A cable assembly is a critical aspect of an electrical system as the failure of a cable results in costly downtime. Most industrial manufacturers deal with occasional cable failure. What is the solution? How can manufacturers ensure that electrical processes run smoothly and workflow is maintained? A high-quality cable assembly and adherence to best practices are part of the answer.

What is a cable assembly?

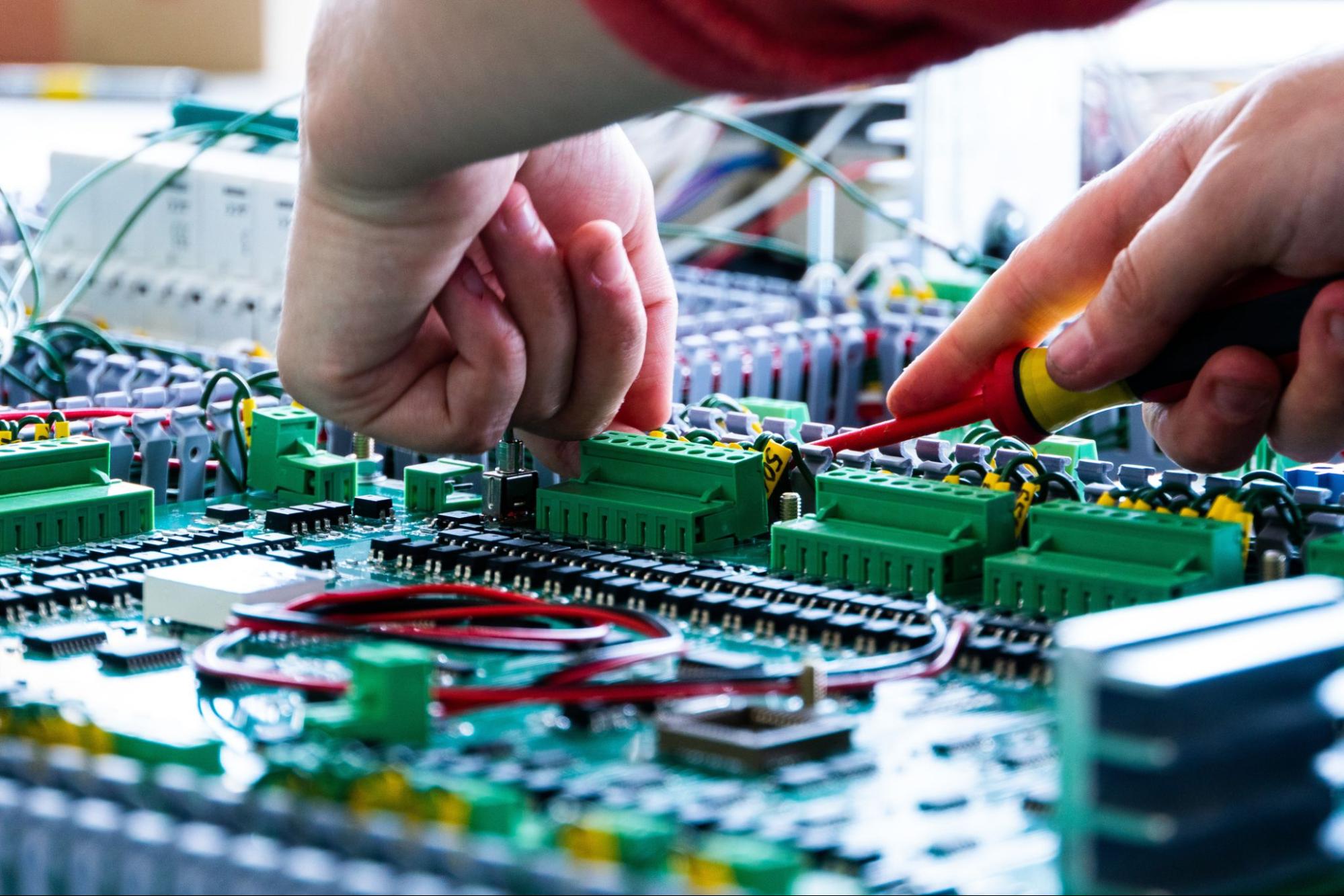

A cable is two or more conductors wrapped in a single jacket. Most cables consist of a positive wire (carries the electrical current), a neutral wire (completes the electrical loop) and a grounding wire (connects the system to the earth). A cable assembly, also called a cable harness or wiring loom, is a group of cables encased in a singular tube of material (rubber, vinyl or thermoplastic). The cables are grouped together in the required length and orientation, making them easier to install, replace, and maintain. A cable assembly may include different cable constructions, as well as varying sizes, colours and lengths depending on the application. The assemblies may be compiled with a sleeve or taped/bound with cable ties, grouping the cables together, protecting them and making them more compact.

An assembly may be fitted with various terminations, including plug or socket arrangements. Assemblies are used to connect a machine to a power, data or networking signal. These ready-to-install assemblies don’t require stripping or terminating to attach connectors, simplifying machine design. They reduce environmental damage and protect signal integrity from contamination from dirt/liquids, EMI and other electrical interference and impact or strain from pulling or tugging on the cables. This protection reduces the possibility of problems with the machinery due to issues such as shorts in the wiring. Cable assemblies are used in a variety of applications (mobile machinery, industrial automation, military, aerospace, oil and gas, and medical devices). The specific design depends upon its use and the needs of the user with custom designs available.

Best practices for managing cable assemblies and ensuring quality, reliable connections:

Cable assemblies unite cables, connectors and other connectivity components, delivering reliable signals and power connections between equipment units. Their importance to smooth and continuous operation demands the establishment of best practices. To maximize the performance of your cable assemblies:

- Choose a single reliable supplier: Find a manufacturer of high-quality cable assemblies who can design custom parts for your products and provide documentation/training on how to install these parts. Having a single reliable supplier of high-quality assemblies allows you to get answers and resolve problems quickly.

- Ensure your supplier has great service: Reliable, experienced cable manufacturers often offer automatic re-order and delivery of materials and parts. They also allow for control over your re-orders, enabling changes to meet the needs of your production line.

- Choose ready-to-install assemblies: An experienced, reliable cable provider ensures that all cabling parts and materials arrive ready to be installed (pre-packaged, bundled), allowing rapid installation with minimal errors. No need to cut, strip, assemble, solder or bundle wires. You simply follow a diagram to achieve installation.

- Check that your supplier provides training: Reputable custom cable providers make regularly scheduled visits to your production floor to train your workers/technicians in assembly and installation. They answer all questions, provide technical drawings and/or instructions for installation and identify areas where you may improve efficiency in your production.

- Confirm that the supplier labels, strips and colour codes the assemblies: To ease the installation of assemblies (allow technicians to select the right wires, connectors and/or assemblies), ask your provider to label and colour code the products.

Industrial manufacturers have to balance a number of different variables to make sure their production line runs smoothly. One of the biggest components of any manufacturing operation is ensuring that you have the right parts and raw materials when you need them. Consider working with a reputable, experienced custom cable assembly partner. They have the knowledge, experience and products to help keep your operation running smoothly.

Need a custom cable assembly supplier? Contact Calgary-based Innovative Manufacturing Source (IMS). Our team of knowledgeable, skilled, dedicated people offer unsurpassed service and product. We serve you through in-house manufacturing capabilities completed on state-of-the-art equipment. Call us at 403.279.7702 for all your cable assembly needs.