Imagine the intricate circuitry inside your smartphone or the complex systems powering industrial machinery. At the heart of these technologies are two critical processes: PCB (Printed Circuit Board) assembly and box build assembly.

In this article, we’ll peel back the layers of both PCB and box build assembly, helping you understand how each process contributes to the electronics we rely on every day. By the end, you’ll grasp the distinctions between the two and also appreciate the vital role each plays in the journey from concept to final product.

What Is PCB Assembly?

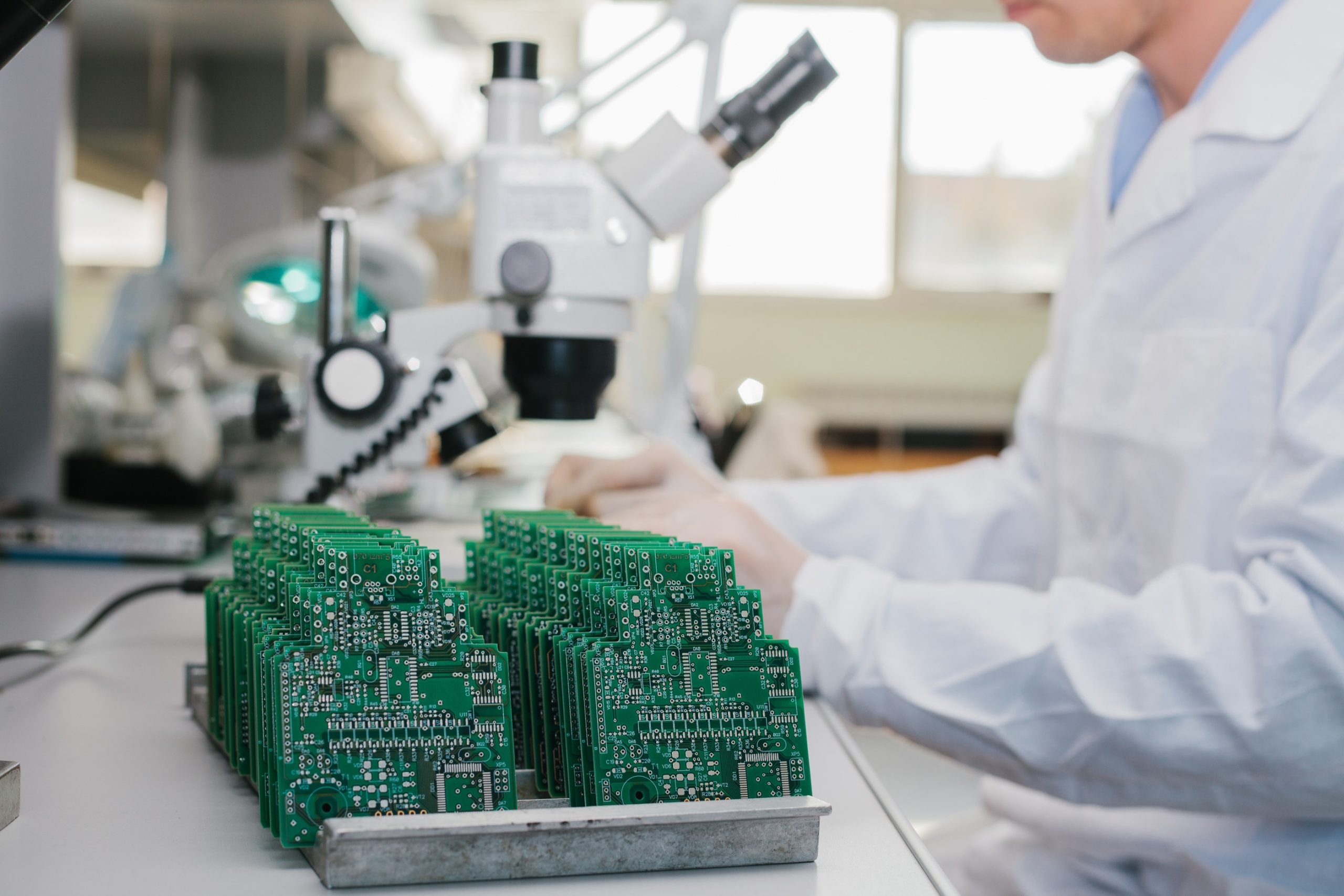

At the heart of every electronic device is a Printed Circuit Board (PCB)—the nerve center where components work together to bring technology to life. But how do these components find their way onto the board? That’s where PCB assembly comes in.

