When it comes to manufacturing, selecting the right partner can make or break your project. At Innovative Manufacturing Source (IMS), we pride ourselves on being more than just a supplier—we’re a solutions-driven partner with the technical expertise, versatility, and customer focus to bring your vision to life.

Here’s why IMS stands out:

1. Proven Expertise in Both Sheet Metal and Electronics Manufacturing

IMS is uniquely positioned as a dual-specialist in custom sheet metal fabrication and electronic manufacturing services (EMS). Whether you’re developing complex enclosures or precision PCB assemblies, our integrated capabilities provide seamless production from design to delivery. This one-stop-shop model reduces vendor coordination challenges and allows for better alignment between mechanical and electronic requirements. Read more

2. Material Selection Backed by Practical Insight

Material choice significantly affects product longevity, strength, and cost. While IMS doesn’t specify materials on behalf of clients, our experienced technicians can offer valuable recommendations based on factors like durability, weight, corrosion resistance, and aesthetics. We help clients make informed decisions that suit their application and budget—ensuring the final product meets both performance and cost expectations.

3. High Standards for Product Reliability and Quality

From soldering precision to component placement, IMS follows stringent quality control measures for consistent, high-performing assemblies. We use automated optical inspection (AOI), conformal coating, and robust in-circuit testing protocols. These practices minimize risk, increase yield, and give clients confidence in the reliability of every board delivered. Learn about our QA approach

4. Custom Fabrication That Matches Your Application

Not all projects benefit from standard fabrication. IMS offers tailored sheet metal designs that meet the specific form, function, and fit required by your application. Our custom fabrication capabilities are ideal for clients who require specialized enclosures, heat dissipation features, or integration with unique electronic designs.

5. Cost-Efficient and Scalable Manufacturing Solutions

Outsourcing to IMS can reduce overhead, improve turnaround, and free up internal resources—whether for full contract manufacturing or subassembly. With scalable infrastructure and flexible service models, we support your growth from prototype to full production.

6. Transparent, Client-Focused Collaboration

IMS believes in clear communication and tailored solutions. We provide ongoing engineering support, detailed documentation, and project transparency to build long-term trust. Our collaborative approach means you’re never left in the dark—we treat your project as if it were our own. Explore collaboration tips

7. Commitment to Efficiency Without Compromising Quality

If your current supplier is missing deadlines, lacking consistency, or inflating costs, it may be time to switch. IMS offers streamlined workflows that prevent inefficiencies and reduce hidden expenses. We proactively identify cost drivers and eliminate unnecessary process steps without compromising quality.

8. Signs of a Trusted Sheet Metal Fabricator

IMS embodies the top qualities of a reliable fabrication partner—ISO-certified processes, in-house capabilities, responsive service, and a proven track record of performance. We invest in continual training, modern equipment, and lean practices to meet evolving customer demands with precision.

9. Strategic Guidance for Smarter Decisions

Choosing between in-house assembly and contract manufacturing can be complex. IMS helps you weigh the trade-offs between control, cost, and scalability, offering strategic advice backed by real-world experience. Our team can help you optimize sourcing strategies and production planning for long-term success.

10. Built for the Real World

We understand that every project comes with unique challenges—tight timelines, budget constraints, or evolving design specs. IMS is built to respond quickly and flexibly without compromising quality. From first prototype to full rollout, we’re here to help you succeed.

