Choosing the right manufacturing company in Canada can significantly impact your product’s quality, cost, and production efficiency. Whether you need electronics manufacturing, sheet metal fabrication, or box build assembly, selecting the right partner ensures that your project stays on time, on budget, and meets industry-specific quality standards.

With so many options available, how do you determine which Canadian manufacturing company is the best fit for your business? This guide outlines key factors to consider, questions to ask, and red flags to watch out for when selecting a trusted manufacturing partner.

1. Industry Expertise & Capabilities

Not all manufacturing companies in Canada offer the same level of expertise or specialization in the same industries. Before choosing a partner, consider:

- Does the company have experience in your industry? Manufacturers specializing in electronics, aerospace, automotive, or medical devices will have capabilities different from those of general-purpose fabricators.

- Do they provide the exact services you need? Check whether the company specializes in PCB assembly, sheet metal fabrication, box builds, wire harnessing, or any other processes essential to your project.

- Can they scale production? Whether you need low-volume prototypes or high-volume production, your manufacturing partner should be able to accommodate your growth.

Questions to Ask:

❓ What industries do you specialize in?

❓ Do you provide both prototyping and full-scale production?

❓ Can you handle custom manufacturing requests?

2. Quality Standards & Certifications

A manufacturer’s commitment to quality directly affects your product’s reliability. Look for certifications and standards that demonstrate adherence to industry best practices:

→ ISO 9001: Ensures quality management systems are in place.

→ IPC Class II & Class III: Essential standards for electronics assembly and wire harness manufacturing.

→ AS9100: Required for aerospace manufacturing.

→ CSA, UL & ETL Compliance: Important for electrical and safety certifications.

Questions to Ask:

❓ What certifications do you hold?

❓ How do you ensure product quality and consistency?

❓ What quality assurance/quality control measures do you follow?

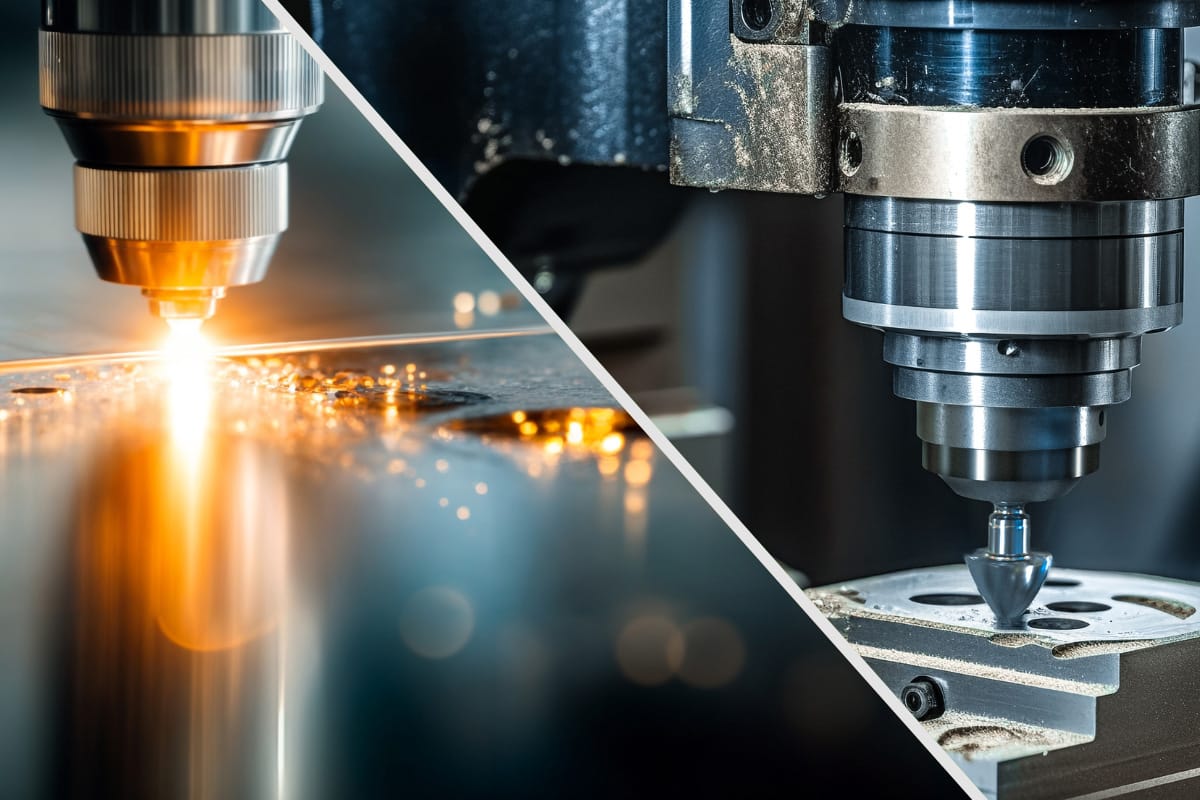

3. Technology & Equipment

The right manufacturing partner should utilize state-of-the-art technology and modern production processes to ensure efficiency, precision, and cost control.

