Learn

Navigate the Future of Manufacturing with Expert Insights

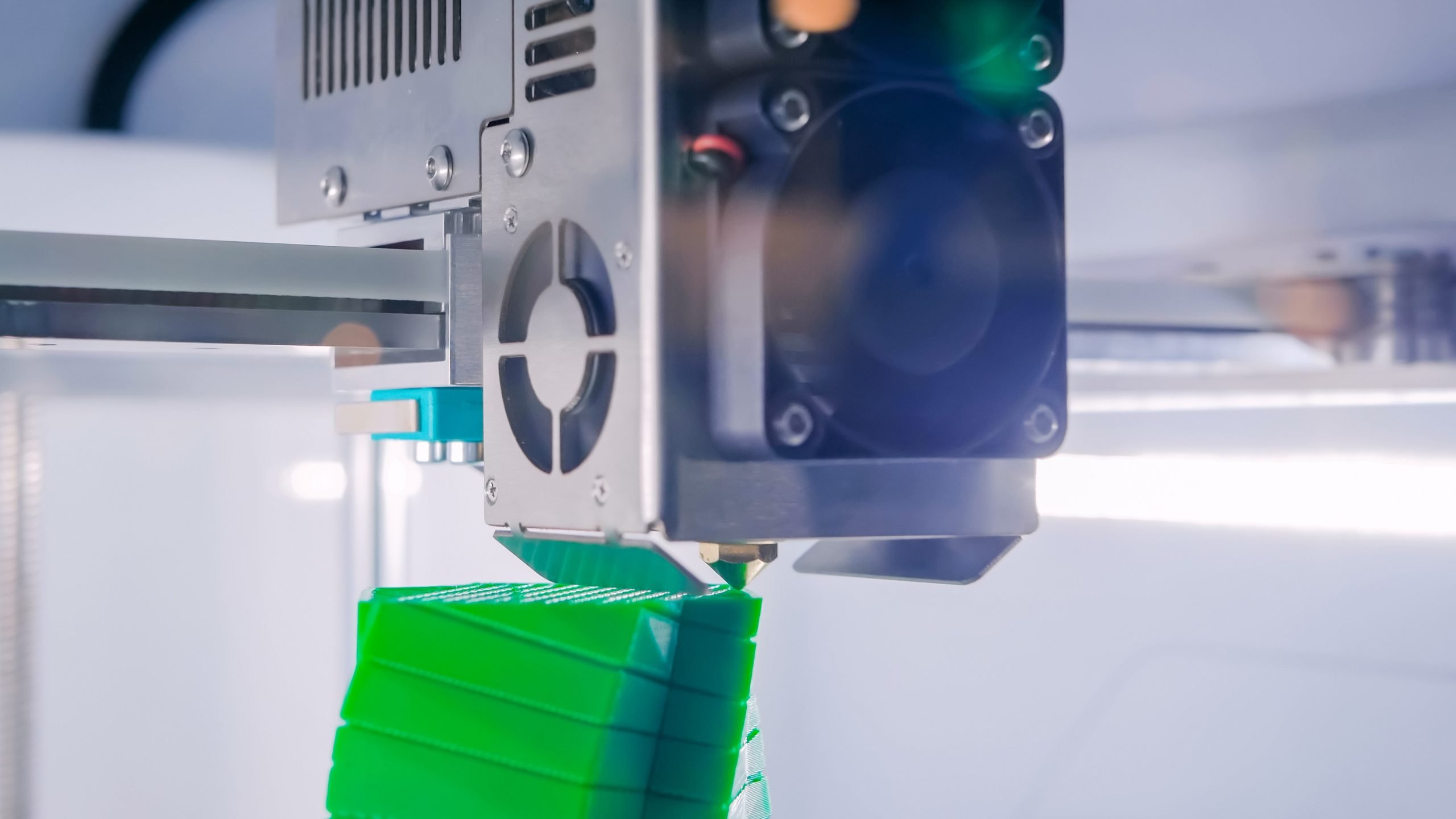

A Step-by-Step Guide to 3D Prototype Printing in Electronics Manufacturing

The rapid pace of innovation in the electronics industry [...]

