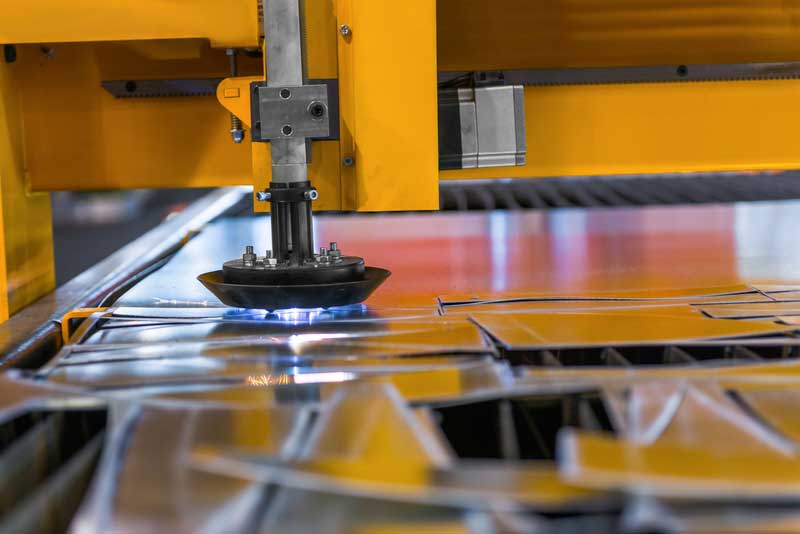

Laser cutting uses advanced technology and advanced techniques; capabilities unavailable with other sheet metal tools/methods. It’s a highly effective process for cutting and forming sheet metal. The laser cutting process involves:

- no physical contact with the sheet metal

- a tiny heat zone resulting in minimal warping

- precise cutting

- complex contour capabilities

- intricate shape capability

- quiet operation

- clean edges

- narrow kerf (the portion of metal that burns away when cut)

What is a laser cutter?

A laser cutter is a prototyping and manufacturing tool used in machine shops, in industries and by makers and artists. Though the laser beam is often used to pierce/cut through materials creating patterns and geometries and etching designs into workpieces, it can also be used to bend 2D metal sheets into complex 3D objects in a process called laser forming. A user designs an idea on the digital software and sends it to the laser cutter. Once the laser cutter receives the file, the machine uses a laser beam to complete the instructions.

What are laser cutting and laser forming?

Laser cutting is the process of cutting a material using a laser beam. This technology uses a concentrated beam of light to cut, and/or etch metals. The cutter is connected to a CNC (computer numerical control) machine and uses smart software that designs a prototype. The design is then translated into a series of instructions to the cutter. Laser forming (bending of metal) is an innovative technology that uses a laser beam to form sheet metal by thermal stresses. The technique consists of traversing a laser beam along a bend line on the material’s surface. Then, the heated portion of the material undergoes an intense cooling (using water or gas) that creates an internal stress field, resulting in a bend along the line of the laser beam traverse. The bend occurs due to the rapid heating and cooling of the metal along the bend line. Laser forming is suited for short and long production runs, eliminating the need for expensive dies and reducing cycle time.

Types of laser cutting:

- Reactive Rutting: As part of the cutting process, high-pressure oxygen is blown into the cut. The oxygen reacts with the heated material (sheet metal), causing it to burn and oxidize while generating additional energy that aids the laser beam.

- Fusion Cutting: Molten material is blown out of the kerf (the portion of metal that burns away when cut) by an inert gas (usually nitrogen), lowering the power needed. The metal is heated until it reaches the melting point, at which time the gas is used to expel it.

- Remote Cutting: When using the remote cutting technique, the material is partially vaporized/ablated, allowing the cutting of thin sheets without the use of gas.

Reasons to choose laser cutting for sheet metal fabrication:

- Affordable prices: Costs for a project are determined by labour, operation and machine costs. Laser cutting is an automated process utilizing computer numeric control (CNC). An operator inputs specifications and the computer does the rest, reducing labour costs. The larger the order, the more cost-efficient laser cutting becomes. Traditional cutting tools use a blade which dulls, requiring cost to repair and maintain. Lasers do not go dull, reducing costs as little repair and maintenance are needed. Laser machine costs are similar to other cutting technology.

- Efficiency and speed: Laser cutters are faster than bladed cutting tools and have 24/7 cutting capability. Once programmed, they work until the order is complete, even if an operator is not present. Traditional designing is time-consuming, especially when the design is small and intricate. A laser cutter is fast and effective.

- Enhanced quality: A laser cutter completes cuts with minimal variation, resulting in a high-quality product with few defects.

- Precision: Laser cutters offer extremely detailed cutting, within the tightest tolerances and with minimal burning. Laser-cut edges and curves are smooth, sharp, and clean with little, if any, burring. Little to no cleanup is involved in the majority of laser-cutting projects.

- Automation allows for greater productivity and superior product quality. Codes are entered into the computer, resulting in pieces that are identical and free of flaws.

- Versatility: No need for an array of different tools as the laser cutter is capable of a variety of functions. Routine tasks/projects, prototypes, industrial orders, delicate designs and larger cutouts are all possible. Lasers can make holes, slots, tabs and other cut fabrications with no interruption of the cutting process. They’re also capable of bending metal.

- Material range: Metals common in industrial processing (steel, aluminum, stainless steel, non-ferrous metal sheets) can be cut and/or bent. Sheet thicknesses from .5 to over 30 mm can be processed using a laser cutter, allowing a variety of applications.

- Contour freedom: The laser beam heats the material locally, and the rest of the workpiece has little to no thermal stress. This allows for intricate contours/bends with little or no post-processing necessary. A laser cutter can be used for small lot sizes, large variant ranges, and prototype construction.

- High-quality cutting edges with ultrashort pulses make heat influence virtually undetectable, making a laser cutter ideal for the manufacture of intricate metal products.

- Accuracy: The strong beam achieves great precision, up to a fraction of a millimetre. A laser cutter creates a high standard and an exact product.

Laser cutting results in precise, clean cuts that don’t require the expense and time of further processing. It’s ideal for most metals common in industrial processing, is fast, repeatable and accurate, great for large runs. Short lead times and affordable prices make it an attractive option for a multitude of sheet metal fabrication needs.

Interested in laser cutting for your sheet metal project? Contact Calgary-based Innovative Manufacturing Source (IMS). Our team of knowledgeable, skilled, dedicated people offer unsurpassed service and product. We provide laser cutting and punching, custom sheet metal enclosures, precision sheet metal forming, welding and surface finishing. We serve you through in-house manufacturing capabilities completed on state-of-the-art equipment. Call us at 403.279.7702 for all your sheet metal needs.