- Advanced CNC machining and laser cutting for sheet metal fabrication.

- Automated assembly lines for PCB and electronics manufacturing.

- Testing & inspection equipment to maintain high-quality standards.

- AI-driven production optimization for improved efficiency.

Questions to Ask:

❓ What manufacturing technologies do you use?

❓ Do you offer automated production and quality testing?

❓ How do you stay up-to-date with industry advancements?

4. Supply Chain & Material Sourcing

A strong supply chain ensures timely production and cost-effective materials. Ask about:

- Where they source materials from—local suppliers vs. international.

- Lead times and availability of key components.

- Contingency planning for supply chain disruptions.

Questions to Ask:

❓ Do you have established supplier relationships?

❓ How do you handle supply chain challenges?

❓ Can you source sustainable or specialized materials?

5. Customization & Engineering Support

Manufacturers that provide design assistance, engineering support, and customization options can save you time and money in the long run.

- Custom fabrication options for specialized components.

- Value-added engineering services to refine product designs.

- Prototyping & Design-for-Manufacturability (DFM) support.

Read IMS’ complete guide to Design for Manufacturability: Best Practices & Key Considerations.

Questions to Ask:

❓ Can you assist with design and prototyping?

❓ Do you offer DFM analysis to optimize production?

❓ What customization capabilities do you have?

6. Lead Times & Production Turnaround

Manufacturing delays can disrupt your supply chain and increase costs. A reliable partner should provide realistic timelines and consistent production scheduling.

- Ask about typical lead times for prototypes and mass production.

- Ensure they have the capacity to meet your deadlines.

- Look for transparent scheduling processes.

Questions to Ask:

❓ What is your typical lead time for production?

❓ How do you handle rush orders or fluctuating demand?

❓ Can you scale production quickly if needed?

7. Pricing & Cost Transparency

The lowest price isn’t always the best choice! A quality manufacturer provides transparent pricing, cost breakdowns, and no hidden fees.

- Total cost of ownership (TCO): Look beyond per-unit costs to include tooling, setup, logistics, and material sourcing.

- Value-added services like engineering support, quality assurance, and supply chain management may justify a higher upfront cost.

- Compare multiple quotes to ensure fair pricing and service value.

Learn more about the Hidden Costs of Poor Quality in Electronics Manufacturing.

Questions to Ask:

❓ What factors influence your pricing structure?

❓ Are there any hidden costs for tooling or setup?

❓ How do you ensure cost efficiency while maintaining quality?

8. Communication & Customer Support

A responsive and transparent manufacturer should keep you informed at every stage of production.

- Dedicated account managers for consistent communication.

- Real-time production tracking and reporting.

- Clear escalation processes for resolving issues quickly.

Questions to Ask:

❓ How do you communicate project updates?

❓ What happens if there is a production issue?

❓ Do you provide ongoing customer support?

Red Flags to Watch For

When evaluating manufacturing companies in Canada, be cautious of:

🚩 Lack of industry certifications: No ISO, IPC, or quality standards.

🚩 Poor supply chain transparency: Unclear material sourcing or unreliable lead times.

🚩 Limited capacity for scaling production: Can’t handle high-volume orders.

🚩 Hidden costs & unclear pricing: Unexpected fees for tooling or setup.

🚩 Weak communication & customer support: Slow response times or lack of updates.

Choose IMS: A Trusted Manufacturing Partner in Canada

IMS Electronics Manufacturing provides high-precision electronics and sheet metal fabrication services tailored to your industry needs. Our ISO-certified facility in Calgary offers:

✓ End-to-end manufacturing solutions—From PCB assembly to full product builds.

✓ Supply chain resilience—Strategic sourcing for stable, cost-effective production.

✓ Quality assurance & traceability—Full process tracking for compliance and reliability.

✓ Responsive customer support—Transparent communication and dedicated service.

✓ Guaranteed craftsmanship—Backed by a one-year warranty for peace of mind with every project.

Our dedicated team ensures smooth production, fast response times, and clear communication because manufacturing should feel effortless, not stressful.

Get Started with IMS Today

Looking for a trusted Canadian manufacturer for your next project? Discover the perks of working with a dedicated partner focused on your success. Contact IMS today to talk about your production needs. Let’s elevate your project together!