In PCB assembly, electronic components are either mounted directly onto the surface of a printed circuit board using Surface Mount Technology (SMT) or inserted through the PCB using Through-Hole Technology (THT), depending on the design and functional requirements.

Here’s a simplified look at the process:

- Soldering: A special solder paste is applied to the PCB, ready to hold components in place.

- Component Placement: Microchips, resistors, and other tiny parts are placed with precision onto the board.

- Reflow Soldering: The PCB passes through a reflow oven, where heat melts the solder paste, bonding components securely.

- Quality Control: Each board is carefully inspected to ensure everything is working perfectly.

Types of Components Involved:

- Active Components: The “brains” of the board, such as transistors and integrated circuits, which manage the flow of electricity.

- Passive Components: Supporting players like resistors and capacitors that don’t need electrical power to function but are vital to performance.

Where Are PCBs Used?

From smartphones to medical devices and automotive systems, PCBs are everywhere. Their precision and reliability make them crucial in a wide range of industries, ensuring that the technology we depend on functions smoothly.

What Is Box Build Assembly?

Think of box build assembly as the final, crucial step in the electronics manufacturing process. It’s where everything comes together to create the finished product. While PCB assembly focuses solely on the circuit board, box build goes beyond by integrating the PCB with other components to form a fully functional device.

Unlike PCB assembly, which is all about putting together the internal brain of a product, box build takes care of the entire system. It involves:

- Wiring and Cable Routing: Connecting wires and cables to ensure power and signals flow correctly through the device.

- Installing PCBs into an Enclosure: Placing the completed circuit board inside a protective casing or housing.

- Adding Mechanical Components: Assembling physical parts such as screws, brackets, or fans to finalize the product.

- Final Testing: Running the complete product through functional tests to ensure everything works seamlessly.

Types of Components Involved:

- Cable Assemblies and Wiring: Ensuring that all the connections inside the product are secure and well-organized.

- Enclosures: Housing the internal components, often requiring custom designs to protect the electronics.

- Power Supplies and Subassemblies: Integrating the power sources and smaller electronic assemblies that bring the whole system to life.

Applications of Box Build Assembly

Box build assembly is essential for products that require more than just a circuit board—it’s about creating fully operational systems. Industries like telecommunications, industrial equipment, and automotive rely on box-build services to produce complex, high-quality products. Whether it’s a data server or an automotive control unit, box build ensures the product is market-ready, both electronically and mechanically.

Main Differences Between PCB and Box Build Assembly

While PCB assembly and box build assembly are both critical in the electronics manufacturing process, they serve distinct roles. Understanding their differences helps companies choose the right approach for their specific product needs.

1. Scope and Complexity

✓ PCB assembly focuses purely on the circuit board—the heart of any electronic device. It involves placing and soldering electronic components onto the PCB.

✓ Box build assembly goes beyond the circuit board, involving the entire system. It encompasses the wiring, enclosure, and mechanical components to deliver a fully functional, market-ready product.

2. Components and Materials

✓ PCB assembly deals primarily with electronic components like resistors, capacitors, and integrated circuits, which are mounted onto the circuit board.

✓ Box build assembly integrates a variety of materials and components—ranging from PCBs and cables to enclosures and mechanical hardware.

3. Testing and Quality Control

✓ PCB assembly focuses on testing the functionality of the circuit board itself. Techniques like automated optical inspection (AOI) and in-circuit testing (ICT) are commonly used to ensure precision.

✓ Box build assembly includes more comprehensive testing at the system level. This testing could involve functional testing, environmental stress tests, and verifying the product’s overall performance once fully assembled.

4. Skills Required

✓ PCB assembly demands highly specialized skills in placing and soldering tiny electronic components with precision.

✓ Box build assembly requires a broader skill set that includes cable management, mechanical assembly, and systems integration, making it more multifaceted.