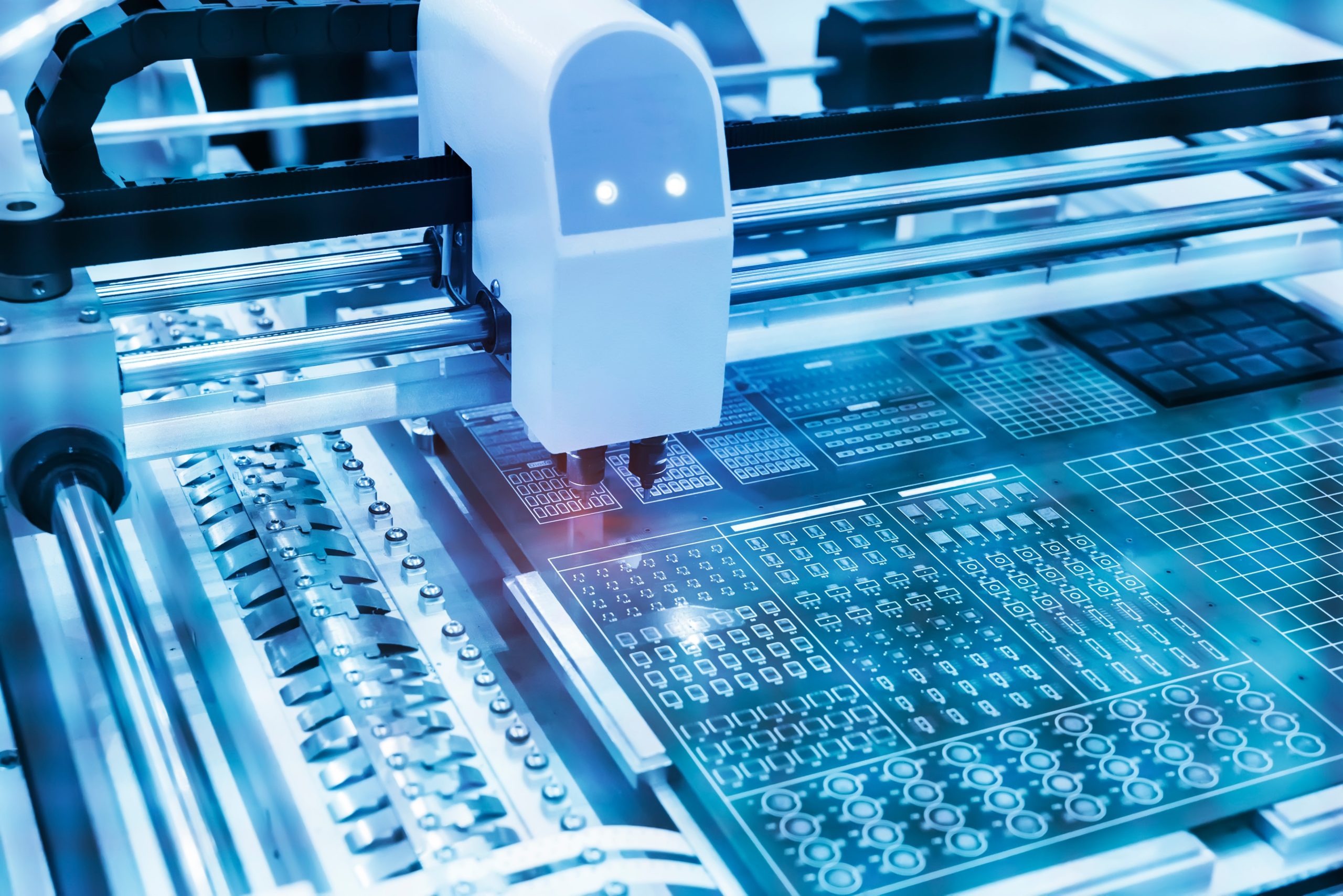

Choosing the Right Circuit Board Assembly Partner

In the fast-paced and highly competitive electronics market, selecting [...]

The Future of Electronic Manufacturing Services: Insights from 20 Years of Industry Leadership

As IMS Electronics Manufacturing celebrates its 20th anniversary, we take [...]

The Role of AI in Revolutionizing Electronics Manufacturing

Today's electronics manufacturing industry faces growing challenges in design, [...]

