BGA/Fine Pitch rework station is ready, ensuring every board is assembled to perfection.

Ensuring Excellence: Our Testing and Troubleshooting Process

At IMS, we deliver only the highest-caliber circuit boards. Our comprehensive testing and troubleshooting procedures are central to our quality assurance.