For centuries, sheet metal fabrication has been essential in shaping industries—from early construction and infrastructure to today’s advanced uses. Now, it plays a critical role in aerospace, renewable energy, consumer goods, robotics, and medical devices, producing everything from brackets and cable connectors to MRI scanners, surgical implants, and industrial equipment components.

With its versatility, durability, and cost-effectiveness, fabricated sheet metal is the foundation of countless products. But like any manufacturing process, it comes with both advantages and challenges. Whether you’re prototyping a new product, scaling production, or optimizing costs, understanding how to fabricate sheet metal efficiently is key to achieving quality and performance goals.

In this article, we’ll explore the benefits of working with sheet metal, common manufacturing challenges, and how IMS Electronics Manufacturing provides the expertise, technology, and quality assurance needed to meet your production needs.

Benefits of Sheet Metal Fabrication

There are numerous advantages to sheet metal fabrication and forming, making it a preferred choice for industries such as marine, automotive, HVAC, electronics, rail transportation, and agricultural equipment.

Strength & Durability

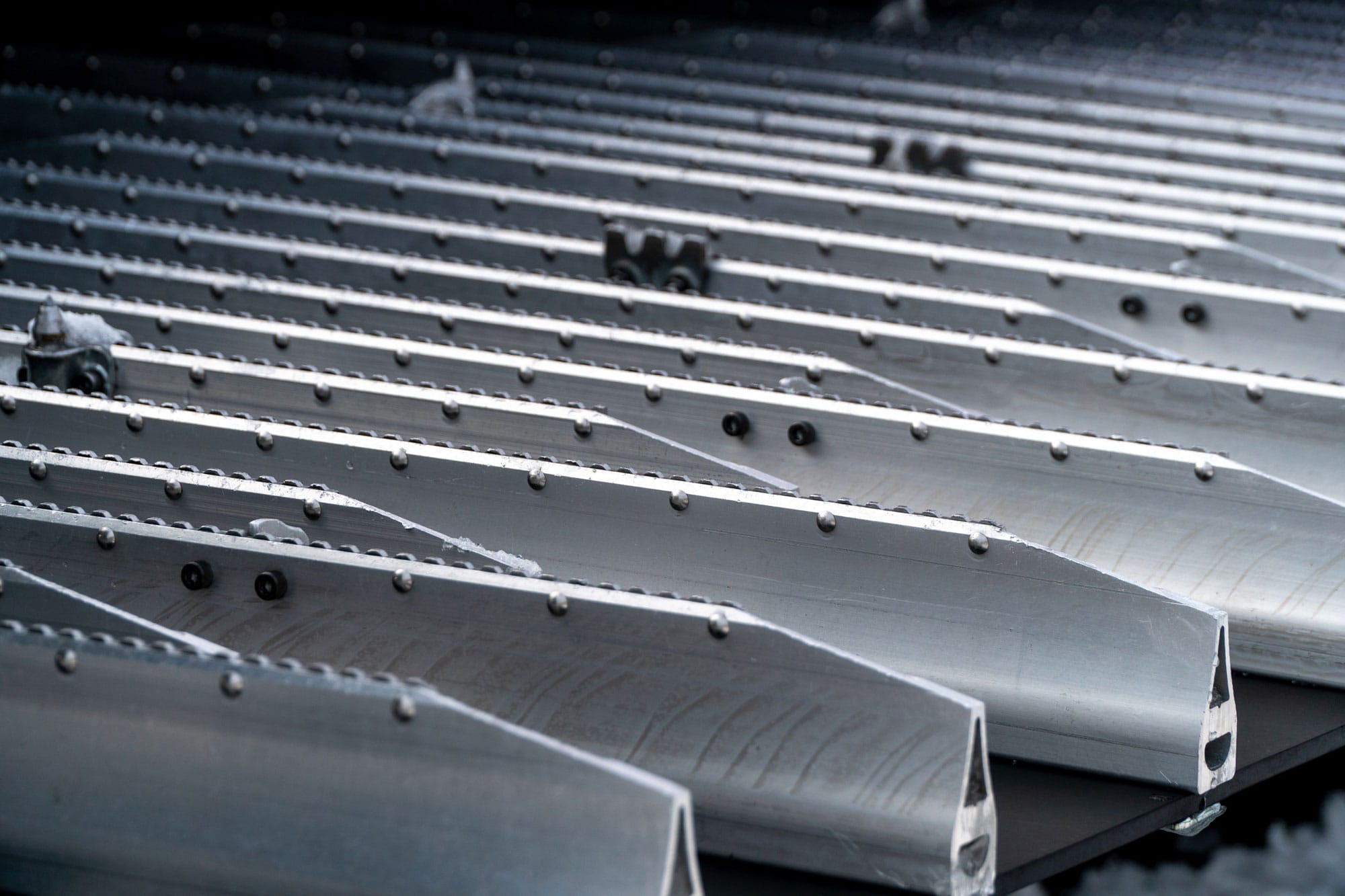

- Fabricated sheet metal is resistant to pressure, corrosion, heat, moisture, and wear, making it ideal for demanding environments.