How Sheet Metal Laser Cutting Services Are Reshaping Industries

In an era where precision, speed, and efficiency are [...]

Navigating the World of Contract Manufacturing

With global markets evolving and product complexities increasing, more businesses [...]

Implementing Lean Methodology – IMS Manufacturing

Manufacturers are always looking for ways to enhance operations, improve [...]

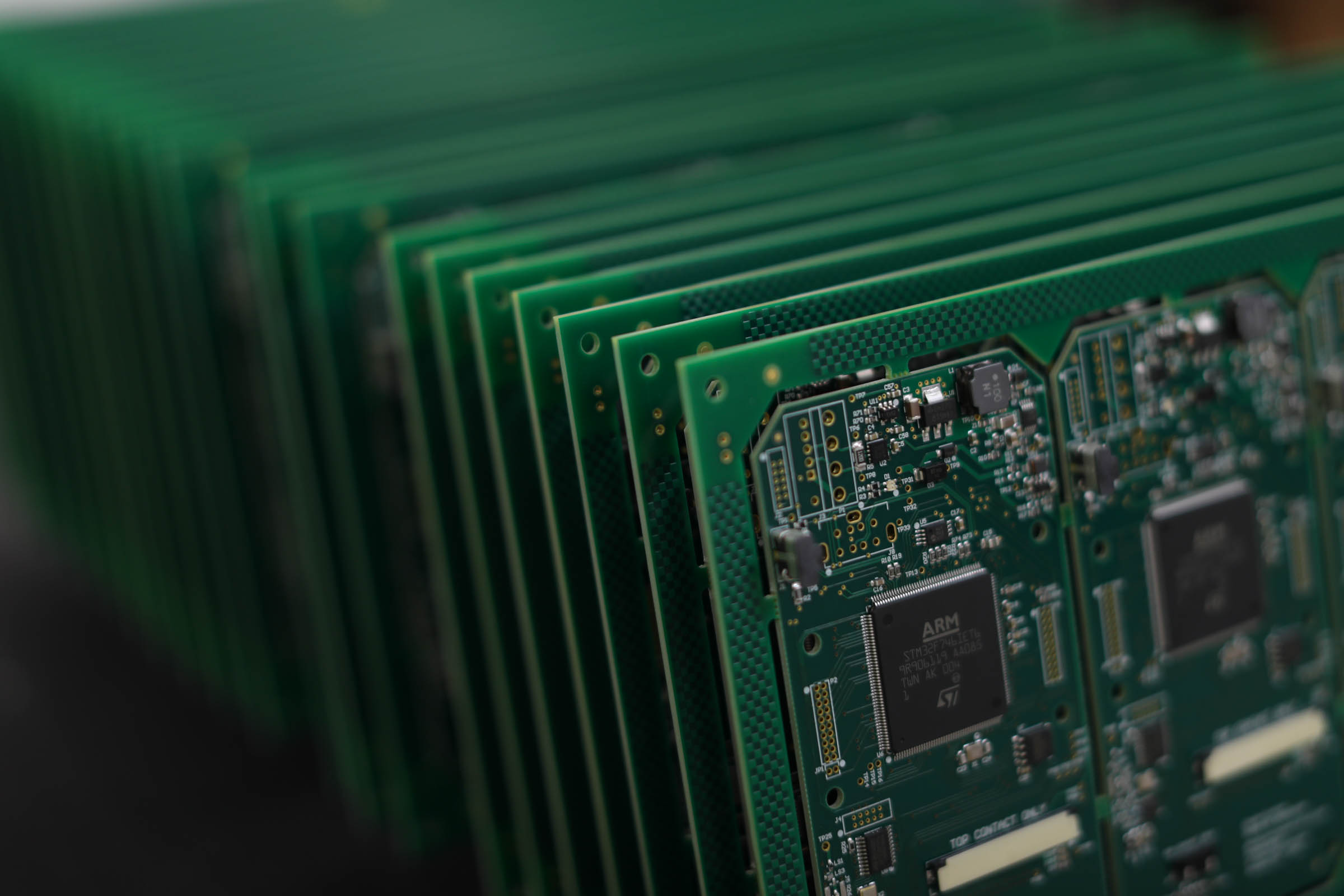

Electronic Manufacturing: The Importance of Production & Process Support

With emerging markets increasing demand and ever-growing numbers of products [...]