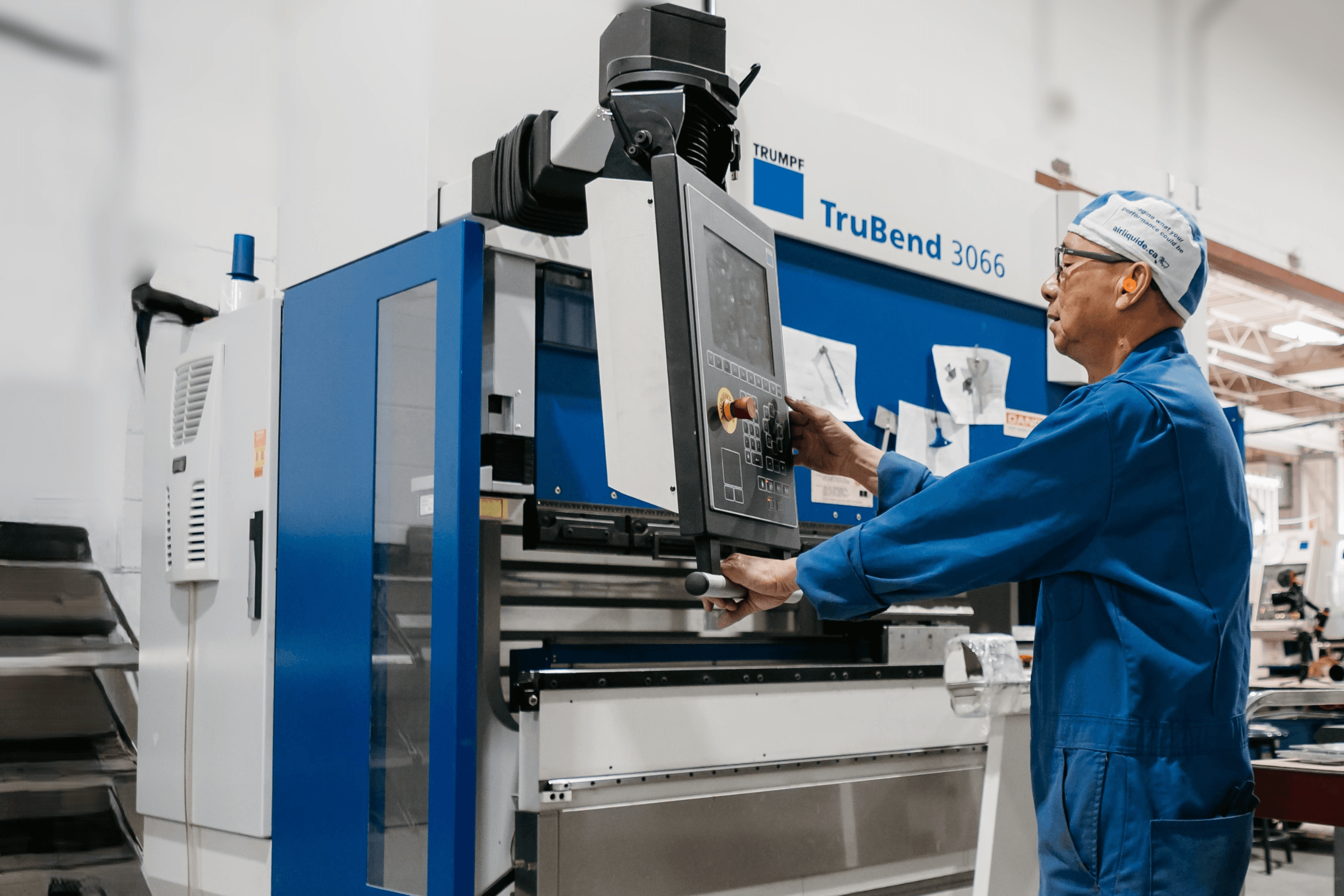

11. In-Depth Knowledge of Fabrication Processes

IMS leverages deep industry knowledge in both traditional and advanced sheet metal fabrication methods. From laser cutting and CNC punching to bending and finishing, our capabilities ensure precision and repeatability. We also help clients understand the benefits and limitations of fabrication techniques for smarter decision-making.

12. Design Optimization for Manufacturability

Our technicians work closely with clients in the early design phase to offer insights that improve manufacturability, reduce unnecessary complexity, and cut production costs. We apply Design for Manufacturing (DFM) principles to help streamline the process and enhance lead times—all while keeping the final decision in the client’s hands.

13. Quality Control That Protects Your Reputation

Low-quality boards or enclosures can cause field failures, warranty claims, and customer dissatisfaction. IMS prevents this by applying strict quality assurance protocols at every step of the production cycle—from component sourcing to final inspection.

14. Commitment to Sustainability

IMS integrates environmentally responsible practices throughout the manufacturing process—from using recyclable materials and reducing waste to investing in energy-efficient equipment. We help clients align their production with sustainability goals without sacrificing performance. See our sustainability approach

15. Serving Diverse Industries with Versatility

IMS supports clients across a wide range of sectors, including telecom, medical, industrial, energy, defense, and transportation. Our diverse experience enables us to handle varying compliance requirements, standards, and design constraints.

Ready to Start?

Whether you’re looking to simplify your supply chain, scale production, improve quality, or strengthen sustainability, IMS is equipped to deliver. Let’s build something great together. Contact us today to get started.