- Bending increases the metal’s strength, ensuring structural integrity in precision components and high-load applications.

Malleability & Customization

- Sheet metal can be bent, stretched, and shaped without breaking, allowing for complex and highly specialized applications.

- Custom-built designs enable creative freedom in manufacturing, making it an excellent choice for unique components and prototypes.

Replaceability & Modifications

- Individual components can be removed, replaced, or upgraded as part of maintenance or system enhancements, saving time and reducing costs by avoiding complete system overhauls.

- Sheet metal is easily modified to accommodate expansion or design updates without requiring costly retooling.

Sustainability & Recycling

- When no longer needed, sheet metal can be recycled multiple times without degrading in quality. Learn more about sustainable sheet metal manufacturing.

- Scrap metal sheets are often reprocessed into new, high-grade materials, making them an eco-friendly manufacturing choice.

Cost-Effective & High-Capacity Production

- Simple designs have low production costs, making sheet metal fabrication an affordable and scalable manufacturing method.

- Bulk production enables fast distribution while maintaining cost efficiency.

- A variety of fabrication techniques allows manufacturers to tailor processes to meet both budget and performance needs.

Lightweight & Aesthetic Appeal

- Sheet metal is lightweight yet highly durable, making it ideal for applications where weight reduction is crucial, such as medical equipment and devices.

- Various finishing options, including painting, polishing, grinding, and sandblasting, provide a sleek, high-quality appearance for consumer and industrial products.

Precision & Accuracy

- High-precision parts are created through stamping, bending, cutting, blanking, shearing, and laser cutting with computerized fabrication machines.

- Advanced techniques allow for the production of complex parts with tight tolerances, making them widely used in construction, healthcare, food and beverage, and telecommunications.

- State-of-the-art equipment and software ensure extreme accuracy with minimal variability.

Prototyping & Speed of Manufacture

- Sheet metal fabrication allows for easy customization, ensuring that prototypes can be quickly adjusted for design improvements.

- Automation and advanced machinery enable high-speed production with consistent accuracy, making it ideal for large-scale manufacturing.

- High-capacity production facilitates fast distribution to broader markets, improving efficiency and optimizing output rates.

With precision-engineered sheet metal fabrication, IMS can help increase your product lifespan, reduce material waste, and optimize production efficiency, ensuring reliable performance for your high-demand industry. Talk to us about your sheet metal fabrication needs today!

Challenges & Considerations of Sheet Metal Fabrication

While sheet metal fabrication offers many benefits, certain design and production challenges should be considered when selecting this manufacturing method. Working with an experienced fabrication partner like IMS can help mitigate these challenges while maximizing efficiency.

Process Limitations & Production Complexity

- Each fabrication technique has constraints, meaning multiple processes may need to be combined. This can extend production timelines but also ensures the highest level of precision.

- Complex bending operations require precise calculations and may involve trial-and-error testing to achieve the correct shape. Partnering with skilled engineers minimizes these inefficiencies.

Cost Considerations

- High initial tooling investment may be required for custom sheet metal fabrication processes, making high-volume production more cost-effective.

- Manual labor can increase costs, especially for intricate designs. Automation helps lower expenses but is most effective for large production runs.

- Complex designs may require secondary operations, increasing production costs. Design optimization at the prototyping stage can help manage expenses. Get design tips for custom sheet metal fabrication projects.

Material Constraints & Design Challenges

- Thickness limitations. Tight bends are often restricted to thinner sheet metals, meaning heavy-load applications may require alternative fabrication methods.

- Consistent thickness is required. Since sheet metal components are typically cut from a single sheet, thickness cannot be varied within a single part.

- Aesthetic appearance. While functional, some sheet metal designs can have a boxy or industrial look. Post-processing techniques like polishing, sandblasting, and coatings enhance visual appeal.

Production Lead Time & Scalability

- Some projects require multiple fabrication steps, which can extend lead times depending on complexity. Advanced automation and in-house capabilities streamline processes for faster turnaround.

- Efficiently scaling production requires careful planning. Working with a sheet metal fabrication expert helps ensure consistent quality and efficient production scaling.