5. End Product

✓ PCB assembly results in the core circuit board that powers the device, but it’s typically not the finished product.

✓ Box build assembly delivers the complete end product ready for consumer or industrial use.

When Do You Need PCB Assembly vs. Box Build Assembly?

Choosing between PCB Assembly and Box Build Assembly depends on your product’s complexity and where you are in the production cycle. Each process serves different stages of product development, and understanding when to use each can optimize efficiency, cost, and time-to-market.

When to Choose PCB Assembly:

- Prototyping and Early Development. If you’re in the early stages of creating an electronic product and need to focus on functionality and circuit design, PCB assembly is where you’ll begin. It’s the essential first step in powering your device, ensuring the electronic components work as intended.

- Basic Circuit Needs. If your product is primarily about delivering electronic functions without the need for enclosures or mechanical parts (such as a circuit board for an internal system), PCB assembly is likely sufficient.

When to Choose Box Build Assembly:

- Ready-to-Ship Products. If you’re nearing the final stages and your product requires housing, wiring, and mechanical components, box-build assembly is necessary. This process brings the product to a fully finished state, ready to ship and use.

- Complex Systems Integration. Products like IoT devices, industrial equipment, or consumer electronics often require a complete system where the PCB, cables, power supplies, and enclosures all come together. Box build assembly offers the full integration needed to get these products into the hands of consumers.

Some Industries Need Both PCB and Box Build Assembly

Many industries require both processes to get their products market-ready. For instance:

→ Medical Devices. PCB assembly is used to create the device’s electronic brain, while box build assembly adds the enclosures, wiring, and final integration for a functional medical device.

→ Automotive Electronics. The PCB powers various automotive systems, but full assembly into durable, vibration-resistant enclosures happens during box build.

→ Aerospace and Defense. PCB assembly is critical for avionics and defense electronics, powering systems like navigation and communication, while box-build assembly ensures these sensitive electronics are integrated into rugged, environmentally shielded enclosures built to withstand extreme conditions.

→ Oil and Gas. In the harsh environments of oil and gas operations, PCB assembly drives control systems for monitoring and data acquisition, while box build assembly protects these systems in explosion-proof, weather-resistant housings to ensure safety and reliability in the field.

By understanding your product’s requirements and its stage in development, you can decide when to use PCB assembly alone or combine it with box-build services to create a complete, ready-to-use product.

The Role of IMS in PCB and Box Build Assembly

At IMS, precision and quality are the cornerstones of both PCB assembly and box build assembly services. We combine advanced technology with skilled craftsmanship to deliver high-performance products across a range of industries.

PCB Assembly Expertise

IMS specializes in Surface Mount Technology (SMT) and Through-Hole Technology (THT), ensuring flawless component placement and soldering. With rigorous testing, we guarantee each PCB meets the highest standards of reliability and functionality.

Turnkey Box Build Solutions

Our box-build services go beyond PCB integration. We offer complete solutions, including custom enclosures designed and fabricated at our in-house metal shop. Our team of designers and metal fabricators works closely with you to create enclosures that perfectly house the PCBs and cables produced in our electronics shop. Whether you need small-scale enclosures or large housing units for industrial equipment, we ensure seamless electrical and mechanical integration across every build. From telecom to medical devices and industrial equipment, IMS delivers fully integrated products ready for the market—all under one roof.

Commitment to Quality

Quality is in everything we do, from PCB to box build. With ISO 9001:2015 and IPC certifications, IMS Electronics Manufacturing ensures your products meet industry standards and perform flawlessly, backed by thorough end-to-end testing.

Elevate Your Manufacturing with IMS Electronics

Choosing the right electronics manufacturing partner can make all the difference between an average product and one that truly stands out. Whether you need precise PCB assembly or comprehensive box-build solutions, IMS brings expertise, cutting-edge technology, and a relentless commitment to quality.

After leading the industry for more than 20 years, we understand the complexities of modern electronics manufacturing and are here to streamline your journey from prototype to final product. With a collaborative, customer-first approach, IMS helps you achieve faster time-to-market, scalability, and the reliability your customers expect.

Ready to transform your manufacturing process? Partner with IMS and let us turn your vision into reality. Contact us today to learn how we can support your next big project!