Electronic Component Shortage: When Will it Clear up?

The world is currently experiencing a widespread shortage of electronic [...]

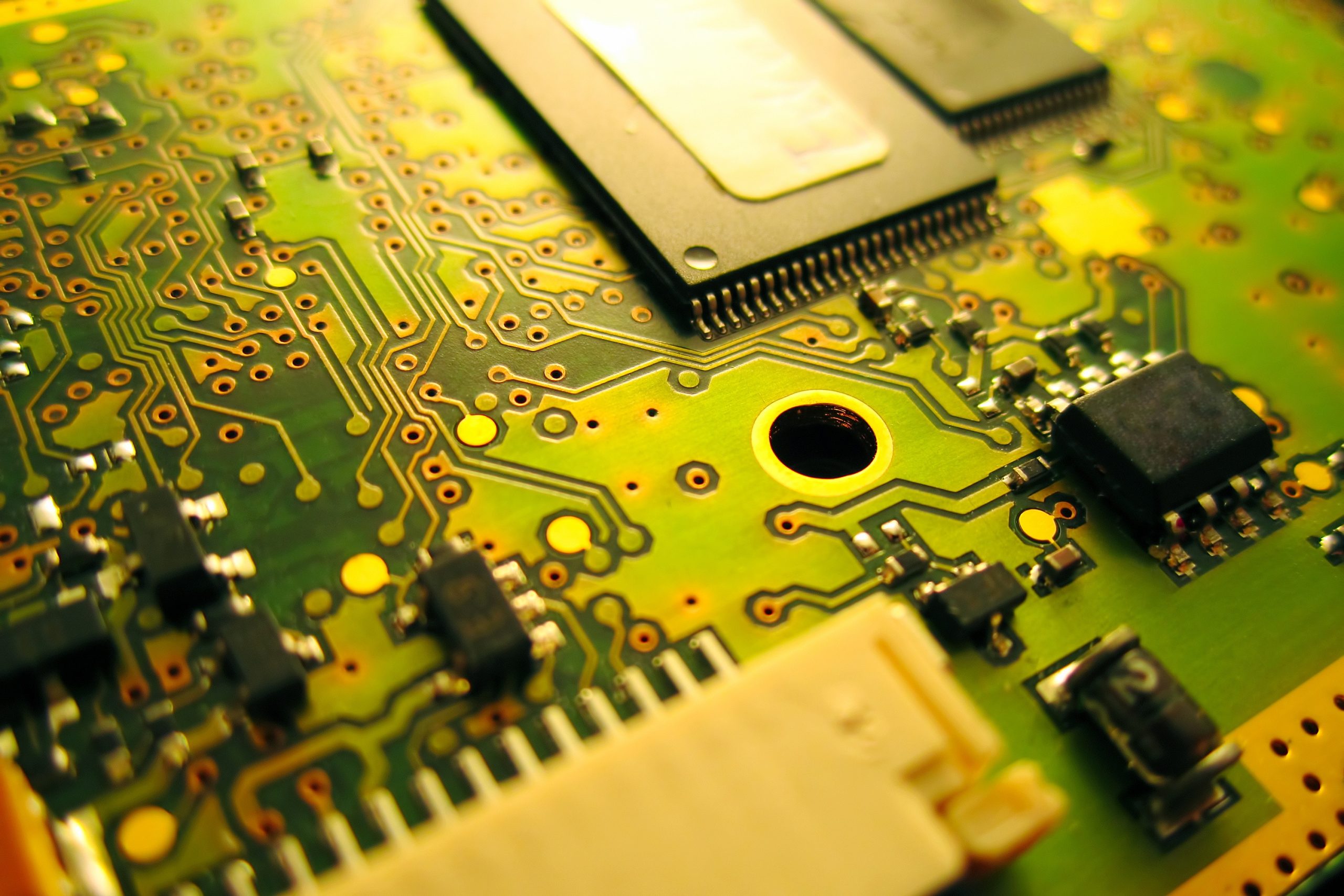

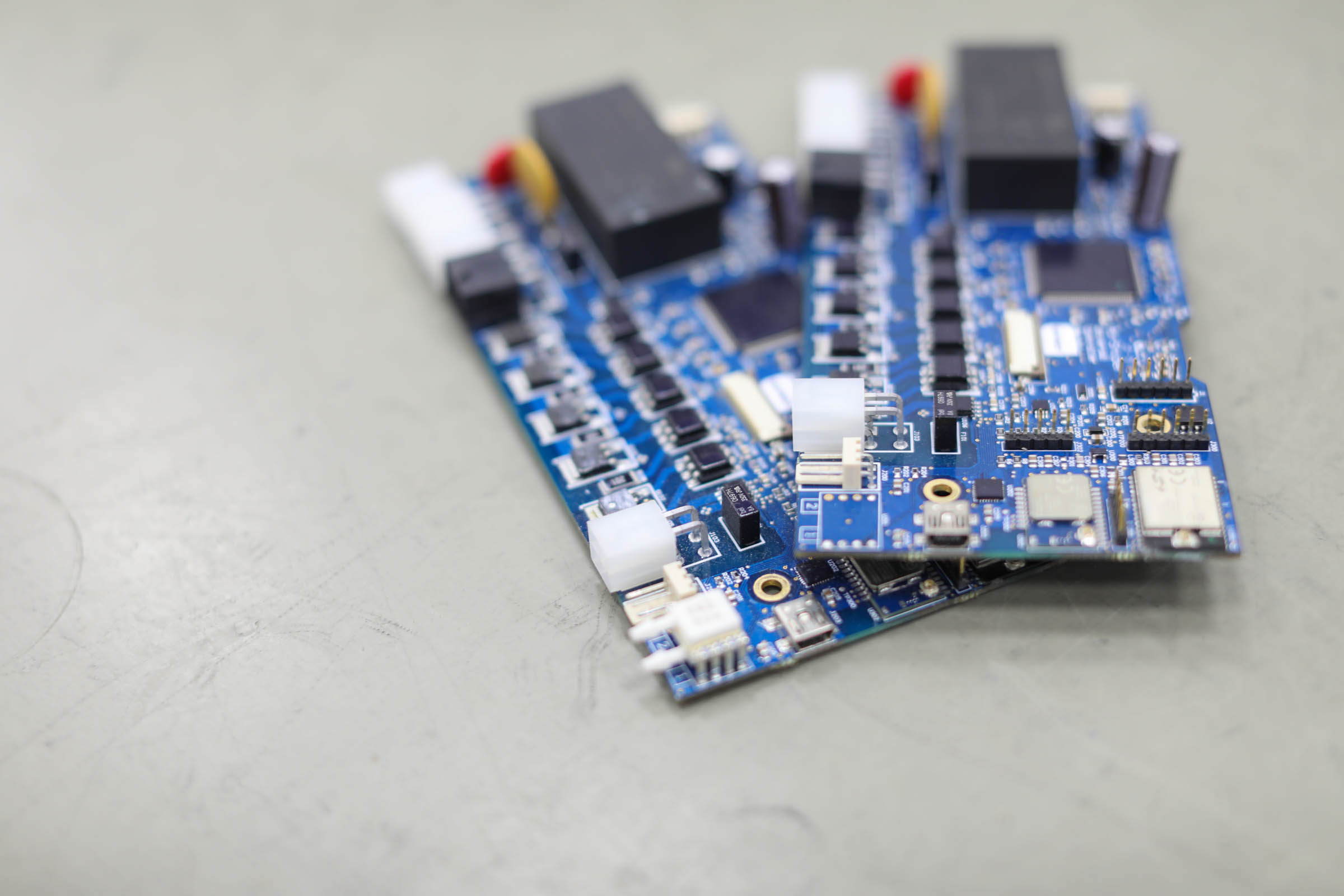

Common Mistakes to Avoid in PCB Design and Assembly

The PCB (printed circuit board) is at the heart of [...]

What’s New in the Electronic Component Market?

There’s an increasing demand for active electronic components due to [...]

Digital Transformation in Manufacturing: Opportunities and Challenges

The advent of new technologies, increasing demand for customization and [...]

IMS Highlights

Technical Glossary: Decoding Manufacturing