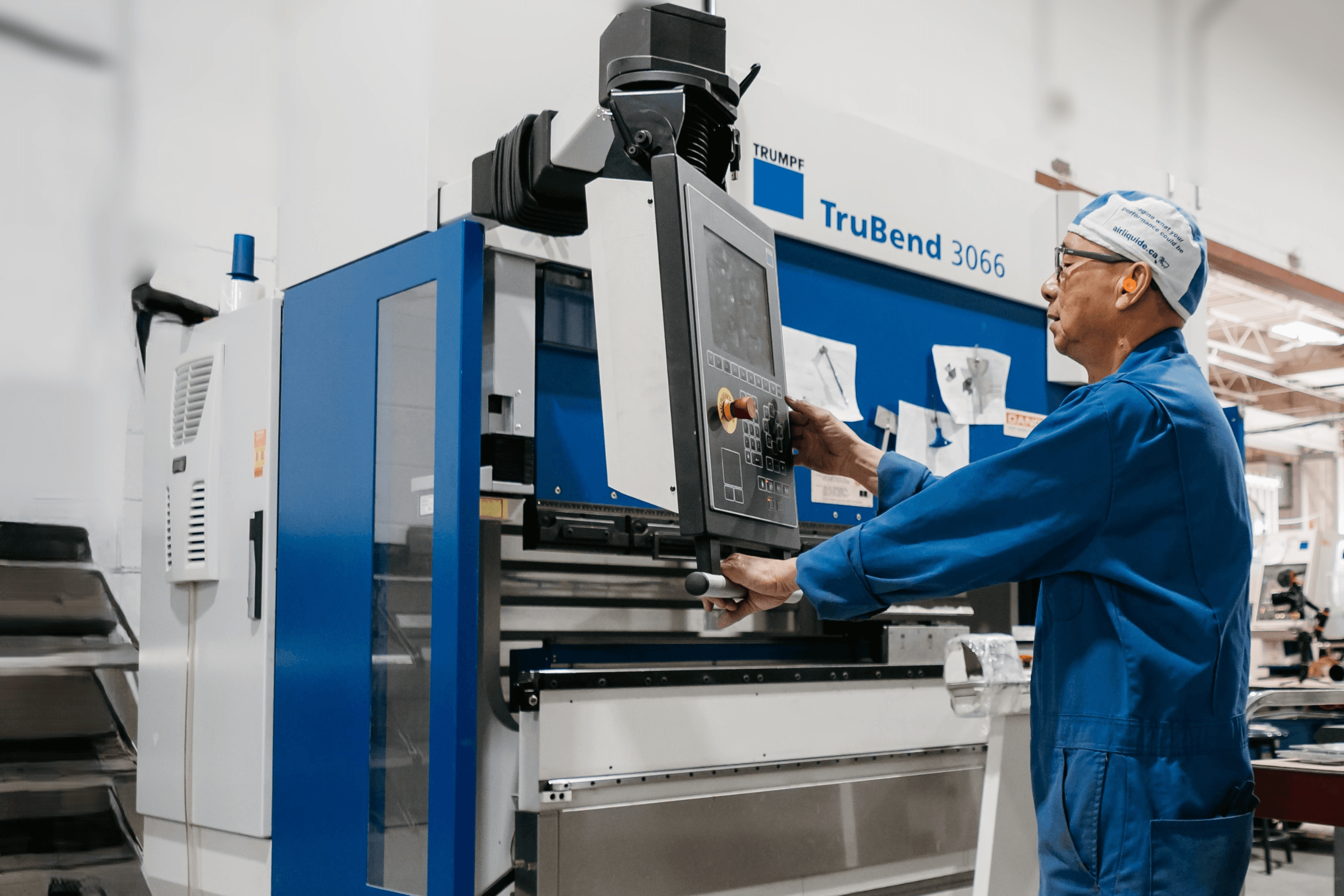

Despite these considerations, advancements in cutting and forming equipment continue to improve accuracy, speed, and cost-efficiency. Complex shapes that were once difficult to manufacture are now achievable with high-precision laser cutting, CNC machining, and automated bending techniques.

Our sheet metal fabrication shop in Calgary specializes in delivering custom, end-to-end manufacturing solutions for businesses across diverse industries. Request a quote today!

Why Choose IMS for Sheet Metal Fabrication in Calgary?

Choosing the right sheet metal fabrication partner can make all the difference in achieving precision, efficiency, and cost-effectiveness. At IMS Electronics Manufacturing, we provide customized solutions for businesses across diverse industries. Our state-of-the-art facility ensures high-quality results through:

Expertise in High-Precision Fabrication

- IMS specializes in complex, tight-tolerance metal components for industries requiring extreme accuracy and reliability.

- Our skilled engineers and technicians ensure consistency and repeatability for every project, from prototyping to full-scale production.

Integrated Manufacturing Services

- Beyond sheet metal fabrication, IMS offers comprehensive manufacturing solutions, including box build assembly, wire harnessing, and finishing services.

- Our in-house capabilities reduce supply chain complexity, improve production speed, and ensure seamless quality control.

Commitment to Quality & Efficiency

- IMS follows strict quality control standards to guarantee flawless, high-performance components.

- Our investment in advanced automation and precision machinery allows us to fabricate sheet metal with minimal waste and maximum efficiency.

With our experience, cutting-edge technology, and dedication to excellence, IMS is your trusted choice for sheet metal fabrication in Canada.

Work with IMS for High-Quality Sheet Metal Fabrication

Your Content Goes HereNeed precision-crafted sheet metal solutions tailored to your industry? IMS Electronics Manufacturing delivers custom solutions, streamlined production, and exceptional quality for your fabrication needs.

Get in touch today to discuss your project and discover how our expertise in sheet metal fabrication can support your business.